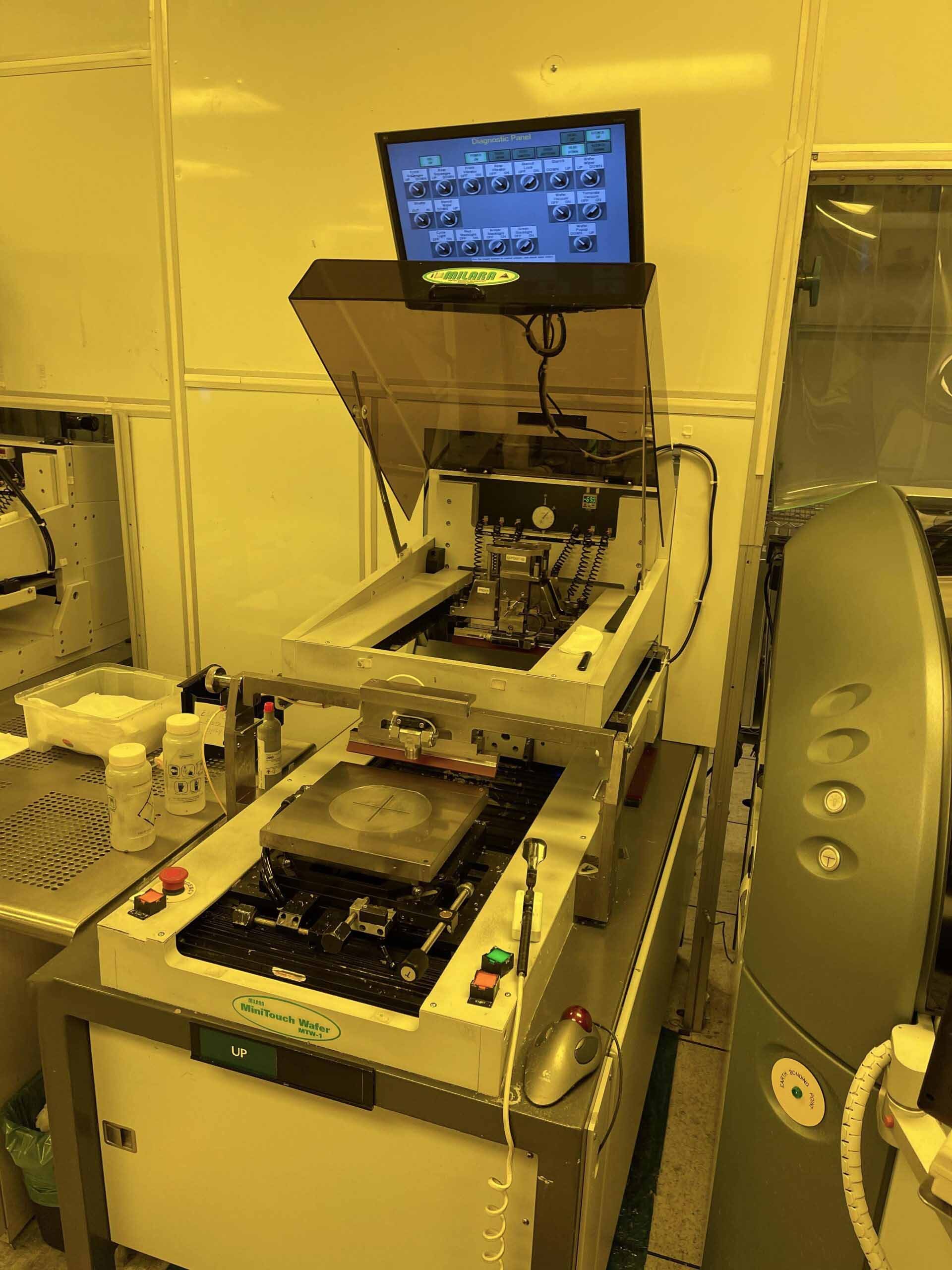

Used MILARA MTW-1 #9395648 for sale

URL successfully copied!

