Used MIRAE MX 400L #9118167 for sale

URL successfully copied!

Tap to zoom

ID: 9118167

Vintage: 2010

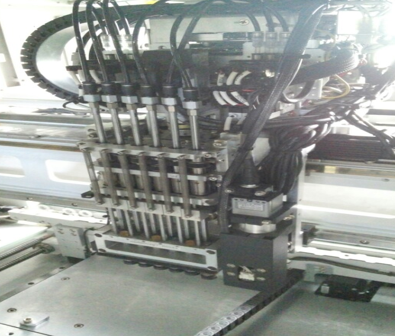

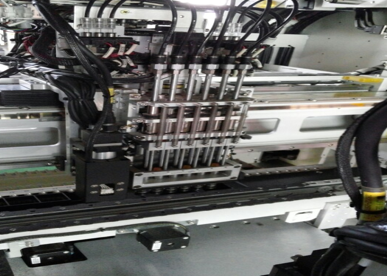

Chip mounter

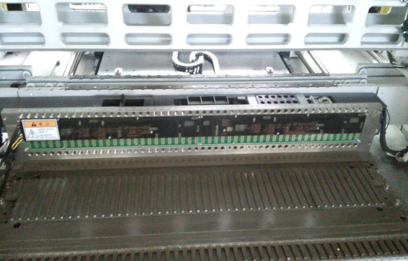

Feeders:

(20) 8mm

(3) 12mm

16mm

24mm

Feeder cartridge

Nozzles

2010 vintage.

MIRAE MX 400L is a complete pc board assembly and manufacturing equipment made from the highest quality components. The system has been designed to meet the demands of modern electronics assembly and manufacturing, providing a comprehensive set of features to streamline the process. The core of the unit is a robotic loading/unloading (L/UL) machine that can quickly and accurately place components on and off of the boards with a high degree of precision. The tool also utilizes a vision asset to detect component placement and perform component-level inspection. The vision model is integrated into the robotic L/UL equipment to provide fast, reliable, and accurate results. MIRAE MX400L employs advanced features such as automated stencil cleaning and tooling, as well as nozzle height correction technology. Furthermore, a unique conveyance system is integrated into the platform that allows for the efficient and smooth transfer of boards from production line to production line. The unit also includes a host software that allows for easy integration of process control and machine configuration. In terms of PC board assembly, MX 400L can accommodate boards up to 400 x 400mm (16x16in), with intricate vises that securely hold the boards in place during assembly. The machine also includes a high-capacity, high-speed chip shooter, which operates with a speed of up to 25 components per second and can place components ranging from 0201 to 0603 size. The chip shooter is backed up by an 8-nozzle head that provides superior accuracy with an accuracy of ±0.03mm (±0.001 in). MX400L is also equipped with a high-quality reflow oven to reflow components onto boards. The oven is capable of reaching temperatures of up to 260°C (500°F) and includes a full range of temperature profiles to ensure a consistent and reliable soldering process. The tool further includes a visual inspection option to check the quality of the components and boards after the assembly process. MIRAE MX 400L is also designed to increase production yields and reduce the possibility of assembly errors. It is equipped with a SMEMA-compliant material handling asset that uses a barcode reader to ensure that the correct part type is assigned to the correct assembly location. Additionally, the model is designed to generate statistical process control (SPC) charts to help manufacturers analyze and improve their processes. Overall, MIRAE MX400L is a highly advanced PC board assembly and manufacturing equipment that is capable of delivering reliable and efficient electronics assembly and manufacturing operations. The system is equipped with features such as a robotic loading/unloading unit, an integrated vision machine, an automated stencil cleaning tool, and a high-capacity chip shooter, all designed to reduce downtime and improve production yields.

There are no reviews yet