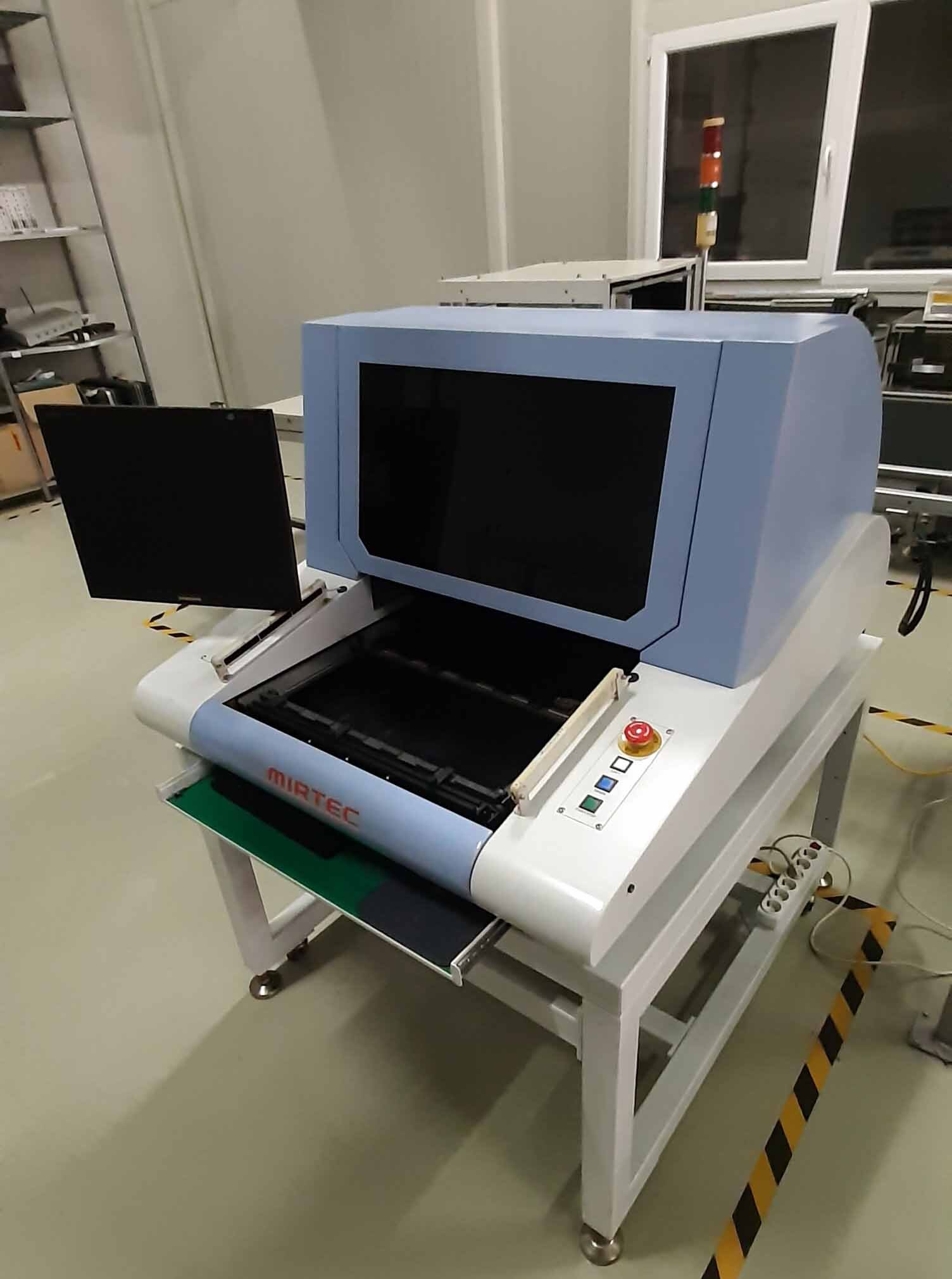

Used MIRTEC MV-3L #293639868 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293639868

Vintage: 2013

2D Automatic Optical Inspection (AOI) system

Maximum PCB:

Normal: 50 mm x 50 mm - 450 mm x 400 mm

With NG Marker: 50 mm x 50 mm - 410 mm x 400 mm

Maximum inspection speed:

10 Megapixel camera:

Type 1 (13.4 μm): 5.293 mm³/sec

Type 2 (9.8 μm): 3.007 mm³/sec

Maximum component inspection:

Type 1 (13.4 μm): 0603 Chip (mm) / 0201 Chip (Inch) / 0.4 Pitch (mm)

Type 2 (9.8 μm): 0402 Chip (mm) / 01005 Chip (Inch) / 0.3 Pitch (mm)

8-Phase coaxial color lighting system

(9) Digital color cameras, 10 MP

Intelli-Beam:

Laser resolution: 8μm / Point

Measurement accuracy: ±20 μm

PCB Top side clearance:

8-Phase coaxial color light: 45mm

PCB Thickness: 0.5 mm- 3 mm

Robot positioning system:

X/Y-Axis: Closed loop stepping motor system

Breaker capacity: 7A

Operating system: Windows XP

PC: Intel i7, 32GB RAM

Hard Disk drive (HDD)

Power supply: Single phase, 100-240 V, 50-60 Hz, 1.1 kW

2013 vintage.

MIRTEC MV-3L is an automated pc board assembly and manufacturing equipment which is used for rapid and reliable surface mount technology assembly, inspection and testing. It is a compact and reliable system based on off-the-shelf components, making it flexible and robust enough to meet any customer's SMT assembly and production requirements. The core of MIRTEC MV 3 L unit consists of a high-speed digital camera and a vision processing board with superior methods of defect detection and classification. The vision processor is capable of printing, reflowing, fluxing, soldering and surface mount device (SMD) placement, while still being able to detect missing components and surface contamination and provide Inspection and Quality results. The vision processor has a sophisticated on-board programming and software machine which provides comprehensive process control and testing capabilities. MV-3L tool has a multi-functional pick-and-place head that can be used for various tasks including solder paste printing, component placement and board repair. The asset also incorporates a closed-loop control model for accurate solder joint formation, which helps to maintain a constant level of soldering quality. The equipment is equipped with an automatic loader and unloader for small and large parts which makes it suitable for even volume production requirements. MV 3 L system has a host of additional features such as parallel programming architecture for faster processing speeds, advanced process monitoring and control features and a comprehensive manufacturing database of SMT components and boards. It comes with a modular and flexible water jet conveying unit which allows quick changeovers and maximum throughput. The machine also has a variety of safety features such as fail-safe switches, key locking and ESD safe areas which ensure the safety of operators and components. In conclusion, MIRTEC MV-3L is an advanced automated pc board assembly and manufacturing tool capable of delivering reliable and high-quality results. The asset offers high-speed and flexible assembly and testing capabilities, making it ideal for high-volume production requirements. It also has various safety features which make it a safe and reliable model for use in manufacturing environments.

There are no reviews yet