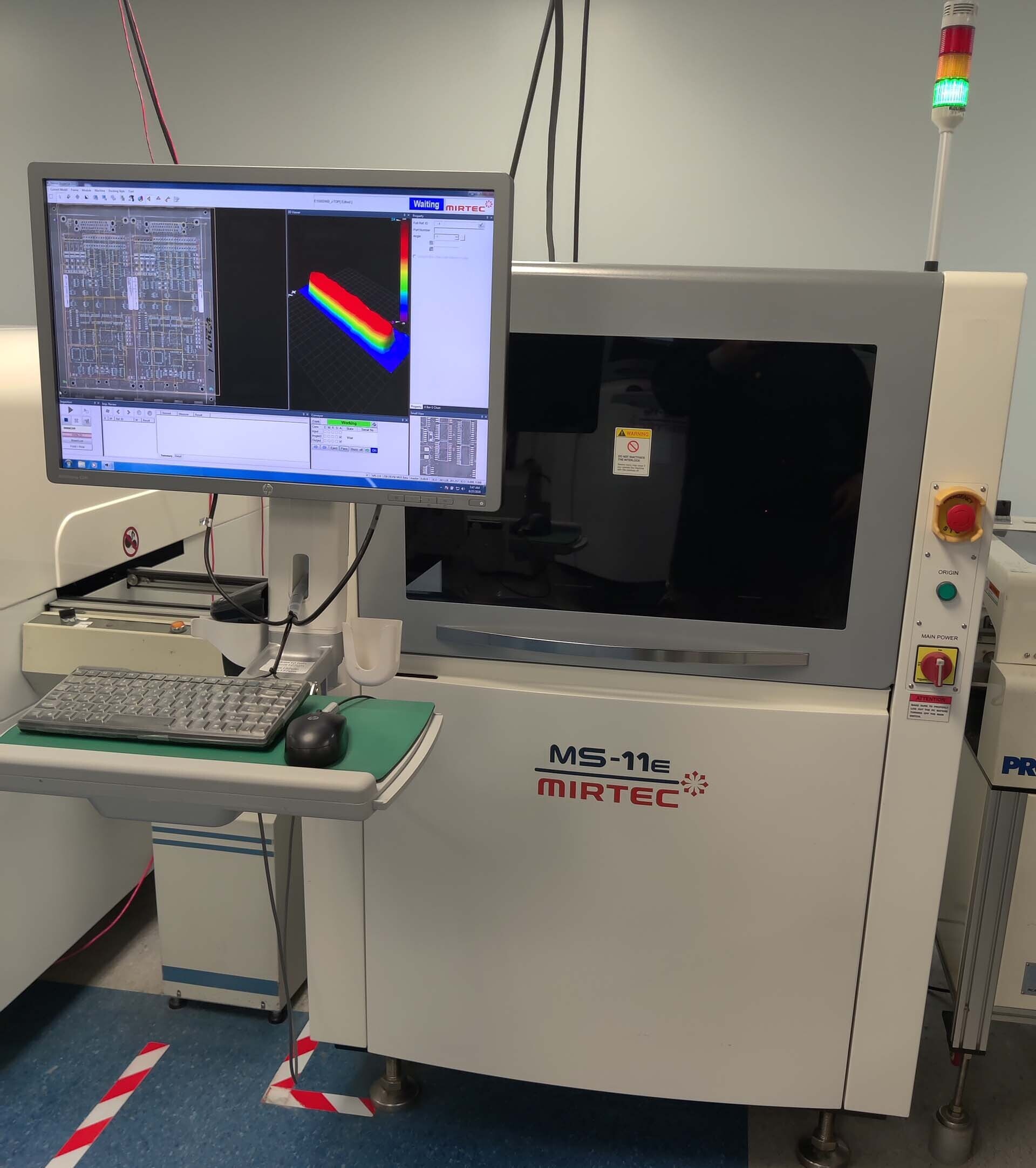

Used MIRTEC MS-11E #9302317 for sale

URL successfully copied!

