Used MIRTEC MV-3U #9199258 for sale

URL successfully copied!

Tap to zoom

ID: 9199258

Vintage: 2010

Desktop Automatic Optical Inspection (AOI) systems

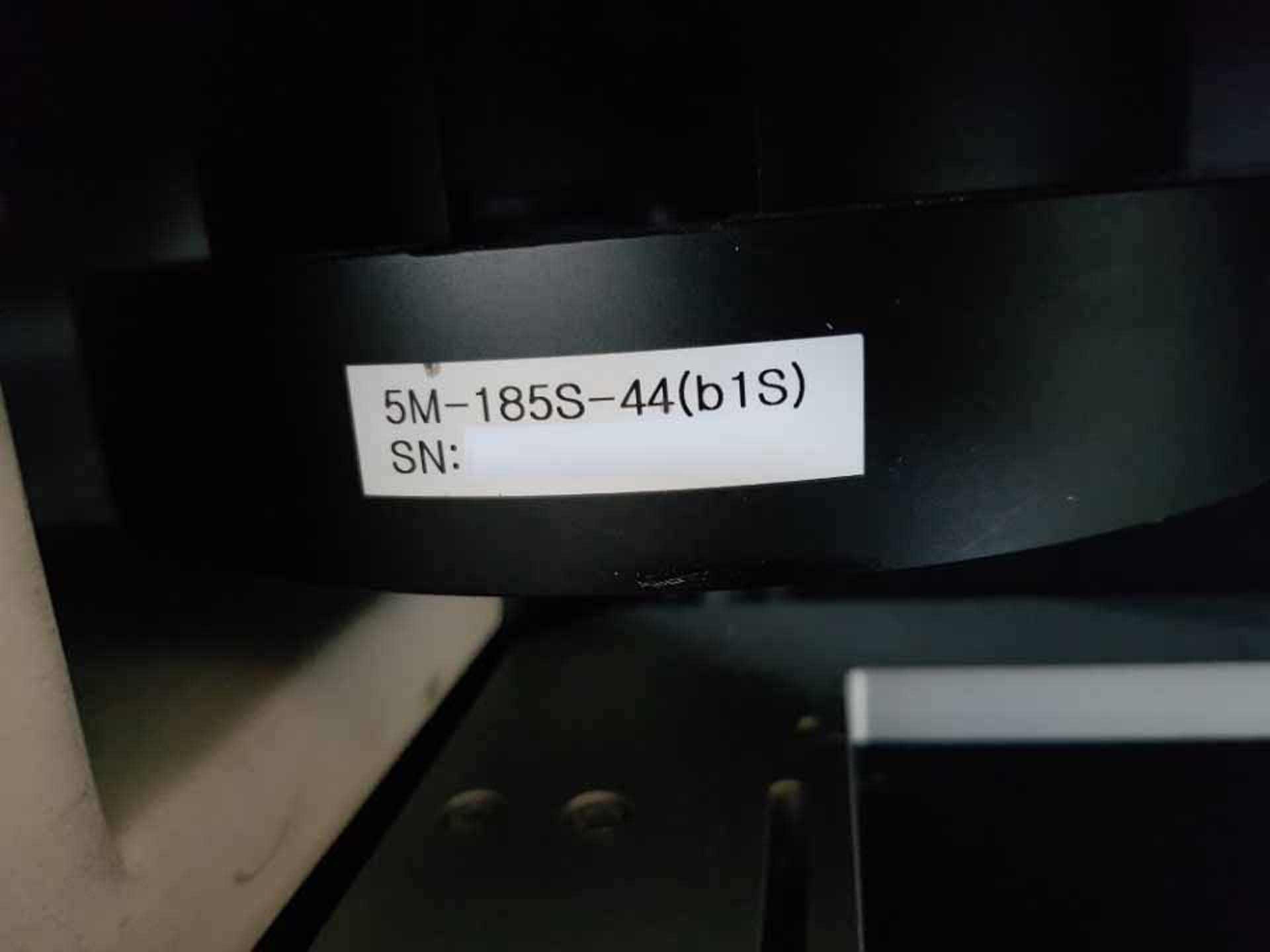

5 Mega pixels

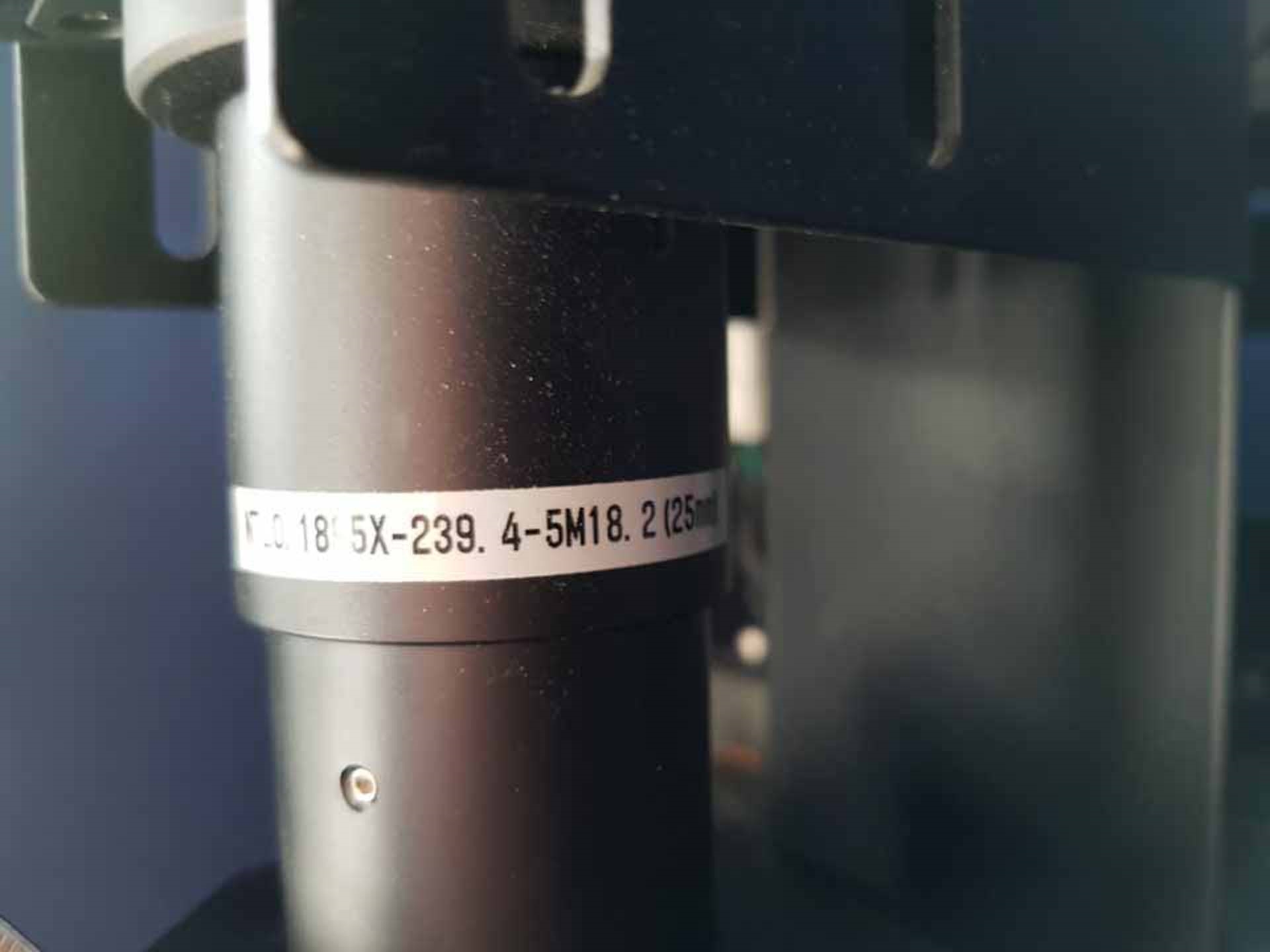

Lens: 8.2

PCB Size: 50 x 50 mm to 660 x 510 mm

2010 vintage.

MIRTEC MV-3U is a high-performance 3-head pick-and-place machine for medium to high-volume production of printed circuit board (PCB) assemblies. Featuring a triple-axis vision equipment, this system provides unequalled solder paste deposition accuracy and component placement accuracy, making it ideal for a wide range of component packages. The robust and precisely designed mechanical components of MV-3U, along with its powerful servomotor driver systems and SMEMA-compliant interconnection, enable the machine to perform highly stable and accurate placement operations. The unit also offers a range of speed settings, high speed component placement and powerful programming with an easy-to-use graphical user interface. MIRTEC MV-3U features a wide working area and can hold boards up to a maximum size of 500mm x 360mm. It also includes a multi-head vision machine for accurate detection of surface mount components. The auto-calibration function, configured for each component type, further enhances the accuracy of component placement. The machine is capable of placing a wide variety of components, ranging from 0201 packages to QFPs, BGA, and both automated and manual placement of components. Its powerful nozzle combination allows for both inline and offline placement, and its advanced feeder technology makes it possible to instantly switch between placements of different sizes. The tool is flexible enough to adapt to components of various sizes.</p> MV-3U also boasts an offline multi-lane asset to facilitate the placement of multi-row components. It uses advanced real-time adjustment algorithms to ensure correct placement direction and quality. The model includes an additional automatic component verification module which uses advanced algorithms to compare the picked component to the CAD library to ensure accurate component placement. MIRTEC MV-3U offers automatic pass-through PCB pathing software to allow the machine to automatically calculate optimal paths for best component placement while avoiding obstacles. The equipment also facilitates the use of lead-free solder processes through its built-in temperature control mode, thereby making this placement system suitable for a wide range of industries. All in all, MV-3U is the perfect pick-and-place machine for high-accuracy, high-speed PCB assembly and manufacturing.

There are no reviews yet