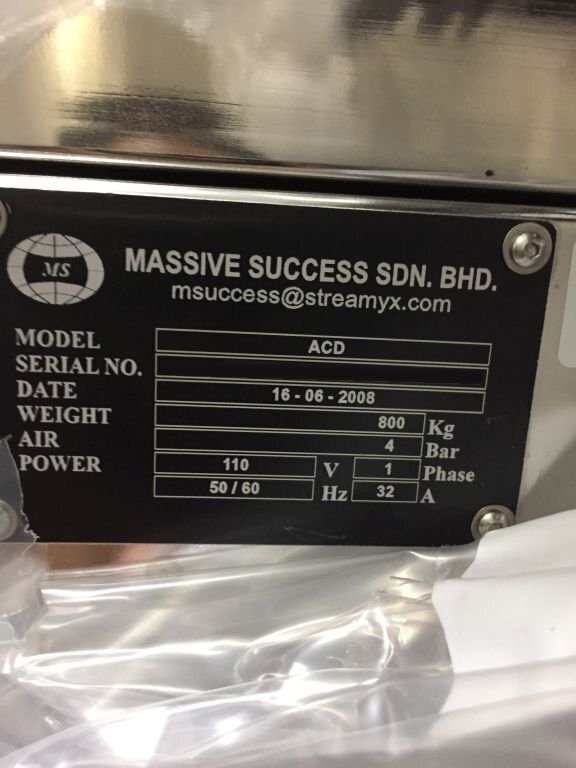

Used MASSIVE SUCCESS SDN. BHD. ACD #9315986 for sale

URL successfully copied!

Tap to zoom

MASSIVE SUCCESS SDN. BHD. ACD is a powerful, full-scale automation equipment for pc board assembly industrial, and manufacturing applications. It is a comprehensive electronic manufacturing solution that enables efficient production of boards of sizes ranging from small-sized boards containing one component to larger boards containing hundreds of components. ACD is a fully modular, state-of-the-art system designed to increase manufacturing efficiency and reduce costs. It is comprised of a number of core components built on a integrated platform of hardware and software. These include material handling robots, pick-and-place machines, reflow ovens, conveyors, vision systems, Data Acquisition Unit (DAS) Modules, Advanced Process Control (APC) Modules, and other components. MASSIVE SUCCESS SDN. BHD. ACD machine is designed with multiple standard tracks to ensure that components from multiple sources can be processed in a coordinated manner. It features advanced implementation of process scheduling, optimization of workflows, job-oriented workflow management and report generation for efficient workflow analysis. The tool is also capable of auto-loading, commencing, tracking and finishing production jobs in a single asset. ACD software is further equipped with features such as tracking and traceability, material resource planning (MRP), and warehouse automation which enhances the model's performance and scalability. The integrated software provides a solid platform for the development of inspection, repair, and testing routines. It can also be used to monitor, control, and manage production monitoring systems. MASSIVE SUCCESS SDN. BHD. ACD equipment is designed with a user-friendly graphical interface which provides an intuitive user experience. It can be accessed from any location, allowing users to monitor the entire system from anywhere. Additionally, it is engineered with built-in analytics and data capture capabilities which enable users to collect data from all parts of the unit. This data can then be used for making production decisions, conducting analytics, and optimizing the machine's performance. ACD can be used in a variety of different production environments including cleanrooms, and it is suitable for all levels of electronics assembly. It offers robust, reliable, and accurate performance, which helps manufacturers reduce wastage, improve product quality, and optimize production processes.

There are no reviews yet