Tap to zoom

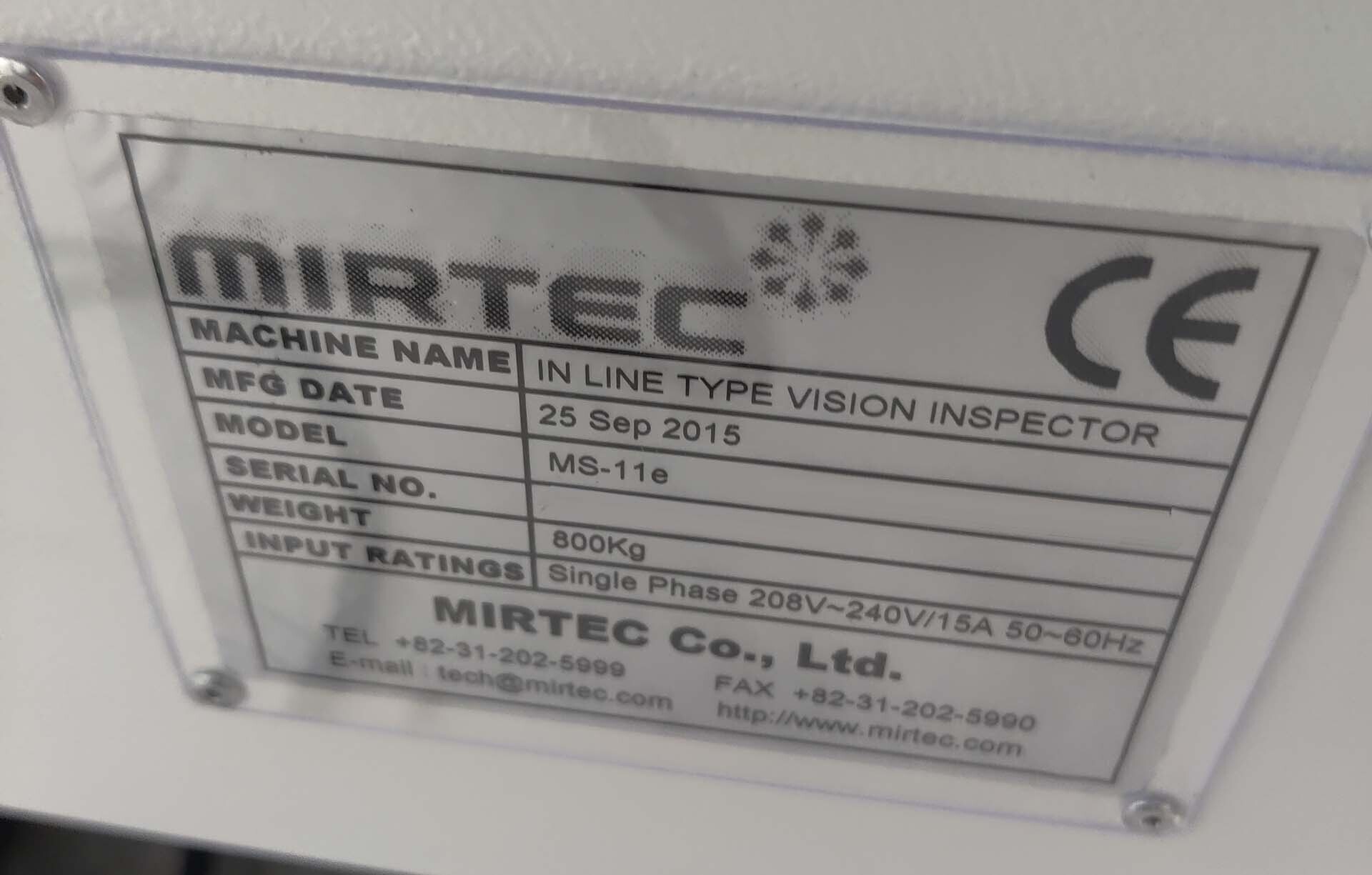

ID: 9302317

Vintage: 2015

Solder Paste Inspection (SPI) system

Lens configuration: PRECISION Telecentric compound lens design

Laser PCB warpage compensation: 1 µm / Point

PCB Top side clearance: 25 mm

PCB Bottom side clearance: 25 mm (Option: 50.8 mm)

