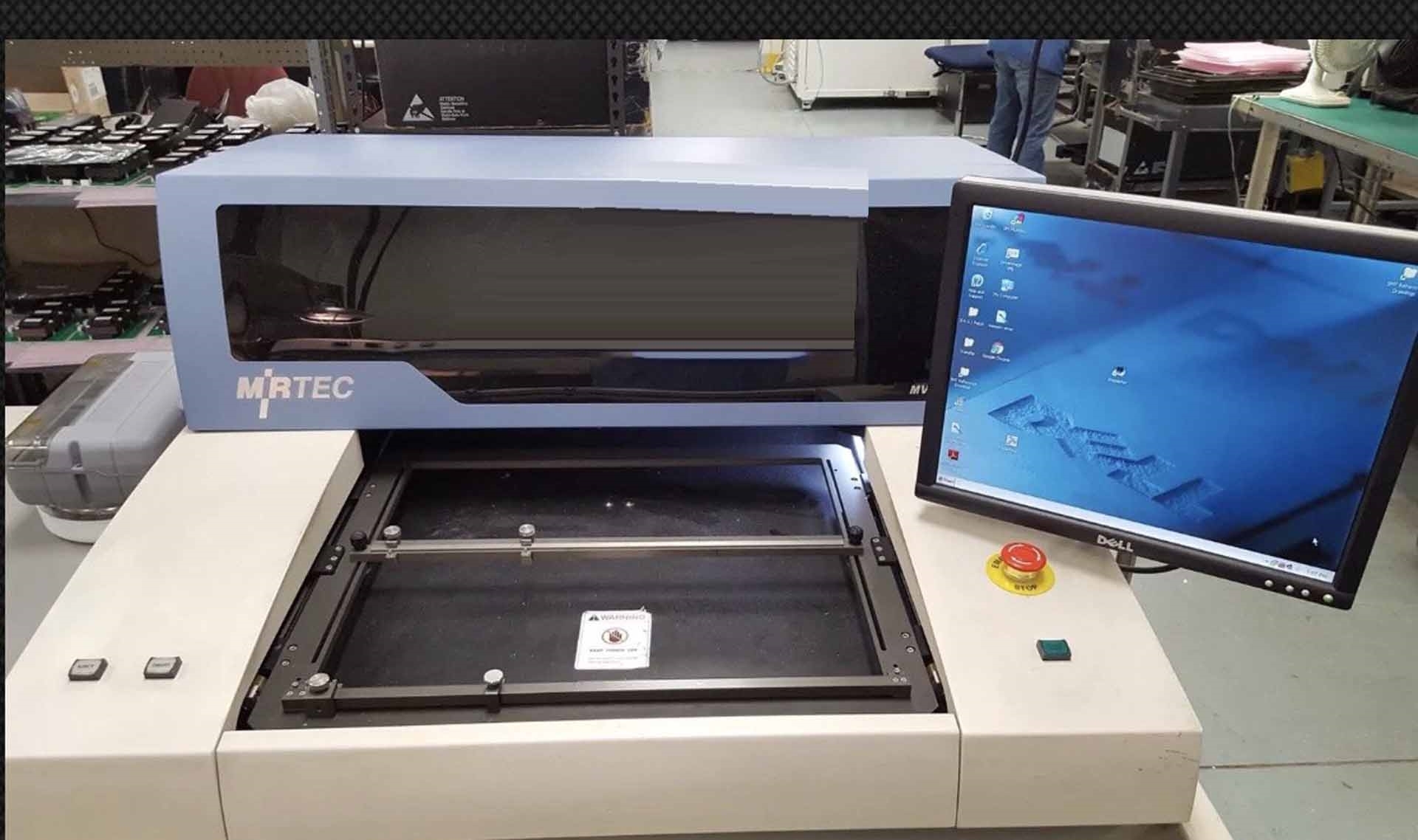

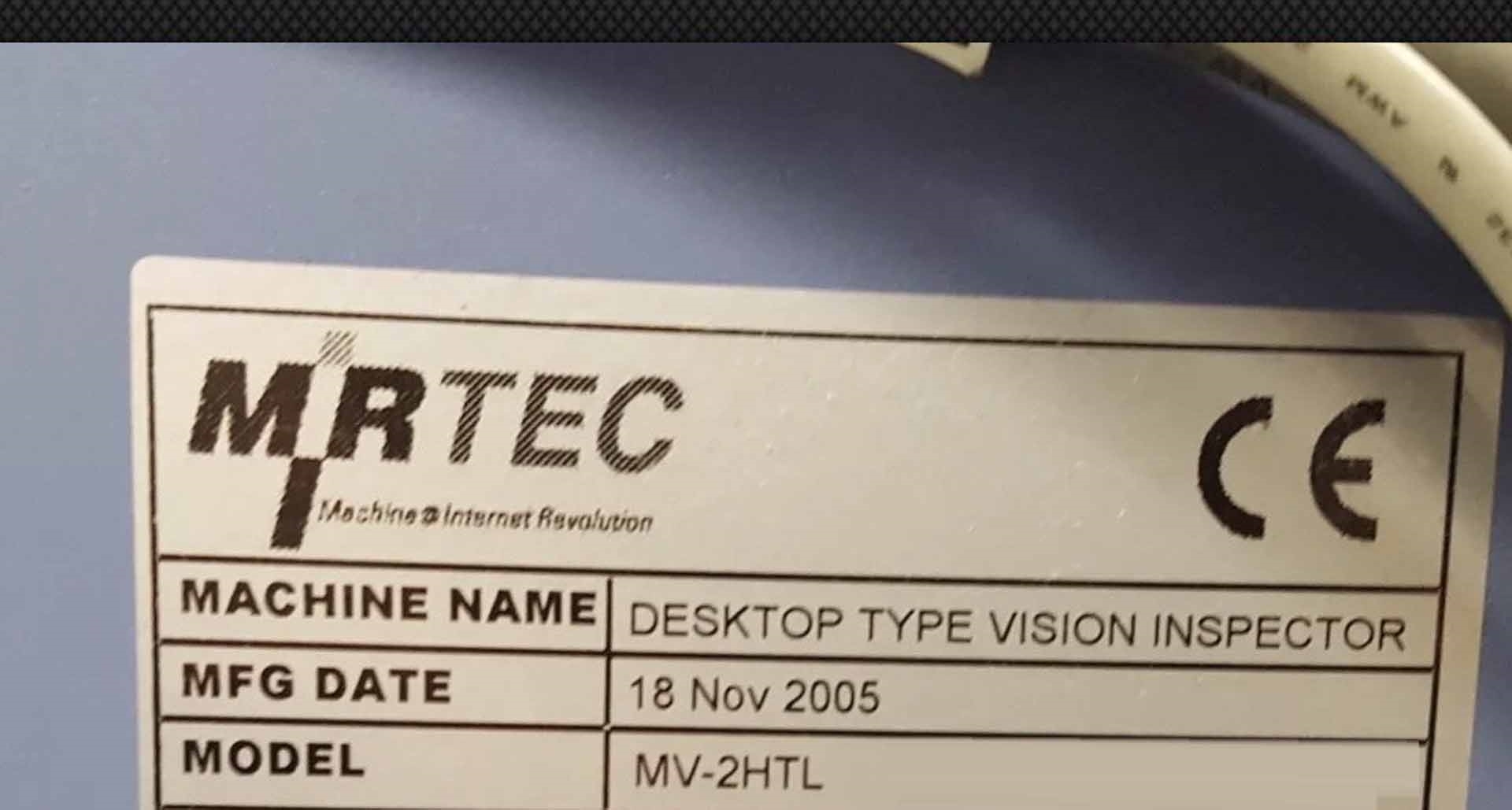

Used MIRTEC MV-2HTL #9208810 for sale

URL successfully copied!

