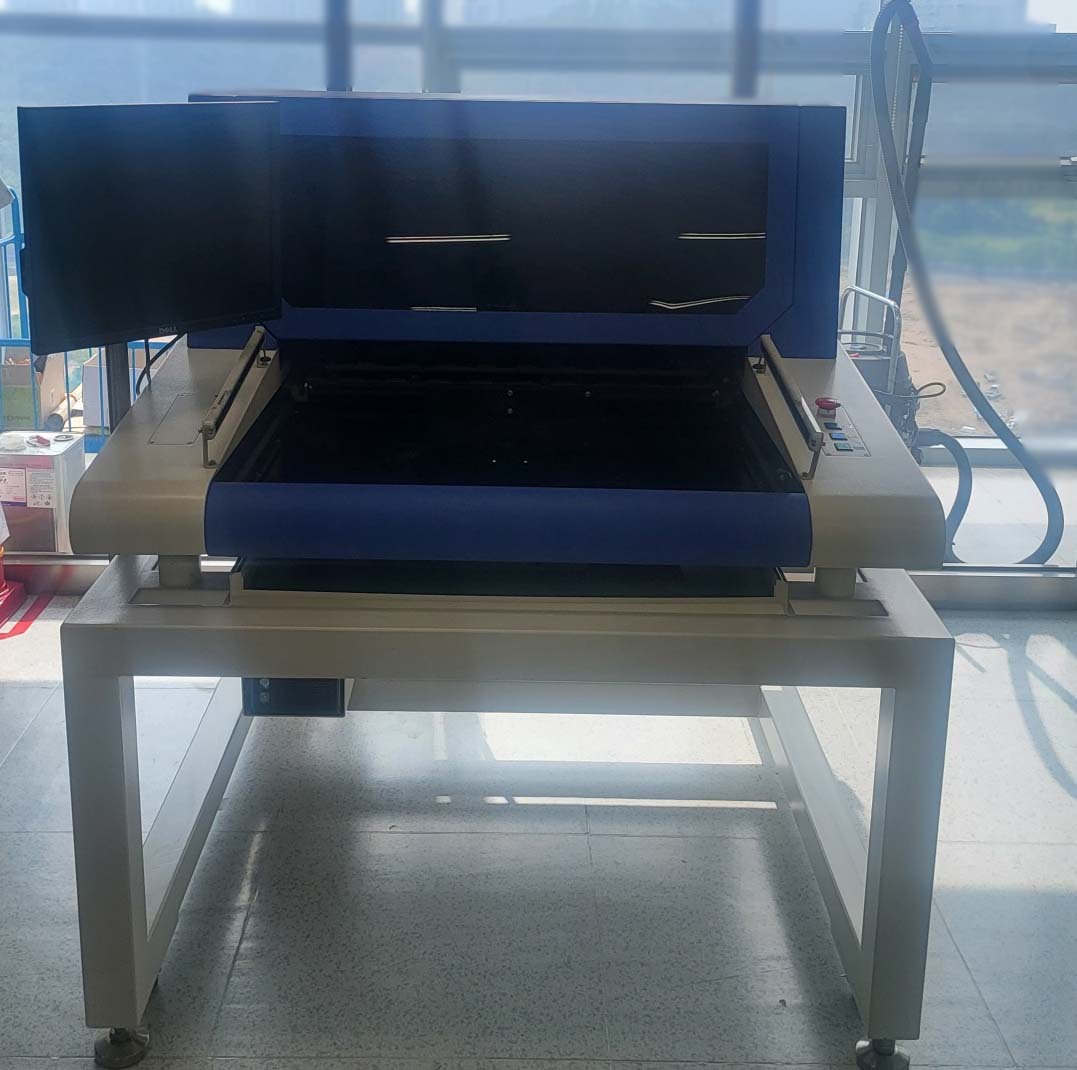

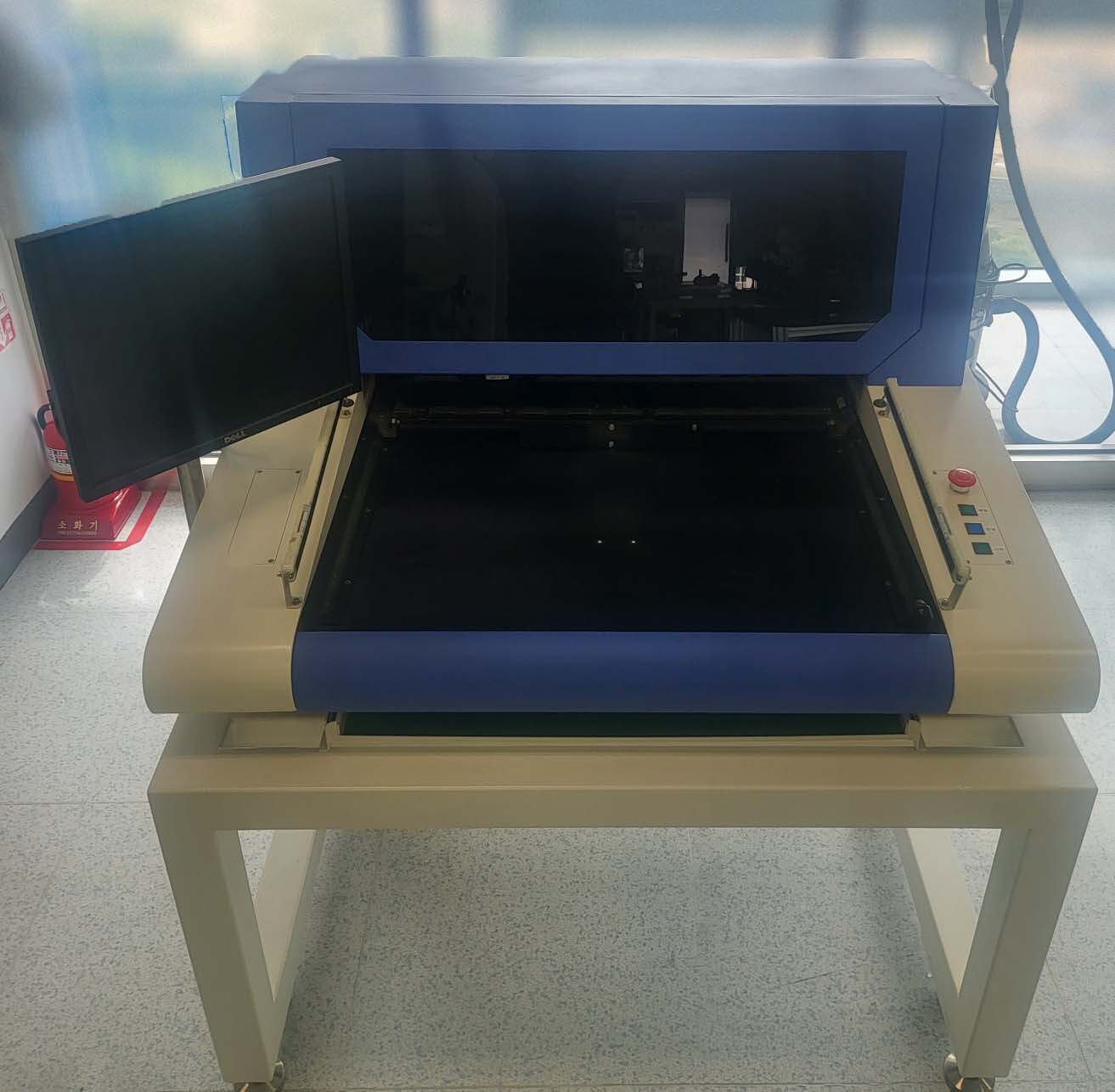

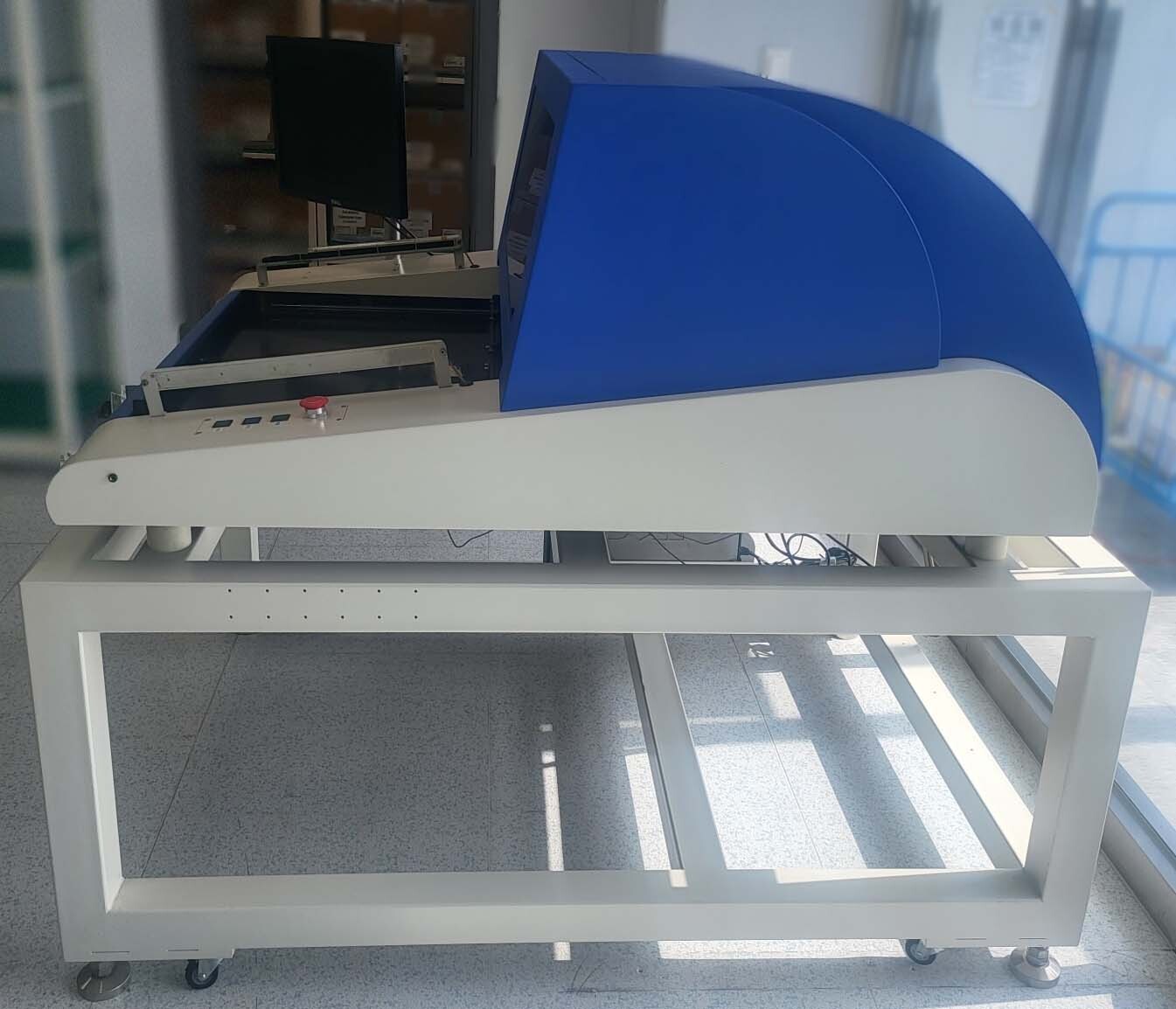

Used MIRTEC MV-3U #293667246 for sale

URL successfully copied!

Tap to zoom

MIRTEC MV-3U is a 3-axis, high-performance, automated pick-and-place machine designed for efficient, effective assembly and manufacturing of printed circuit boards (PCBs). The intelligent multi-vision equipment allows for accurate placement of components of any shape or size, with no manual intervention required. The system is composed of a control unit, conveyer unit, multi-vision optics, automated component placement head, and gripper assembly. The control unit oversees operation of the machine components and features various interactive human-machine interface (HMI) options, allowing for simple, intuitive machine monitoring. Meanwhile, the automatic distributed control machine (DCS) ensures the process is safe and reliable at all times. MV-3U's integrated conveyer tool utilizes an efficient two-way conveyor asset for substrate movement and for component recognition, ensuring effective, accurate component placement. The multi-vision optics equipped in MIRTEC MV-3U provide highly accurate thermal imaging and laser imaging capabilities, allowing it to distinguish components of any size and shape. The adjustable, highly reliable automated component placement head places components with an accuracy of 0.1mm, despite high processing speeds (up to 8000 components/hour). In addition, an up-to-date gripper assembly is also equipped, providing stable, precise gripping of components without damaging delicate parts. In addition to its multi-staged control model, MV-3U also features an integrated un-interrupted power equipment (UPS) ensuring its uninterrupted operation. The machine has been tested in extreme weather conditions and is known to be reliable in both hot and cold environments. With its intuitive design and integrated safety features, MIRTEC MV-3U is the perfect choice for anyone looking for a cost-effective, high-performance PC board assembly and manufacturing system.

There are no reviews yet