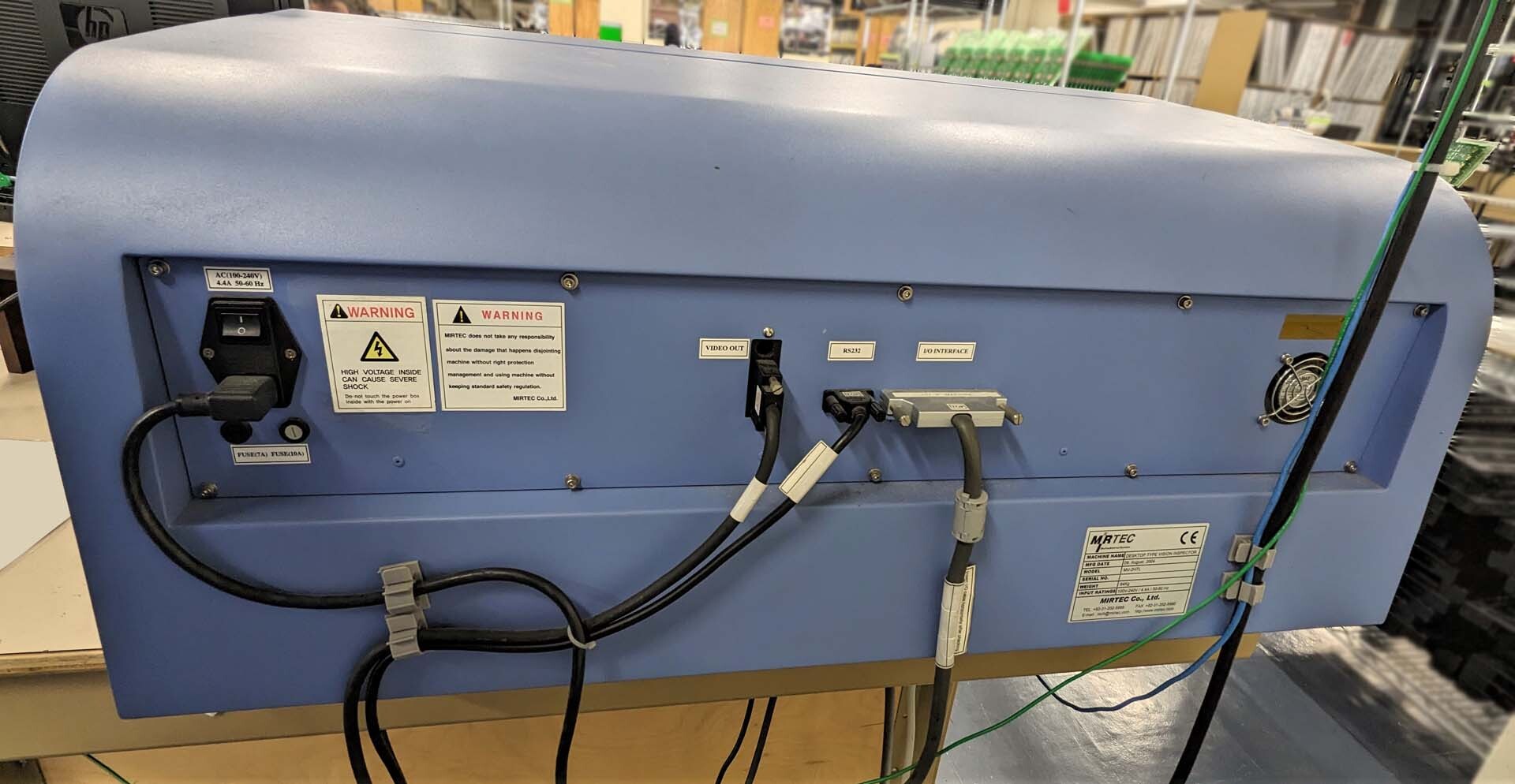

Used MIRTEC MV-2HTL #293656636 for sale

URL successfully copied!

Tap to zoom

ID: 293656636

Vintage: 2004

Desktop Automatic Optical Inspection (AOI) system

DELL GX 270 PC

Monitor

Operating system: Windows XP Pro

2004 vintage.

MIRTEC MV-2HTL is a high speed PC Board Assembly and Manufacturing Equipment designed for medium to high-volume production involving a mix of components and devices with a focus on 0201, 01005 and μBGA/CSP/QFNs components. It boasts a high-speed mounting speed of up to 4,200 CPH, due to its dual placement head of 6 nozzles, which can simultaneously pick and place components in a single operation. MIRTEC MV 2 HTL is equipped with various vision capabilities such as an RGB LED background, four CCD cameras and inspections from all sides for extreme accuracy and reliability. It is also equipped with a high-speed Gantry system capable of repeatably taking images and placing accurately at up to 5G acceleration/deceleration. Furthermore, it features a unique high resolution Multi-axis Linear Scale for maximum placement accuracy and repeatability. MV-2 HTL is equipped with a high efficiency 16" feeder bank with the ability to hold up to 208 Tape Feeders or 128 Stick Feeders. It also has the ability to integrate a number of devices on to the machine, such as a Laser Marking module, Visible/NIR Vision Sensor, Board Clamps and XYR Robot. MIRTEC MV-2 HTL has superior PC Board handling capability and offers the ability to support boards ranging from 50 x 50mm to 510 x 510mm in size. MV-2HTL also has advanced features for screen printing, such as the Jet Printer, which is a high resolution optimised stencil printer that produces consistent results over long run cycles. In addition, it is capable of printing on board components up to 30mm in height and it can also print directly over components. It is capable of printing dots from 50μm to 1mm, and its high-precision adjustment unit allows for fine-tuning of printing parameters. The cleaning capability of MV 2 HTL allows for fast and efficient cleaning of the PC Board before the components are placed. It uses a vacuum nozzle with adjustable suction and a range of cleaning solutions that allow for the effective removal of dirt, dust and flux to ensure that the PC Board assembly is defect free and ready for soldering. MIRTEC MV-2HTL is the ideal machine for medium to high-volume PC Board assembly and manufacturing, with its ultra-high-density component placement capability, advanced vision scrutiny and inspections from all angles combined with its high-speed gantry tool for fast and precise placement and advanced screen-printing capability. It is capable of producing superior quality PC boards to exact customer requirements with repeatable accuracy.

There are no reviews yet