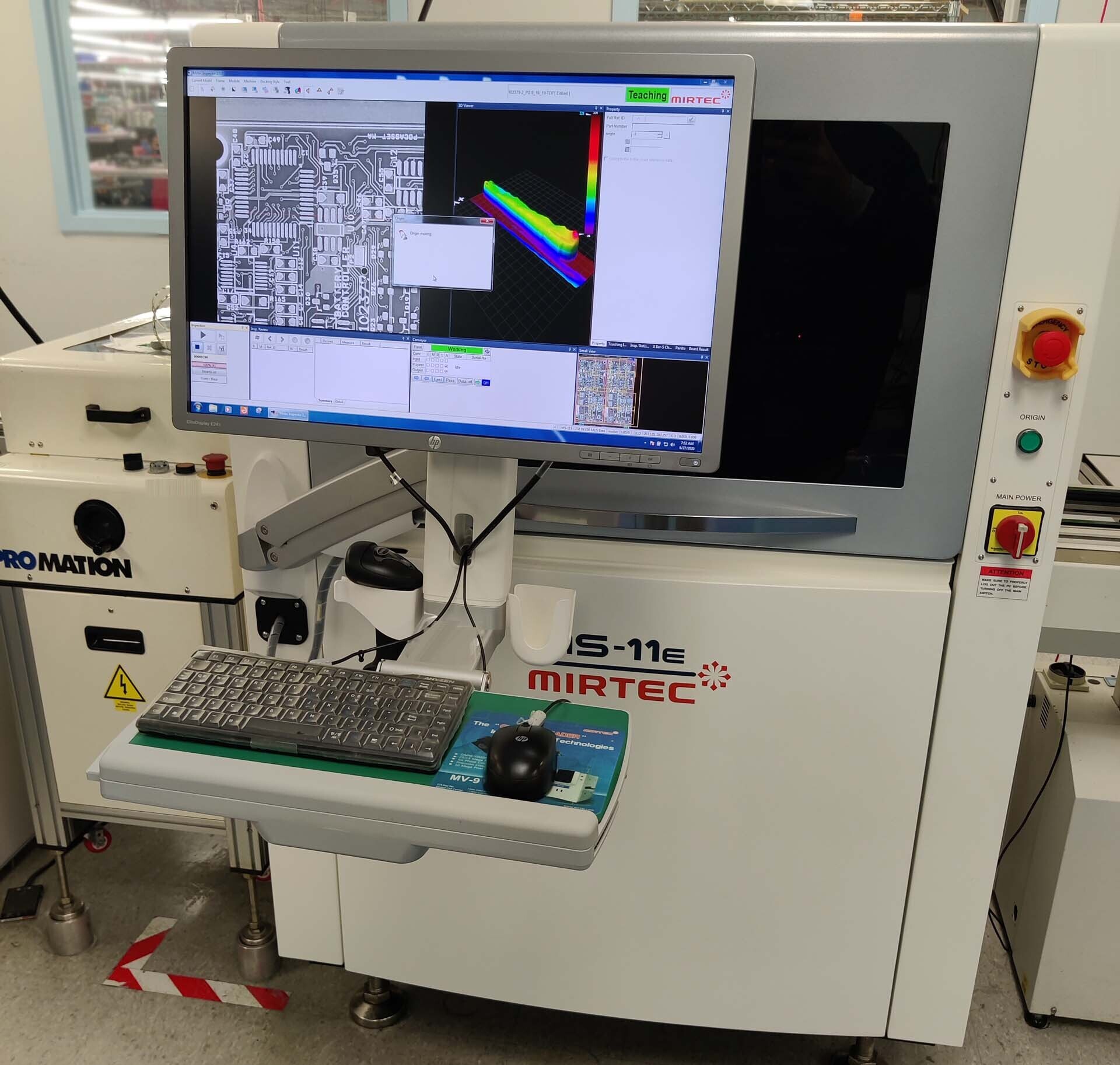

Used MIRTEC MS-11E #9302319 for sale

URL successfully copied!

