Used MANIA Micro 200 #293595679 for sale

URL successfully copied!

Tap to zoom

ID: 293595679

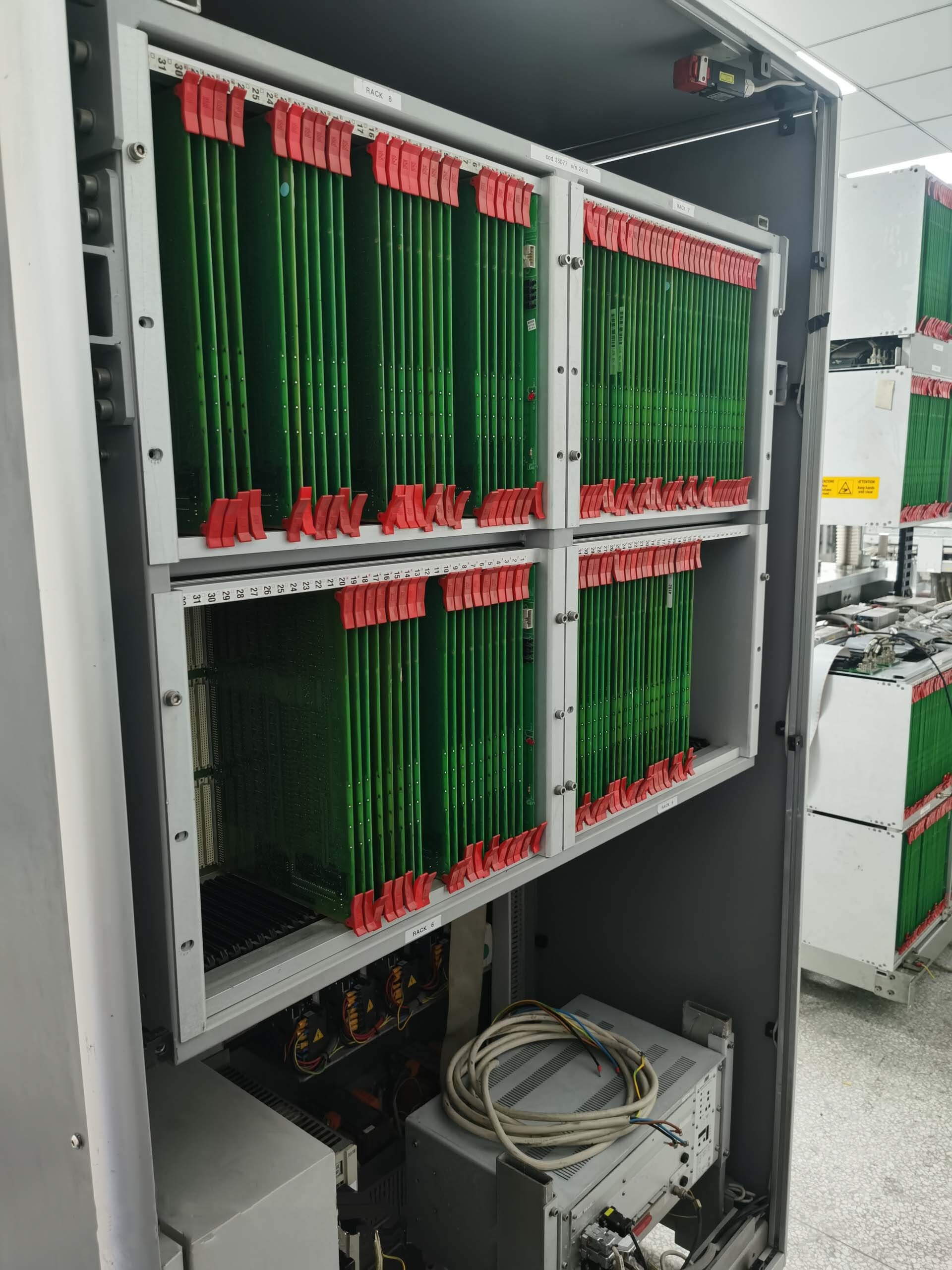

Vintage: 2004

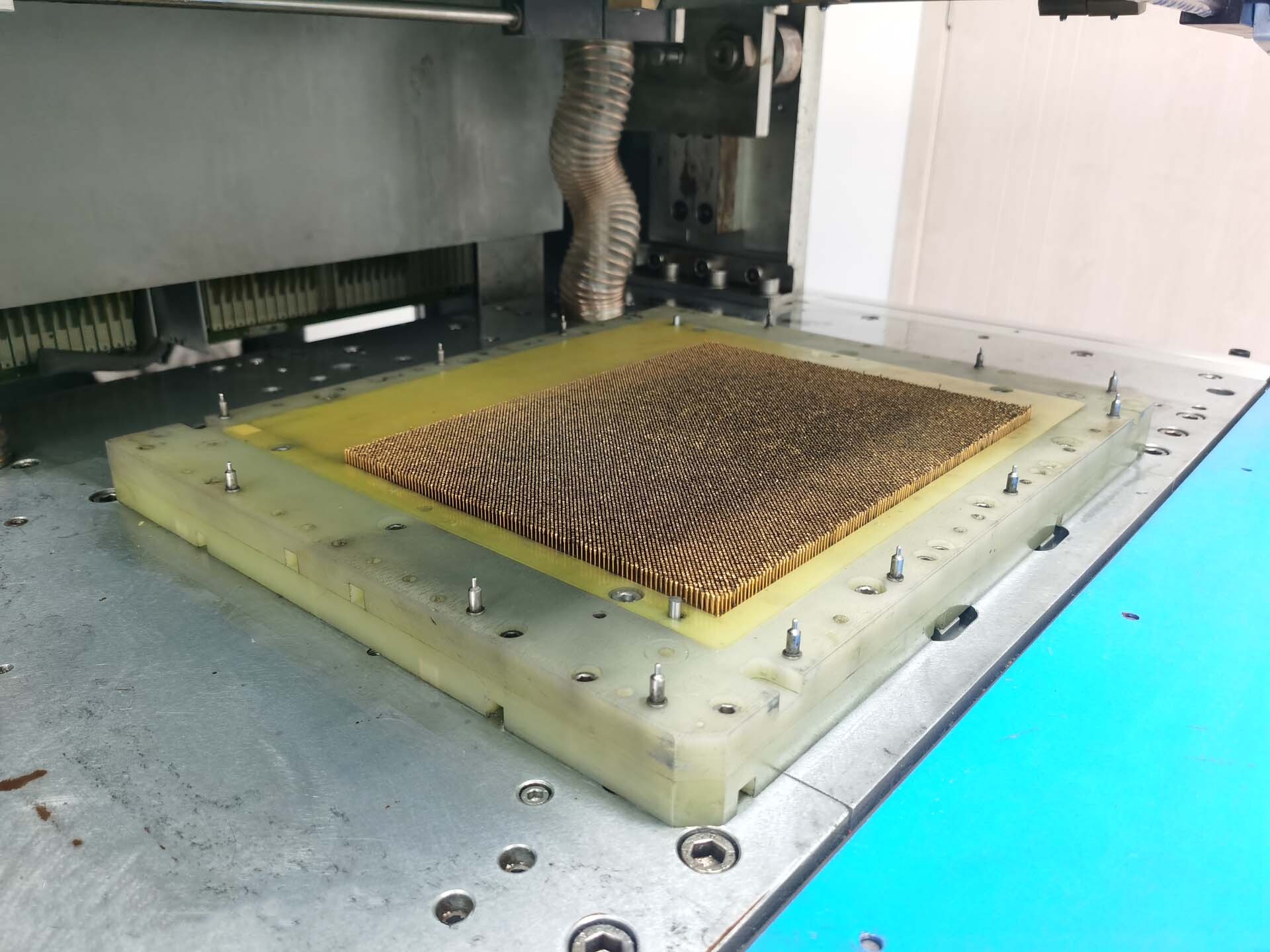

Bare Board Tester (BBT)

Tester area: 12.8" x 9.6"

Test grid: Double density (70 Mils)

2004 vintage.

MANIA Micro 200 is a complete PC board assembly and manufacturing equipment that is fast, accurate and highly capable. It is designed for production and prototyping of PC boards and offers high throughput, precision and reliability. The system begins with the insertion of components on a PC board. This is facilitated by a component placement head which has a variety of options for various components. The placement head has suction-cup tooling and precise location so that components are placed quickly, with accuracy and speed. The component placement head can also work with fine pitch components. Micro 200 uses a multi-head soldering unit, with multiple soldering heads that can perform different operations such as wave soldering, rework, and soldering. The machine also features multiple nozzle configurations and vision alignment, so that accurate soldering can be achieved. The vision alignment allows precise inspection of current solder joints. The tool also offers an automated depaneling process which enables quick prototyping, allowing precise cuts and separations of the connecting traces. The depaneling process is essentially a computer-aided machining (CAM) process which uses a diamond cutting tip to mechanically cut and route the board. In addition, the asset has a full-facet imaging (FFI) model. This equipment is used to inspect all sides of the PC board, providing a clear picture of the finished product. It uses a high resolution camera with brightly illuminated LED to capture a clear image of the board. Finally, MANIA Micro 200 has a full set of after-processing. This includes laser marking, SMT component reflow, mechanical analyzer, automated optical inspection (AOI), X-ray inspection and component sorting. This allows for thorough post-processing of finished PC boards. Overall, Micro 200 is a powerful system that offers a number of capabilities for efficient PC board assembly and manufacturing. It is a highly precise, reliable, and fast unit that is suitable for production and prototyping. It offers component placement, soldering, depaneling and imaging, as well as multiple post-processing operations. This makes it an effective solution for PC board assembly and manufacturing.

There are no reviews yet