Used MIRTEC MV-6DL #293667009 for sale

URL successfully copied!

Tap to zoom

ID: 293667009

Vintage: 2022

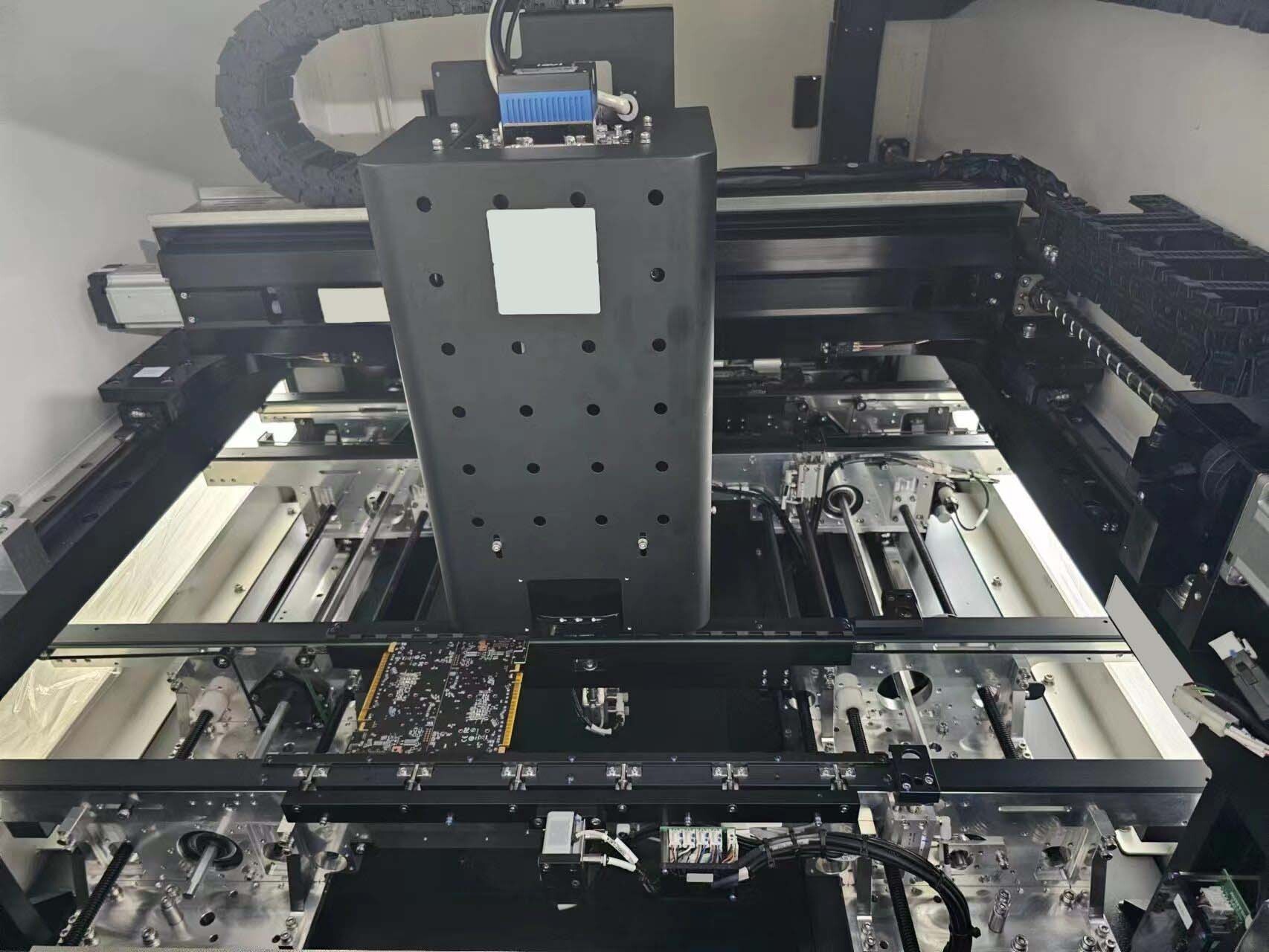

3D Automated Optical Inspection (AOI) system

Speed: 15 μm

Camera: 15 Megapixel

CoaXPress: 4260 mm²/sec

PCB Size: 50 x 50 - 490 x 300 mm (dual rail)

High accuracy: ±3 μm

8-Projection moore technique

2022 vintage.

MIRTEC MV-6DL is a multi-function automatic board assembly and manufacturing equipment that takes components from its onboard feeder and places them onto printed circuit boards (PCBs). It is designed for fast and accurate production, offering a variety of capabilities to meet the demands of most modern PCB assembly requirements. MV-6DL is equipped with four different heads that can be used in accordance with each assembly and manufacturing needs. First is the Motorized Vision Head, which utilizes line scans to quickly and accurately detect board components and their positions. Second is the High-Speed Vision Head, which uses a CCD camera and color/gray-scale image processing to identify posts, wave soldering and fine pitch components. Next is the High-Speed Precision Head, which is capable of component placement with 0.4 mm accuracy by using a nozzle-mounted motorized Z-axis. Finally, the Laser Soldering Head is used for soldering SMD components. MIRTEC MV-6DL also includes a built-in feeder management system, which is able to store up to 32 different components, each with their own feeder. This allows for simultaneous loading on different components. Furthermore, the feeder management unit also includes software for setting up digital Parts Genomes, which automatically adjust feeder settings depending on the components used, increasing accuracy and efficiency. Moreover, the machine offers an integrated Vision Tool, which allows for intelligent recognition of parts and board locations, as well as alignment and verification. This helps ensure the correct location of each component, which is especially important for high-precision tasks. Additionally, the asset features an Optical Centering Model, which is able to detect warped boards and compensate, thus ensuring the accuracy of component placement. In addition to its excellent component placement and assembly capabilities, MV-6DL also includes features that help manage and track production run data. This includes a built-in Personal Computer, which allows operators to monitor production status, set manual adjustments and store data for statistical analysis. This helps operators manage production of complex PCB assemblies with greater overall efficiency. Overall, MIRTEC MV-6DL is an excellent choice for high-precision PCB assembly and manufacturing. With its impressive component placement accuracy, feeder management equipment, integrated Vision System and Optical Centering Unit, the machine is ideal for modern, high-volume PCB assembly tasks.

There are no reviews yet