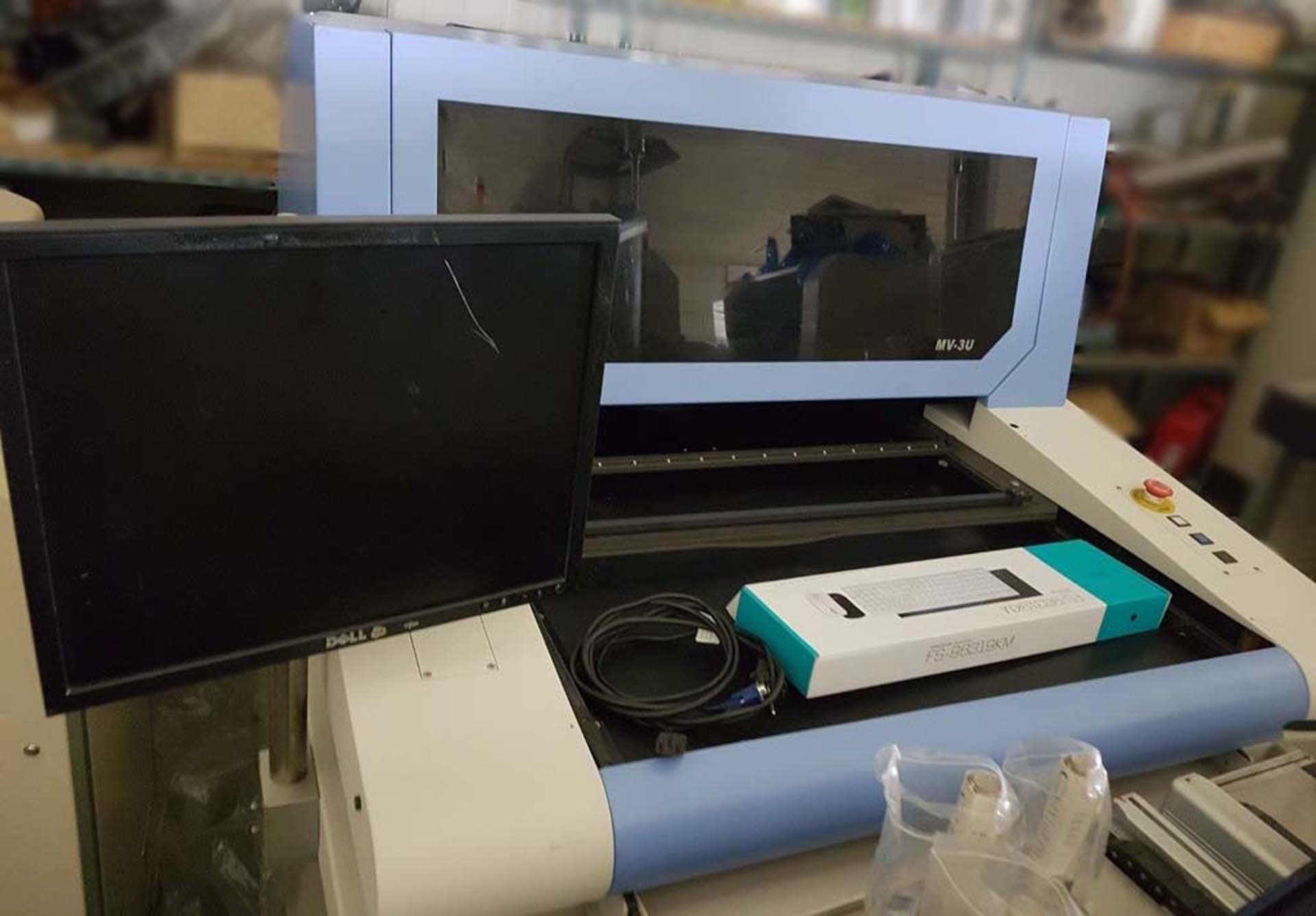

Used MIRTEC MV-3U #9250507 for sale

URL successfully copied!

Tap to zoom

ID: 9250507

Vintage: 2008

Desktop Automatic Optical Inspection (AOI) system

Camera: 2M Pixel

Resolution: 18 µm

2008 vintage.