Tap to zoom

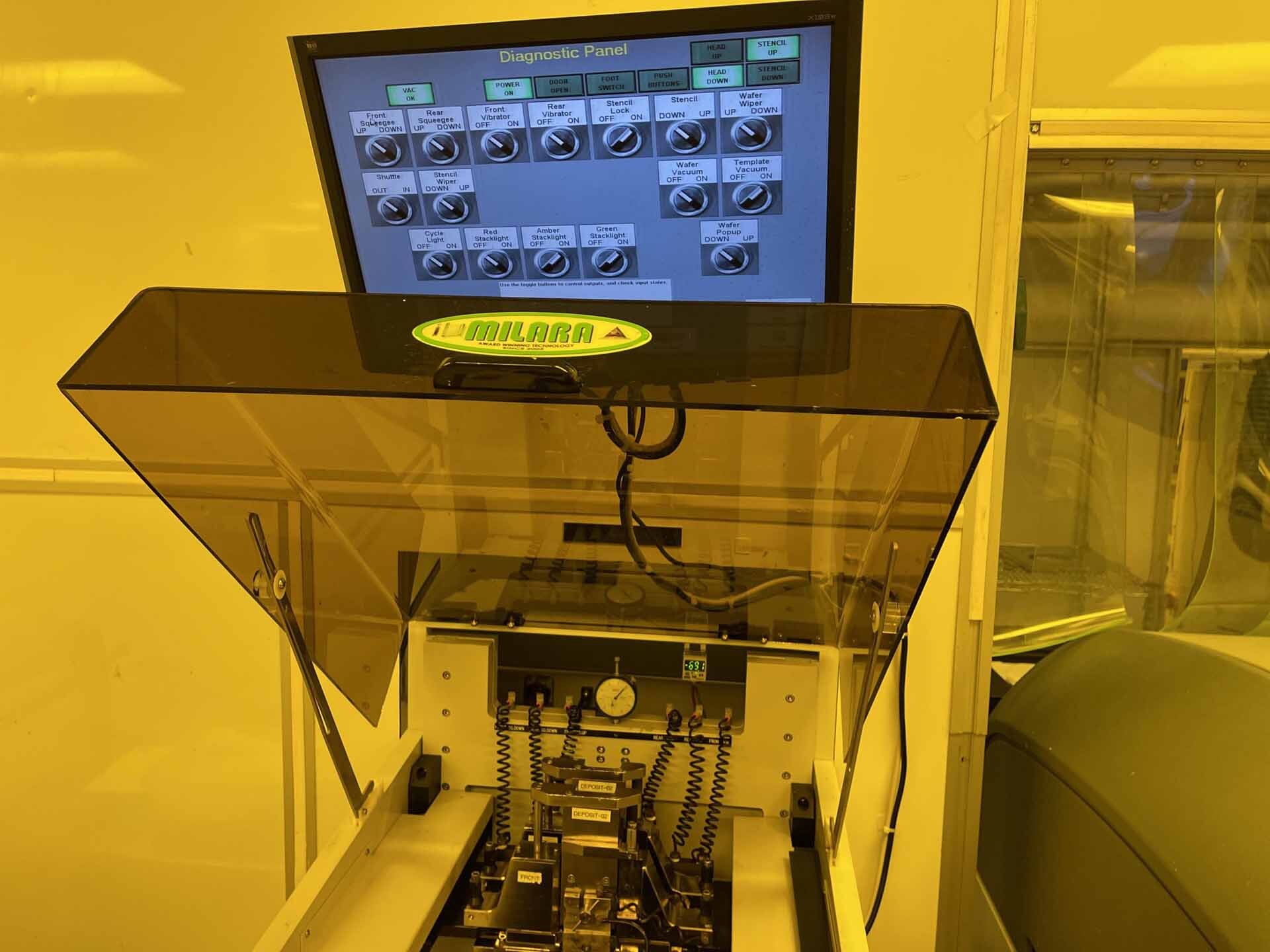

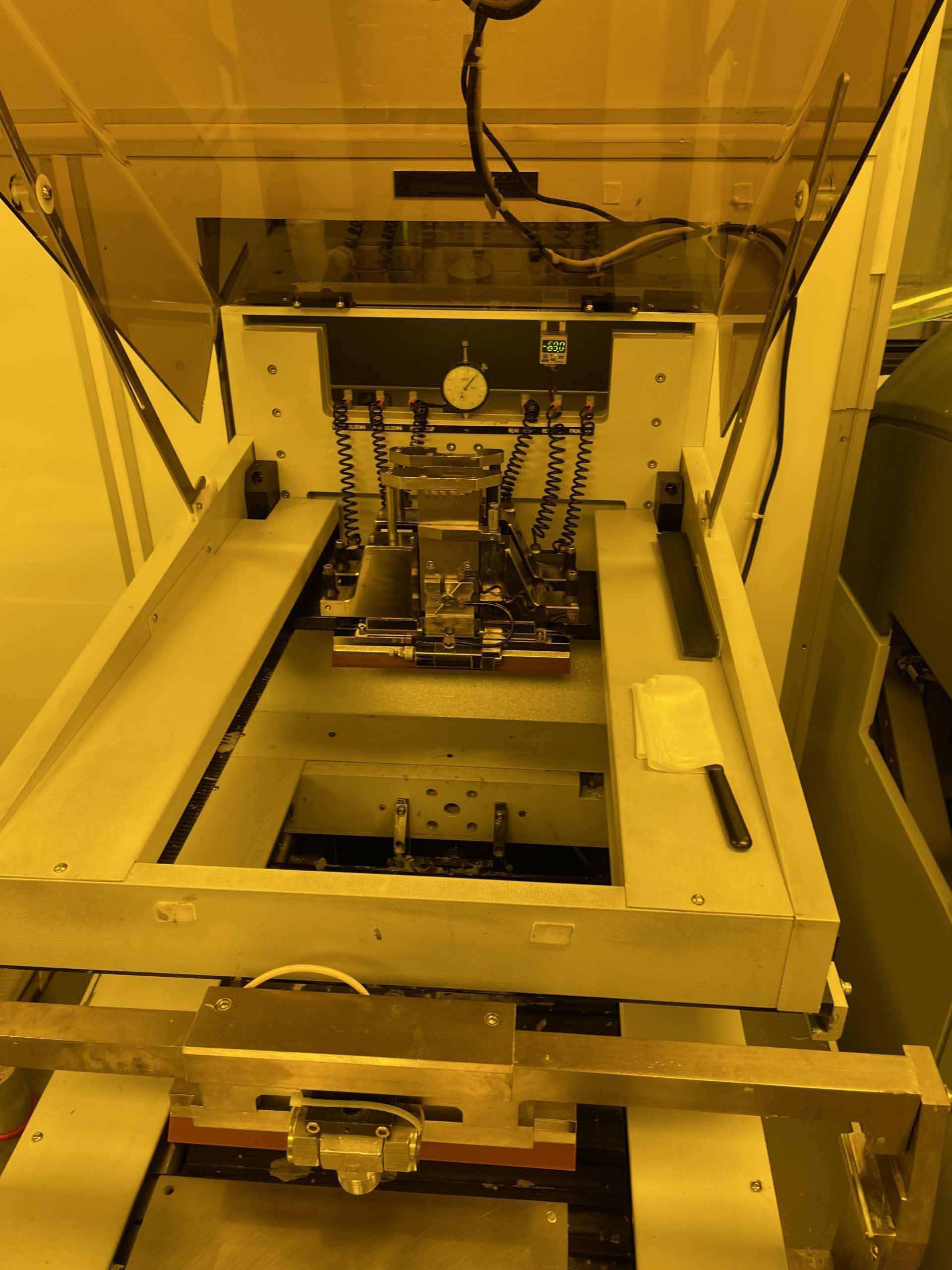

MILARA MTW-1 is an innovative pc board assembly and manufacturing equipment designed to automate the tedious task of producing printed circuit boards (PCBs) in a fast, efficient, and cost-effective way. This state-of-the-art system combines advanced software solutions with smart digital interfaces as well as built-in automated features that allow users to customize their design processes. MTW-1 unit comprises of three main components: the Machine Vision, the Machine Controller, and the Machine Tooling. The Machine Vision component consists of a user-friendly software designed to identify and track patterns, colors and shapes on printed circuit boards (PCBs). This component allows for automated inspection of the PCBs and to identify any potential defects. This helps in automating the bug tracking process, which in turn boosts the reliability of the PCBs. The Machine Controller is the core of MILARA MTW-1 machine. It allows for controlling the machines and various processes, like machining, drilling, welding, riveting, painting and much more. The controller also provides comprehensive control of the various components in the tool, like power inputs, drive motors, cooling systems, and more. This allows users to produce more accurate and precise boards with better handling of the mechanical assembly processes. The Machine Tooling component is a selection of various tools and machines specific for different fabrication processes. It includes tools such as routers, vertical mills, end mills, drills, drill presses, and riveters that are used in the assembly process. The tools are accurately calibrated and can be operated with high precision to give superior results. Overall, MTW-1 is an excellent choice when it comes to automating the design and manufacturing of printed circuit boards. It's user-friendly and intuitive software solutions make it easier to produce accurate and reliable PCBs, while the automated processes help reduce time, cost, and effort. This asset excels in producing excellent PCBs with high efficiency and time savings.

There are no reviews yet