Used MIRTEC MV-3U #9265128 for sale

URL successfully copied!

Tap to zoom

ID: 9265128

Vintage: 2010

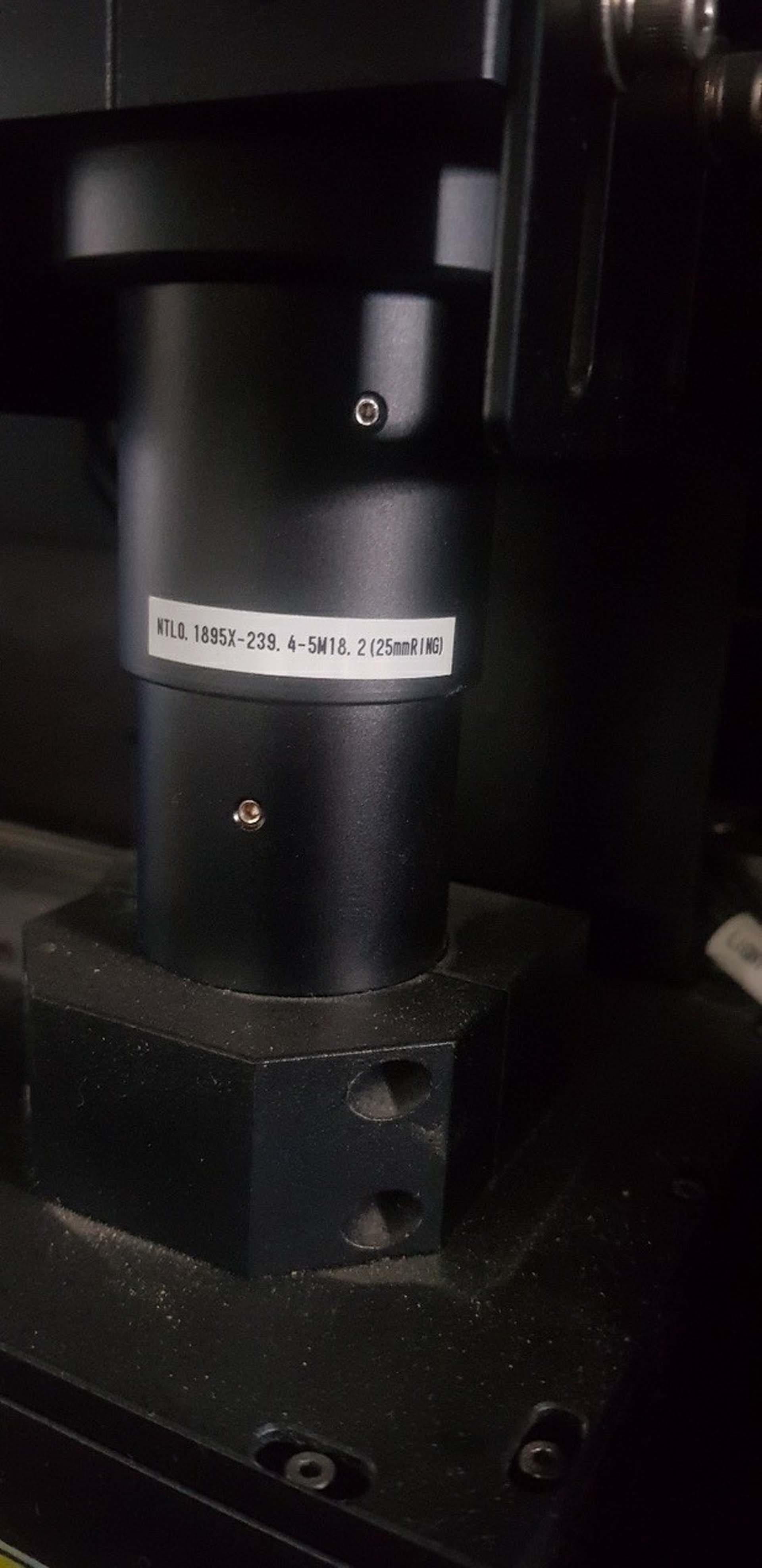

Desktop Automatic Optical Inspection (AOI) system

Camera: 5M

Resolution: 18 µm

2010 vintage.

MIRTEC MV-3U is a state-of-the-art pc board assembly and manufacturing equipment designed to meet the increasing demands of the electronics industry. This latest system features improved transport unit, enhanced component placement accuracy, faster machine throughput, greater cost savings and improved defect detection capabilities. The innovative transport tool utilizes an advanced shuttle asset design to transport PCBs from the input stage to the output stage. It utilizes an ultra-thin Guide Belt Conveyor Model, incorporating sophisticated design principles to achieve better accuracy in board positioning. This ensures that any errors or misalignments during the transport process are prevented. MV-3U employs sophisticated component placement technology, including a dual head retainer for high-speed component manipulation and advanced vision recognition for precise component positioning. It also utilizes a direct image recognition equipment for component identification, in order to minimize placement errors. Moreover, the system features a defect detection unit which can identify discrepancies in component and placement accuracy at high speed. MIRTEC MV-3U features a high throughput of up to 30,000 CPH, enabling users to complete their projects at lower costs and shorter turn-around times. MV-3U also features a comprehensive line of components, from electronic parts to passive placed components, as well as an array of options for advanced SMT processes. It also features an array of software applications designed to enable users to optimize their processes and improve accuracy. MIRTEC MV-3U is also equipped with video-based 2D height measurement and 3D mapping for real-time inspection on the machine. These features help to detect any issues within the board before the soldering process occurs, significantly improving yield. The tool also features a Post-Placement Repair Asset, which enables users to fix discrepancies in components and placement, and reduce production costs. MV-3U is a fully automated, cost-effective solution for pc board assembly and manufacturing. With its cutting-edge technology, users can achieve faster throughput and reduce overall costs, while ensuring the highest level of component placement accuracy and defect detection.

There are no reviews yet