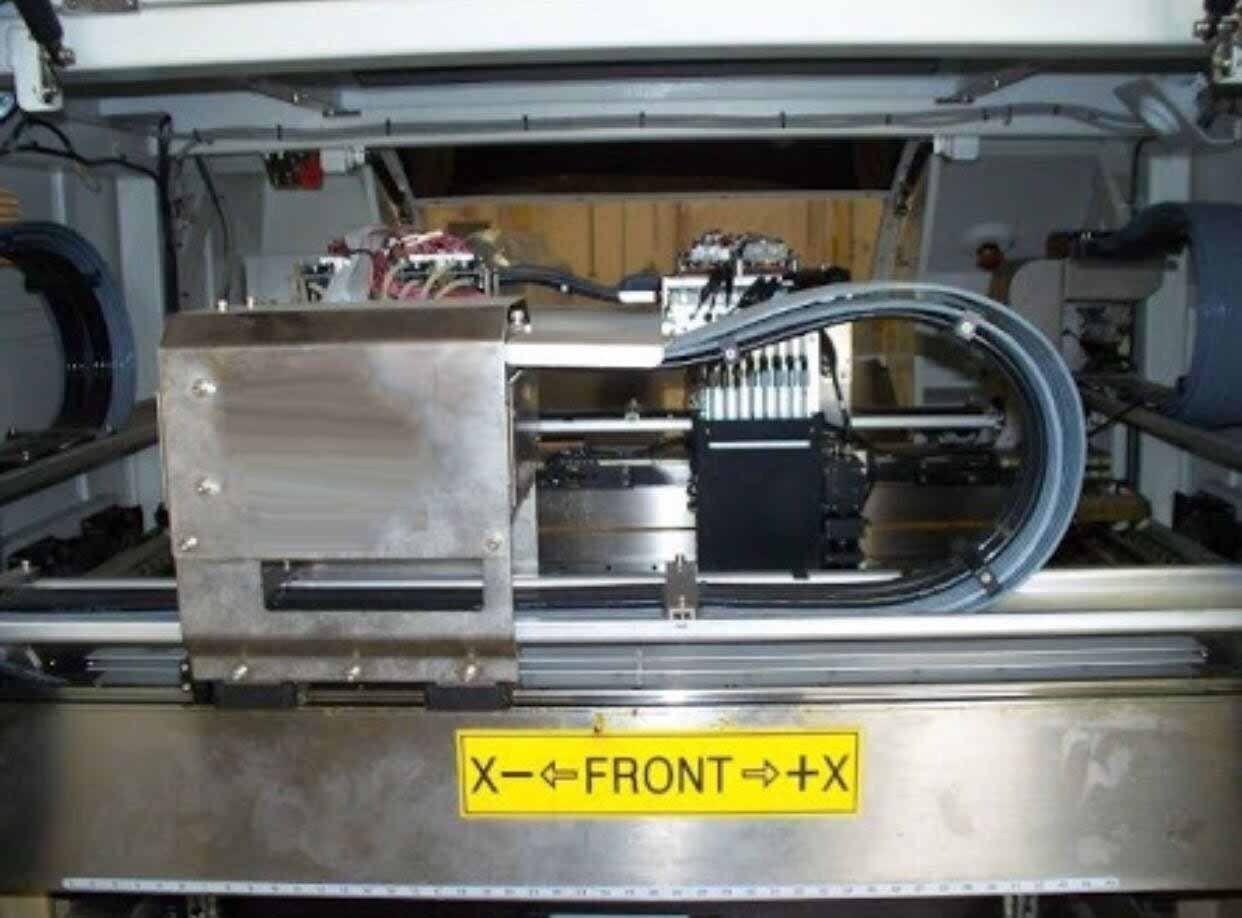

Used MIRAE / QUAD MPS-1010 / MPS-1010P #9162442 for sale

URL successfully copied!

Tap to zoom

ID: 9162442

Vintage: 2000

Chip shooters

Assembly time: 0.096 seconds / chip, 28000 Cph (IPC-9850)

Placement accuracy:

Chip: 0.1 / QFP 0.08

Substrate size: Mm 30x50 - 410x360 (0.4 - 4.0 mm)

Component range: 1005 - 18x18

Resolution:

XY-axis: 0.001 mm

Posted titles R: 0.044 degrees

Posted titles Z: 0.0035

Transmission direction: Left -> right (standard)

Theoretical speed: 24000 Cph

2000 vintage.

MIRAE / QUAD MPS-1010 / MPS-1010P is a complete industrial pc board assembly and manufacturing solution. It is a modular equipment that provides automated component placement as well as inspection, testing, and soldering. The system features a vision unit that can read and verify component placement and solder joints. It is capable of single and multi-layer placements, and supports components down to 01005µm and up to 50mm. It also has a range of transport solutions, including tape and reel, tray and tube. QUAD MPS-1010 / MPS-1010P has a unique circuit board optimization process to ensure accuracy and reliability. It can manage board sizes up to 1,500 x 1,000 mm, and can process up to 2,000 components per hour. The machine's advanced board traceability ensures full traceability from component to assembly. MIRAE MPS-1010 / MPS-1010P is equipped with a Dynamic Error-Proofing Tool (DEV) that automatically detects, notifies, and corrects user mistakes. This allows for an efficient and error-free production in a safe and secure workplace environment. It also features an intuitive and easy-to-use GUI that can be used to set up new component placements, traceability, inspection, and soldering operations. In addition, the asset offers a wide selection of specialty functions such as selective soldering, automatic cleaning, dispensing, and laser marker integration. These features, combined with the model's efficient operations and high precision, make MPS-1010 / MPS-1010P an ideal solution for board assembly and manufacturing.

There are no reviews yet