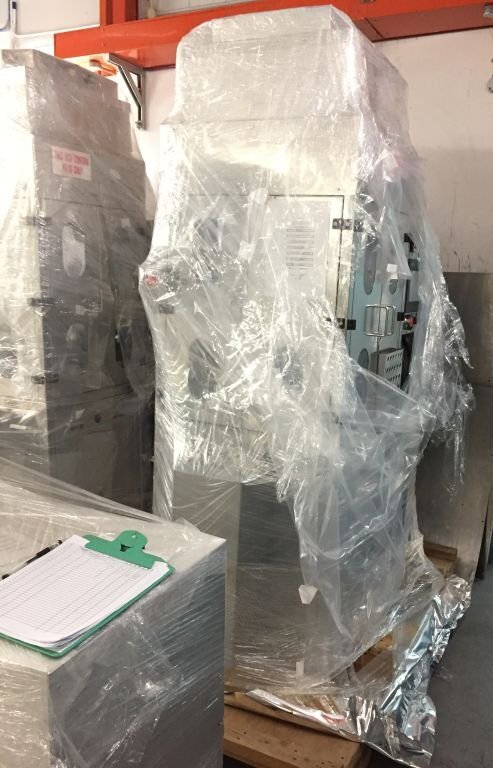

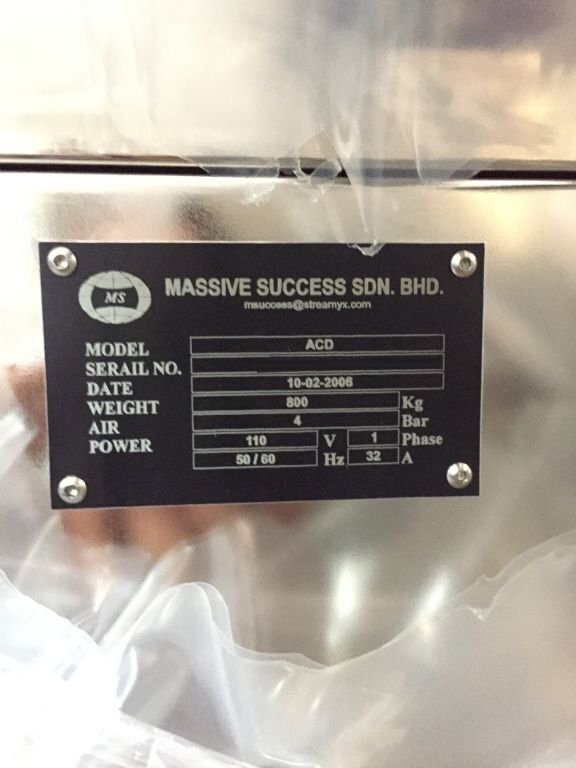

Used MASSIVE SUCCESS SDN. BHD. ACD #9315983 for sale

URL successfully copied!

Tap to zoom

MASSIVE SUCCESS SDN. BHD. ACD is a PC Board Assembly and Manufacturing equipment created to provide an automated and efficient solution for manufacturers of high-quality circuit boards. The system is designed to facilitate the assembly and manufacture of various electronics components such as transistors, resistors, capacitors and other electrical components. The unit is capable of performing multi-level testing for accuracy, reliability and consistency of each manufactured part. ACD machine is composed of several functions that operate collaboratively to provide an efficient and repeatable process for reliably manufacturing various electronic components. The key elements of MASSIVE SUCCESS SDN. BHD. ACD tool include an automated PCB layout predictor tool, an automated component placement asset, an integrated inspection model, a multi-level testing equipment for assessing quality criteria, and an array of automated software tools for customizing individual assembly and manufacturing processes. The automated PCB layout predictor tool is a powerful yet easy to use tool that allows users to create various PCB layouts from existing electronic devices. The tool incorporates numerous features such as component placement, assembly wiring, and circuitboard checking. This contributes to a production cycle which is both reliable and cost effective. The automated component placement system of ACD unit has been designed to handle the transfer and placement of components at specific locations on a board. It is fitted with safety sensors to ensure that components are not placed in different parts or moved to other areas of a board. Additionally, an integrated inspection machine inspects parts for defects in material, design and dimension. This tool ensures that components meet the necessary standards prior to assembly and avoids the need for repairs and rework. The multi-level testing asset ensures parts are tested for accuracy, reliability and consistency. This can be done manually or using automated processes. Finally, the model can be equipped with various automated software tools for customizing individual assembly and manufacturing processes. These tools allow users to manage and track the progress of production processes, to automate component purchasing, to customize assembly and manufacturing schedules, and to prepare reports for auditing and reporting purposes. In summary, MASSIVE SUCCESS SDN. BHD. ACD provides a powerful, automated and efficient solution for the efficient and reliable assembly and manufacture of PCBs. The automated component placement equipment, integrated inspection system, multi-level testing unit and customizing software tools ensure an efficient, reliable and repeatable production cycle while saving time and money.

There are no reviews yet