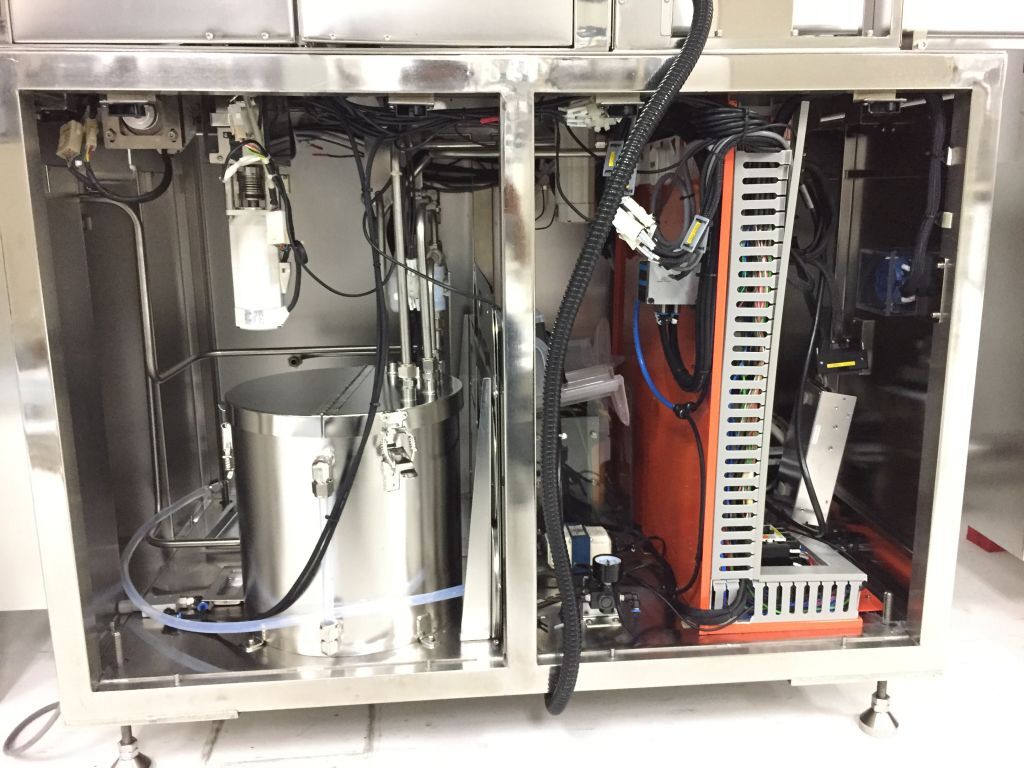

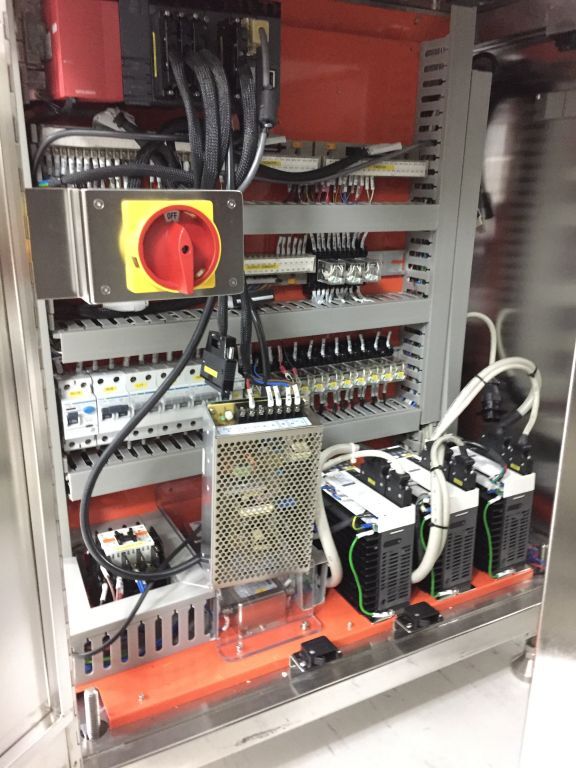

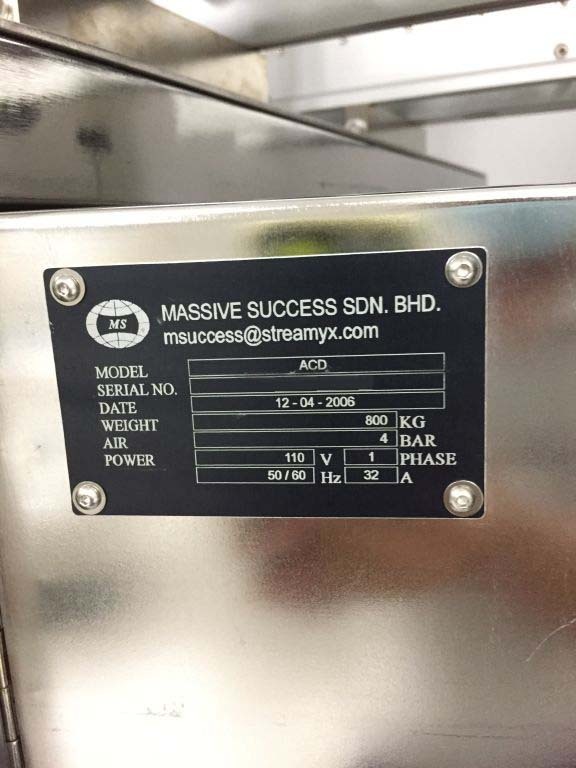

Used MASSIVE SUCCESS SDN. BHD. ACD #9315996 for sale

URL successfully copied!

Tap to zoom

MASSIVE SUCCESS SDN. BHD. ACD (Advanced Component Design) is an advanced pc board assembly and manufacturing equipment designed to meet the highest quality standards and production objectives. It is capable of producing complex assemblies with superior quality and high accuracy. ACD's core features include automated management of pc board design, fabrication, assembly, and quality assurance. It is suitable for a variety of applications, including automotive, industrial, medical, and consumer applications. The system is based on an open and distributed architecture, which allows it to easily integrate with various software and hardware systems. It allows users to efficiently manage the entire pc board manufacturing process from design to production. MASSIVE SUCCESS SDN. BHD. ACD's powerful graphical user interface enables advanced design verification features to ensure quality and accuracy. It also provides automated design optimization, to reduce manufacturing time and cost. The unit is designed to enable the maximum level of standardization in design and manufacturing. It supports multiple pc board sizes and architectures, as well as a variety of component technologies and placement types. It allows users to customize and adjust process parameters to best fit the production goals. It provides comprehensive support for all processing stages, including copper plating, masking, soldering, and soldermasking. The machine features advanced SMT (Surface-Mount Technology) capabilities, which enable cost-effective and accurate component placement. It supports a wide range of component types and sizes, and provides efficient component recognition and placement. Additionally, it includes comprehensive real-time analysis, to ensure precise compliance with placement and matching standards. For assembly, it includes sophisticated algorithms to minimize manual labor and ensure efficient production, as well as automated quality control. It provides comprehensive monitoring of the entire assembly process and complete documentation of component test results. Additionally, it provides remote access and real-time updates, as well as automated recording of pc board status in multiple locations. In short, ACD is a powerful, user-friendly tool for pc board assembly and manufacturing. It optimizes the entire pc board design and manufacturing process, while ensuring high quality and accuracy. Its advanced features enable cost savings and faster time-to-market, making it an ideal solution for a wide range of applications.

There are no reviews yet