Tap to zoom

ID: 9302319

Vintage: 2015

Solder Paste Inspection (SPI) system

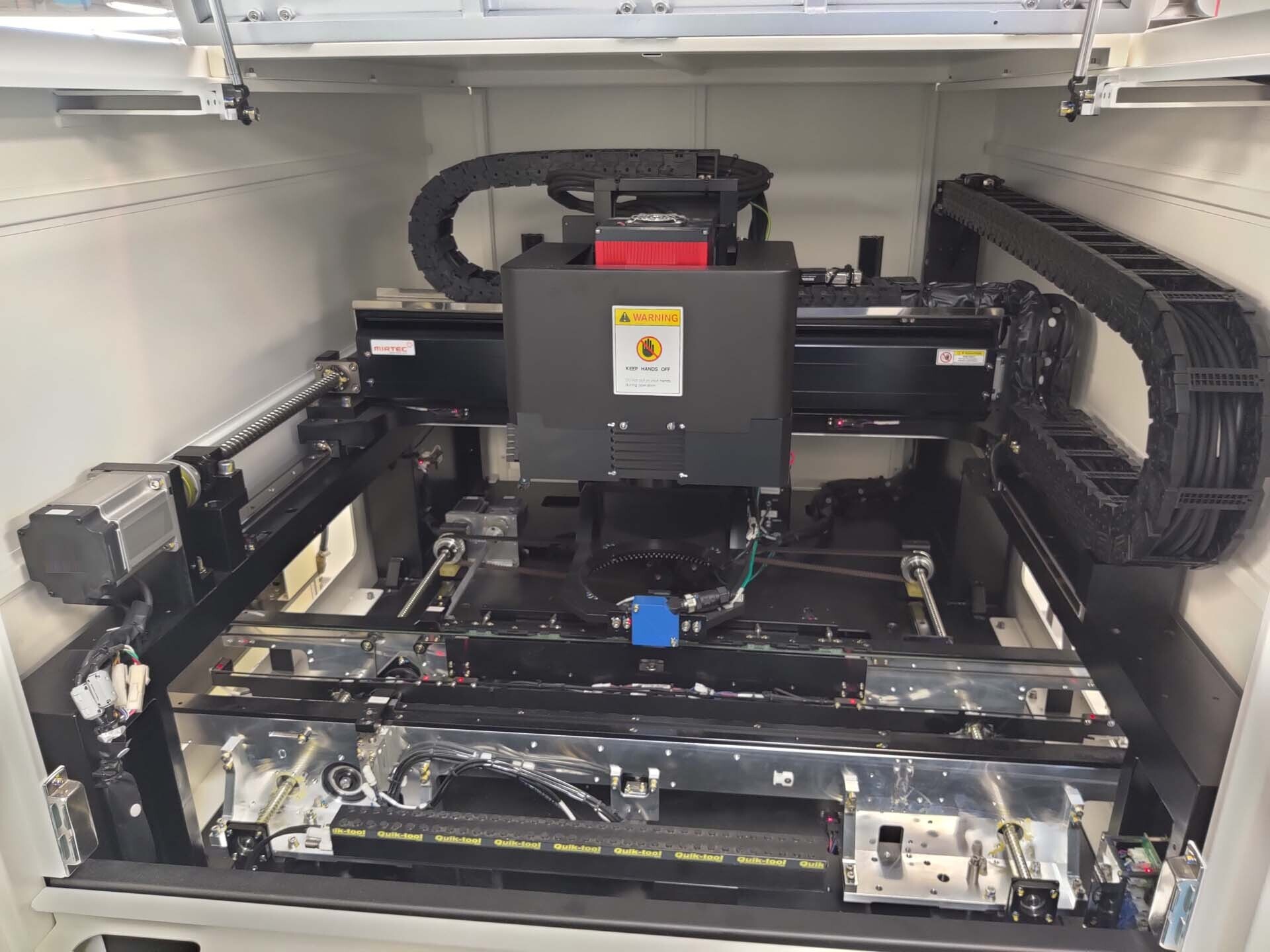

Lens configuration: PRECISION Telecentric compound lens design

Laser PCB warpage compensation: 1µm / Point

PCB Top side clearance: 25 mm

PCB Bottom side clearance: 25 mm (Option: 50.8 mm)

