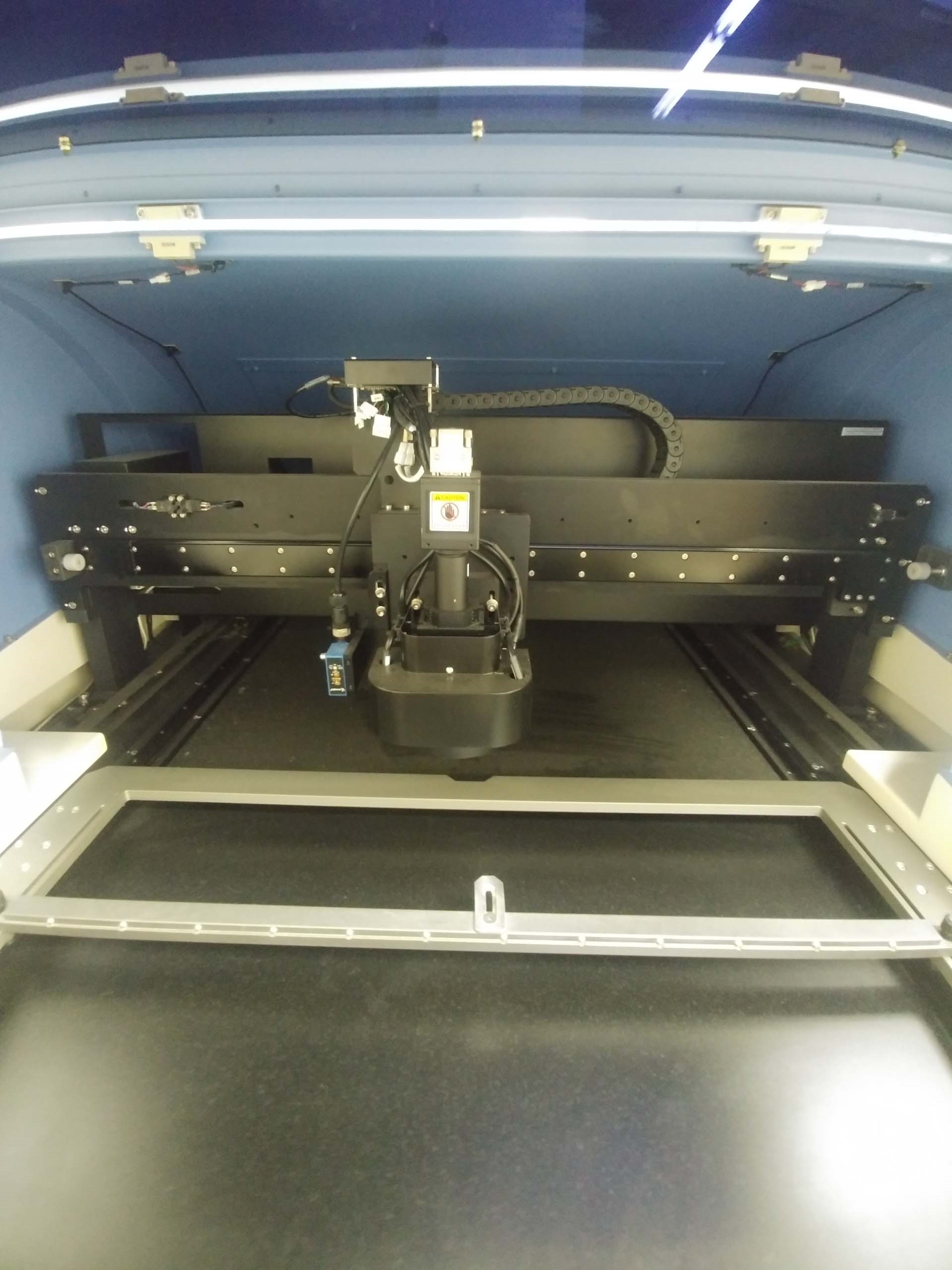

Used MIRTEC MV-3U #9245804 for sale

URL successfully copied!

Tap to zoom

ID: 9245804

Vintage: 2008

Desktop Automatic Optical Inspection (AOI) system

Top camera: 2 MP

Side camera: 2 MP

Camera type: Digital 2

Motion board: ADLINK 8132

Expert digitizer

Coaxial light

Side camera

IPP Library

2008 vintage.

MIRTEC MV-3U is an advanced, high-performance in-line PC Board assembly and manufacturing equipment developed by MIRTEC. The system is designed to meet the needs of SMT, Hybrid Assembly, and Discrete Component Assembly processes. The machine is capable of accommodating PCB sizes up to 12" × 18", making it ideal for higher-volume manufacturability. The unit is equipped with MIRTEC renowned OCR3-VI inspection machine which ensures the accuracy and consistency of PCB assembly processes. The high-resolution cameras offer superior recognition capabilities, making it possible to detect and identify defects even on very small components. The camera control and image processing units provide real-time assessment of PCBs and the surrounding components in order to detect any errors during assembly. MV-3U's dedicated pick-and-place head scanning and nozzle tool depends on a 24-volt motor that is capable of producing high-accuracy placement and speed. The servo-controlled head scans even the slightest offset between components allowing for a smooth, fast calculation of the compensation values for accurate placement of all components. Additionally, the four-head nozzle asset provides a reliable and precise method of placing components on the PCB in compliance with all applicable standards. MIRTEC MV-3U is equipped with a wide range of vision and precision components which ensure the accuracy of each component placement, even for challenging parts. This advanced production model offers a wide range of metering, thru-hole, and thermal components. The nozzle equipment is capable of flexible selection and placement of components for any configuration. The system also features an integrated dragline unit for accurate and repeatable component retrieval. The dragline component storage device efficiently manages the components to ensure that all pickup elements comply with manufacturer's specified feeder machine. Furthermore, the tool is equipped with advanced in-line reflow capabilities for accurate temperature control and precise temperature profiles. Overall, MV-3U is an advanced in-line PC Board assembly and manufacturing asset which is specifically designed for reliability and accuracy. It offers a complete suite of components, including nozzles for placement of components, dragline for retrieval of components, OCR3-VI inspection model, and integrated reflow capabilities. With its large-scale capacity and high precision performance, MIRTEC MV-3U is an ideal solution for high-volume PCBs.

There are no reviews yet