Maximum PCB warpage: ± 3 mm

Barcode reader: 1D / 2D PCB Barcode reading capability

Camera type (Option): Top-down camera

Robot positioning system:

X/Y-Axis: PRECISION Closed loop AC SERVO Drive motor system

Resolution: 1 µm

Repeatability: ± 10 µm

Power requirements: Single Phase, 200-240 V, 50/60 Hz, 1.1 kW

Air requirements: 5 Kgf / cm² (0.5 Mpa), (71 PSI)

Image Transfer Technology:

15 Mega pixel camera: 3904 x 3904 Pixels

CoaXPress: 120fps

4 Mega pixel camera: 2048 x 2048 Pixels

Camera link: 180fps

Vision system (FOV Size):

15 Mega pixel camera: 3904 x 3904 Pixels

Option 1: Pixel resolution: 20µm

Option 2: Pixel resolution: 15µm

Option 3: Pixel resolution: 10µm

4 Mega pixel camera: 2048 x 2048 Pixels

Option 1: Pixel resolution: 15.71µm

Option 2: Pixel resolution: 11.78µm

Maximum inspection speed:

15 Mega pixel camera: 508ms/FOV

Option 1: Pixel resolution: 20µm

Option 2: Pixel resolution: 15µm

Option 3: Pixel resolution: 10µm

4 Mega pixel camera: 387ms/FOV

Option 1: Pixel resolution: 15.71µm

Option 2: Pixel resolution: 11.78µm

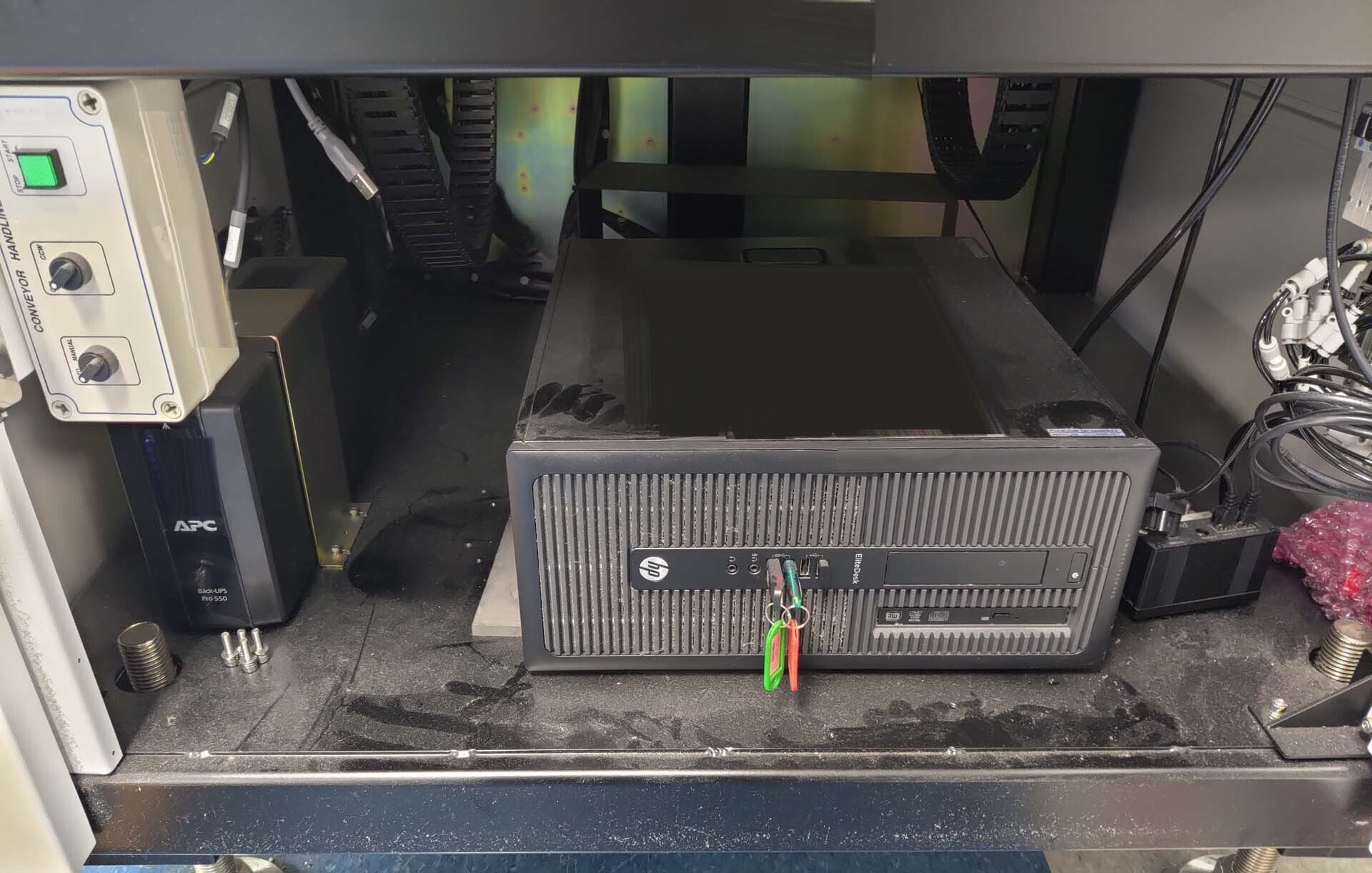

(4) HP CD

Inspector

(2) Conveyor belts

Inspector: 2520 mm

Gray card

Tension monitor mount: 24 mm

Fuse:

Glass tube: 2A

(3) Glass tubes: 5A

Glass tube: 10A

(2) 14 Pin SMEMA communication cables

Manual:

User

Maintenance

2015 vintage.

MIRTEC MS-11E equipment is a high-performance PC board assembly and manufacturing system. The unit utilizes a powerful combination of efficient software and advanced hardware components, allowing manufacturers to rapidly produce high-quality PC boards. The software used with the machine provides an easy to use graphical user interface for programming, diagnostics, and simulation of PC board manufacturing processes. The