Maximum PCB warpage: ± 3 mm

Barcode reader: 1D / 2D PCB Barcode reading capability

Camera type (Option): Top-down camera

Robot positioning system:

X/Y-Axis: PRECISION Closed loop AC SERVO Drive motor system

Resolution: 1 µm

Repeatability: ± 10 µm

Power requirements: Single Phase, 200-240 V, 50-60 Hz, 1.1 kW

Air requirements: 5 Kgf / cm2 (0.5 Mpa), (71 PSI)

Image Transfer Technology:

15 Mega pixel camera: 3904 x 3904 Pixels

CoaXPress: 120fps

4 Mega pixel camera: 2048 x 2048 Pixels

Camera link: 180fps

Vision system (FOV Size):

15 Mega pixel camera: 3904 x 3904 Pixels

Option 1: Pixel resolution: 20µm

Option 2: Pixel resolution: 15µm

Option 3: Pixel resolution: 10µm

4 Mega pixel camera: 2048 x 2048 Pixels

Option 1: Pixel resolution: 15.71µm

Option 2: Pixel resolution: 11.78µm

Maximum inspection speed:

15 Mega pixel camera: 508ms/FOV

Option 1: Pixel resolution: 20µm

Option 2: Pixel resolution: 15µm

Option 3: Pixel resolution: 10µm

4 Mega pixel camera: 387ms/FOV

Option 1: Pixel resolution: 15.71µm

Option 2: Pixel resolution: 11.78µm

(4) HP CD

Inspector

(2) Conveyor belts

Inspector: 2520 mm

Gray card

Tension monitor mount: 24 mm

Fuse:

Glass tube: 2A

(3) Glass tubes: 5A

Glass tube: 10A

(2) 14 Pin SMEMA communication cables

Manual:

User

Maintenance

2015 vintage.

MIRTEC MS-11E is a cutting-edge PC board assembly and manufacturing equipment for businesses in need of a reliable automated solution that can drastically reduce labor costs while still achieving a high-level of production accuracy and reliability. This state-of-the-art system is designed to meet high-volume production requirements in a wide range of sectors. MS-11E provides a comprehensive solution for PCB assembly that includes Automatic Optical Inspection (AOI), Wave Soldering, Selective Soldering, and reflow ovens. It also has several advanced features, including automatic component pre-positioning and placement, align coordinate customer placement (ACCP) and solder paste printing systems. The unit operates with speed, accuracy, and precision, providing results that can easily exceed customer requirements. MIRTEC advanced technology also includes the MSU-1100 processor, a feature-rich control machine with a large memory capacity. The controller is responsible for all machine movements and communication with peripheral devices. This ensures implementation of programming instructions and efficient data processing. The control tool also includes features to ensure that the manufacturing process runs smoothly, including a self-diagnosis feature to detect any irregularities during the production cycle. MIRTEC MS-11E is also capable of handling a wide variety of PCB components, including 0402, 0603, 0805, 1206, and larger 12X12 components. The asset is able to handle through-hole components, as well as surface-mount and flip-chip components. It is also capable of handling a wide range of finishings and surface mount processes, including solder mask, resist coating, trace drawing, and stencil printing. MS-11E is designed to provide user-friendly operation and is capable of full integration with global components databases such as Component Library Exchange (CLE). With its high-quality design features, MIRTEC MS-11E provides unmatched quality and reliability in a PC board assembly and manufacturing model. By providing comprehensive solutions for PCB assembly applications, MIRTEC PC board assembly and manufacturing equipment can help to significantly reduce time and cost for businesses that require a high-volume production system.

There are no reviews yet