Tap to zoom

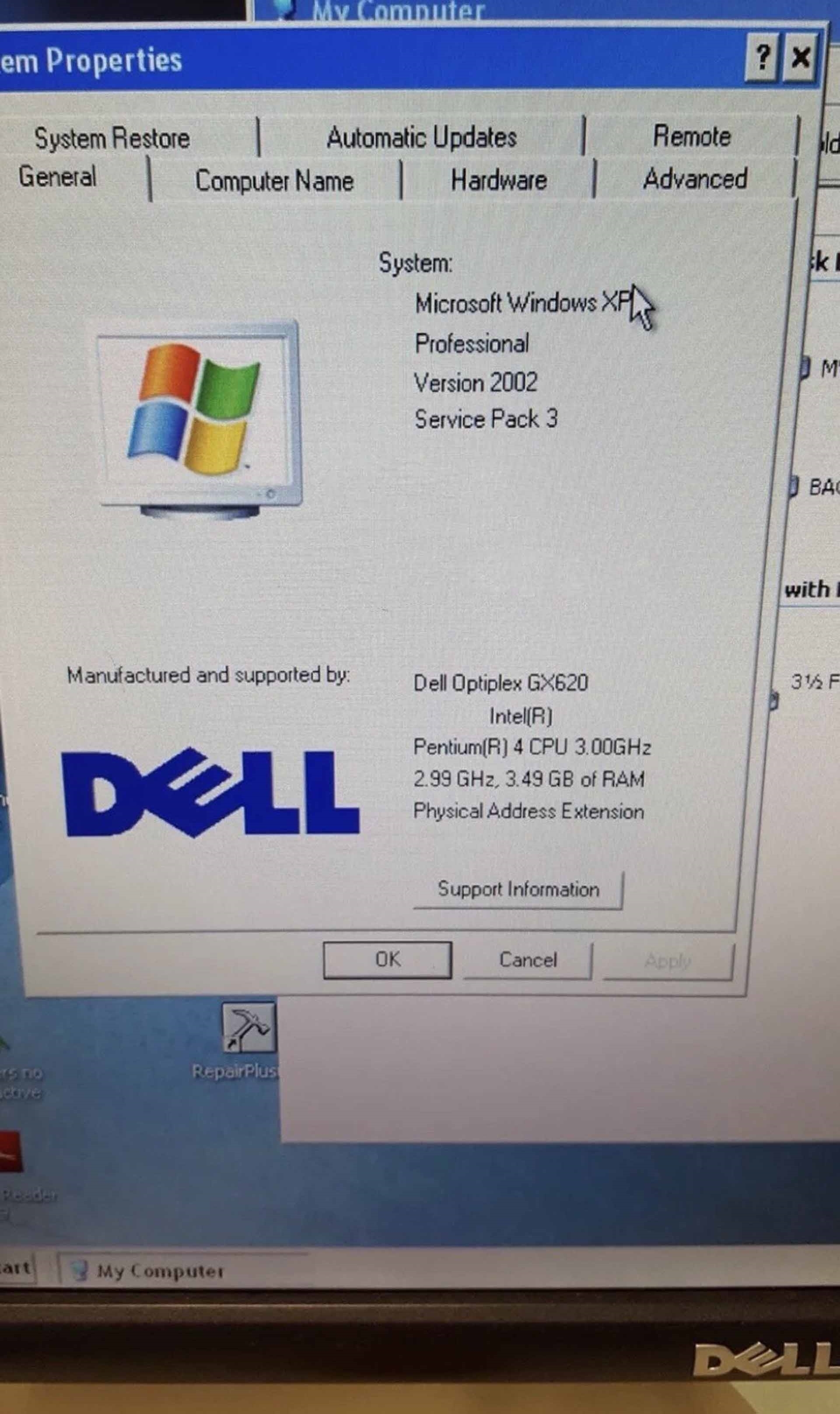

MIRTEC MV-2HTL is a PC board assembly and manufacturing equipment designed to meet the needs of high-volume production. It is an advanced platform offering a number of features designed to increase productivity and reduce cycle times. The system includes an 8-axis pick-and-place module for high speed component placement with an operating speed of 31 PPH. It is capable of handling components with a maximum size of 60x60 mm and a minimum size of 004004 mm. The integrated automaticComponent Recognition Unit (CRS) and camera vision machine ensures accurate placement of components and prevents misalignment. MIRTEC MV 2 HTL has a high-speed Solder Jet fluid window printing tool for fast soldering of leads and pins. It is also equipped with an interactive offline board programming tool that allows users to design templates for efficient production of 1.6 mm thick boards. The asset has high capacity solder-paste dispensing and the paste squeezed out by a high-power compressor valve doctor will be deposited accurately at the locations of the boards according to the programmed pattern. MV-2 HTL also comes with a high-speed microprocessor-controlled detection device that can detect faulty solder joints and other problems after soldering. In addition, the model is capable of post-solder inspection to ensure high quality assembly. It has an advanced built-in conveyor equipment, monitoring system, and LED backlight unit to monitor the production process and detect any faulty components. MV 2 HTL is designed to reduce Turn-Around Time (TAT) and minimize costs associated with manual assembly processes. It can help production lines achieve higher throughputs and better yields while addressing industry standards. It is an ideal solution for high-volume production and offers a suite of advanced features to boost productivity and reduce costs.

There are no reviews yet