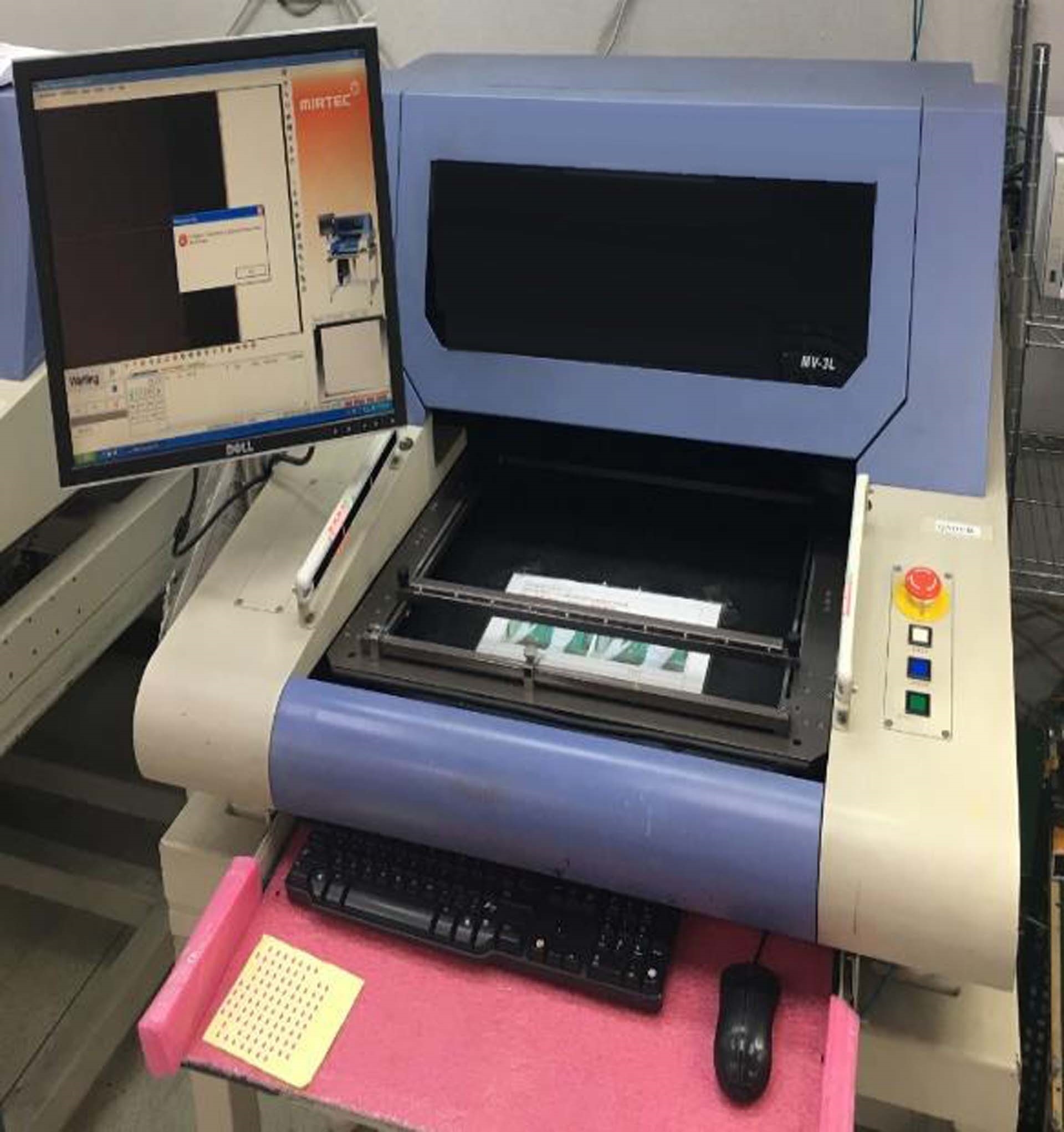

Used MIRTEC MV-3L #9243536 for sale

URL successfully copied!

Tap to zoom

ID: 9243536

Vintage: 2007

Automatic Optical Inspection (AOI) system

PCB Size range: 50 mm x 50 mm to 500 mm x 400 mm

Z-Height measurement accuracy: ±20 um

Resolution: 15 um / Point

Inspection speed: 0.5 Sec / Point

Minimum component inspection: 01005 Chip component

Power: 110-220 VAC ±10%, 50/60 Hz, 5 Amps

2007 vintage.

MIRTEC MV-3L is a PC board assembly and manufacturing equipment designed for high-speed and low-cost production in a wide range of industrial applications. It has advanced optical vision capabilities, which enable the detection of components and defects with accuracy at high speeds, as well as reliable soldering. It uses a two-head soldering system to ensure high-speed and accurate welding of even the most challenging components. The unique dual-track architecture of the unit can be used to provide both high-speed performance and reliable quality output. Additionally, the modular design of the machine allows for the integration of a variety of add-on components to customize the tool to the specific user's needs. MIRTEC MV 3 L is equipped with a high-resolution camera asset, utilizing advanced video processor and image recognition technology for defect detection, allowing for a great level of accuracy and precision. It also has a powerful machine controller to quickly and accurately process the instructions given. It additionally includes a range of additional accessories such as a nozzle cleaning model and a spacer tool to help maintain precise component spacing. In addition, it incorporates an intelligent preheat management equipment to ensure reliable component bonding and solder joint formation. The system is also equipped with a data capture unit which includes a programmable counter and statistic data acquisition. This data can be used to analyze and evaluate defects in order to improve overall yield and reliability. Furthermore, MIRTEC software suite makes it simple to create and edit program parameters and SMT recipes, as well as detailed monitoring and analysis of production, thus ensuring clear, traceable records for validation and compliance. To top it off, the machine also features a user-friendly, intuitive interface which makes it easy for operators to create and manage their programs. It also includes an easy-to-use teaching interface to ensure hassle-free operation and to improve first pass yield. In summary, MV-3L is an PC board assembly and manufacturing tool designed for high-speed and low-cost production. It features advanced optical vision capabilities, two-head soldering, an intelligent preheat management asset, a data capture model, a user-friendly interface, and easy-to-use teaching interface. Its high-performance and flexibility make it a great choice for a wide range of industrial applications.

There are no reviews yet