software is highly reliable, and incorporates features such as automatic error detection to greatly reduce the potential for errors during programming and manufacturing processes. The hardware components used in MS-11E tool are designed to provide precise control over the assembly and manufacturing process. The pick and place servo asset is capable of up to 6900 µm lead accuracy and a precise movement of up to 500 mm2/s for precise alignment of the parts. The vision model is capable of detecting and inspecting small variation and component misalignments, enabling greater flexibility when assembling components. Additionally, the vision equipment enables automatic optical alignment and soldering to achieve high-quality boards. The heated stage of MIRTEC MS-11E system allows for quick soldering of components, utilizing different soldering techniques such as SMT, through-hole components, and pin-in-paste. The stage utilizes fast, reliable, and high-precision soldering operations, allowing for high productivity and quality assurance. The conveyance unit included in MS-11E machine ensures smooth and fast transitions between board stages, and features a loading tool designed for the optimal exchange of boards between manufacturing stages. The built-in safety mechanism of the transport asset ensures that any components that may scatter are collected in a dust collector, improving safety and quality. MIRTEC MS-11E model ensures high accuracy in the production of PC boards through the use of its advanced features. With its reliable software, precise hardware components, fast heated stage, and efficient conveyance equipment, the system enables accurate and repeatable results for manufacturers in the assembly and manufacturing process of PC boards.

There are no reviews yet