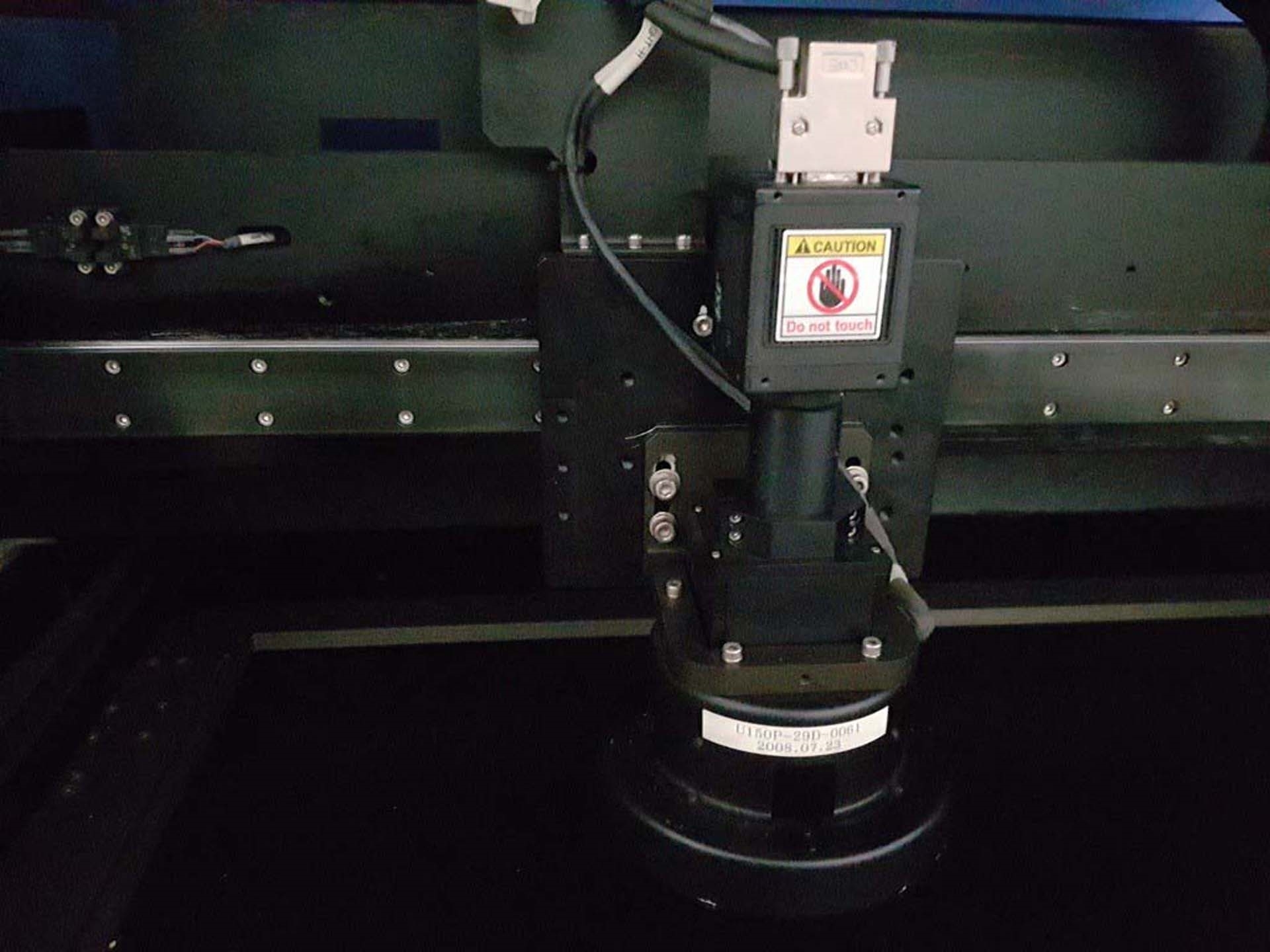

MIRTEC MV-3U is a PC board assembly and manufacturing equipment, which is a comprehensive solution suitable for a wide variety of production processes. It offers an all-in-one solution for various aspects involving PC board assembly, including soldering, programmable optical inspection (POI), and more. This Ultimate-level system is equipped with multiple advanced features to ensure a reliable, cost-effective and efficient production process. MV-3U features a high-speed image processing unit, allowing it to conduct the most precise automation processes at high speeds with minimal errors. Additionally, its motor mechanism provides an increased accuracy in soldering, resulting in faster and improved productivity for any production line. Furthermore, it is equipped with an advanced vision-aided inspection machine that identifies errors and defects at an early stage. To optimize production processes, MIRTEC MV-3U is equipped with a powerful programming software which can be used to create complex programs with ease, while the auto teach function allows programs to be edited quickly. Additionally, the tool simplifies the setup and debugging process, due to its user-friendly graphical interface, and its real-time job tracking helps ensure efficient management of the production process. MV-3U also provides various post-soldering inspection options, such as soldering accuracy testing, solder defect inspection, and more. In this regard, the asset provides a high-resolution camera with a unique color-recognition technology, which helps verify the accuracy of soldering and detect common defects. Similarly, it comes with the optional programmable optical inspection model, allowing users to quickly analyze and identify any defects using a high-resolution equipment that can be configured for an array of product types. In conclusion, MIRTEC MV-3U is an advanced PC board assembly and manufacturing system that offers a robust set of features to ensure reliable, accurate and productive processes. Its high speed image processing, motor mechanism, and user-friendly programming software make it ideal for any production line. Furthermore, its post-soldering inspection capabilities help verify the quality of the production process and minimize potential errors.

There are no reviews yet