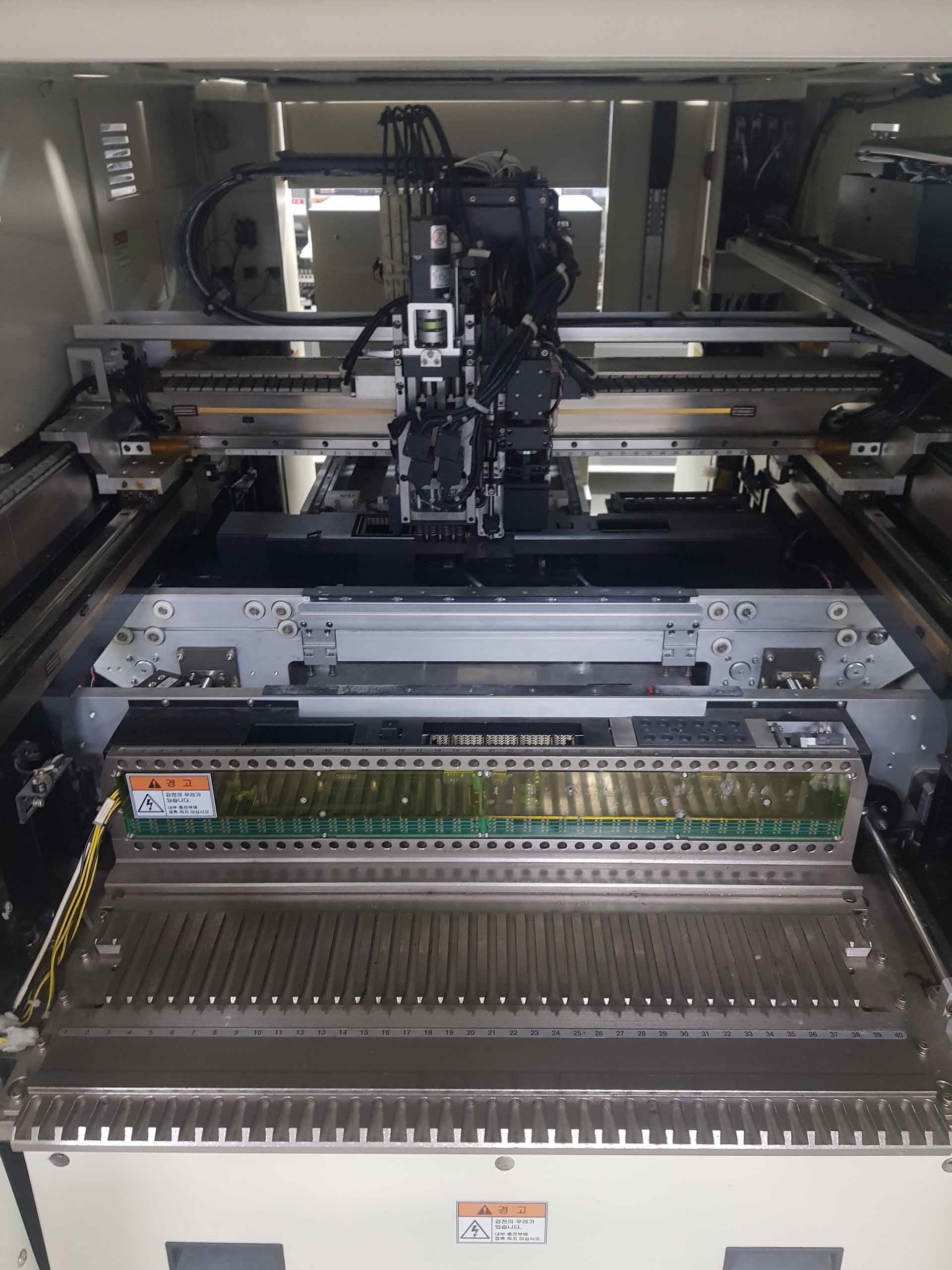

Used MIRAE MPS-1025PC #9246818 for sale

URL successfully copied!

Tap to zoom

MIRAE MPS-1025PC is a complete PC board assembly and manufacturing equipment designed to meet the needs of the modern electronics manufacturing industry. This advanced system is capable of handling a full range of printed circuit board components, including traditional surface mount components as well as the latest chip-on-board and micro leadframe devices. MPS-1025PC is equipped with a dual-axis vision unit that enables high-speed and simultaneous print registration recognition. This vision machine also features real-time defect recognition technology. Additionally, the tool has highly efficient component placement heads that consistently achieve high throughput and accuracy. The asset is capable of placing components from 01005 to 25mm square. This model also features a high-performance pick and place machine that utilizes a rigid frame design and advanced vision equipment to ensure excellent placement accuracy. The system can handle multiple component types and packages including 0603 chips, PLCCs, SOICs, QRPs, MLFs and SIMMs. The machine is equipped with a high-efficiency vacuum unit and can place components with an accuracy of up to +/- 0.05mm. In addition, MIRAE MPS-1025PC has an integrated placement verification machine that allows for the production of high-quality boards without the need for additional inspection processes. This tool is equipped with a camera asset and image processing for the real-time inspection of component placements. It also includes software for controlling and calibrating the placement verification model. MPS-1025PC is a highly automated and efficient equipment designed to meet the needs of modern electronic assembly businesses. It offers a selection of tools and features that ensure high throughput and accuracy and ultimately help to reduce costs and increase yield. Furthermore, its high-tech vision system and verification technologies guarantee the highest quality boards.

There are no reviews yet