Used MINAMI MK-250 #119300 for sale

URL successfully copied!

Tap to zoom

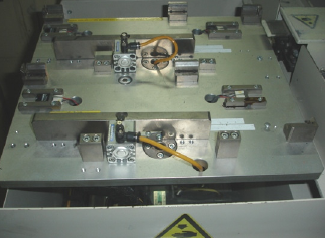

MINAMI MK-250 is a pc board assembly and manufacturing equipment built to provide high-speed production and testing of printed circuit boards. The system consists of several main components, such as a soldering machine, a testing station, an assembly station, and a parking station. The soldering machine solders components on pc boards. It is controlled by a programmable logic controller, which can make it possible to modify the soldering parameters for different components and substrates. The testing station checks the correct positioning of the components by measuring their electrical parameters. It also checks for any shorts between the components on the board. The assembly station is used for assembling the board with other mechanical components. It is automated and has the ability to adapt to different products and designs. Finally, the parking station is used for managing the process and stocking of boards and components. The unit comes with a selection of user-friendly software, which enables users to input programmable logic controller parameters and control the overall production process. It also provides an online display of production performance and a graphical interface to aid the users' setup and troubleshooting. MK-250 machine is equipped with an on-line programmable logic controller maintenance tool that updates the asset with new programs and components. In addition, it is equipped with multiple safety mechanisms to reduce the risk of malfunction and component damage. The model is designed to easily integrate with other assembly and production systems, enabling manufacturers to maximize output through efficient automation. MINAMI MK-250 also provides component placement accuracy of ±25μm, as well as total production cycle time of approximately 1.5 seconds. This equipment is ideal for handling small and medium-volume production needs with excellent accuracy and speed.

There are no reviews yet