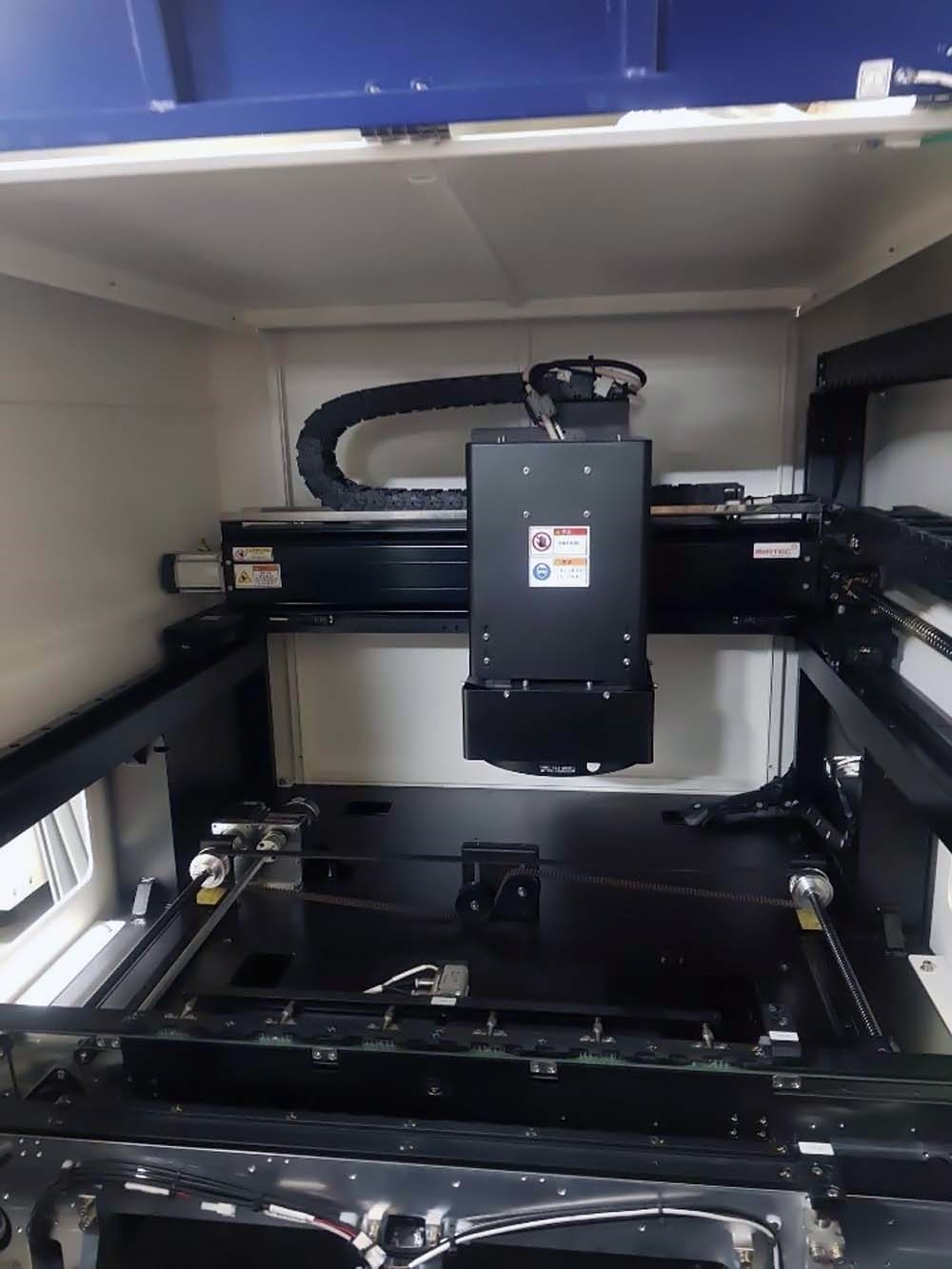

Used MIRTEC MV-6E #9262890 for sale

URL successfully copied!

Tap to zoom

ID: 9262890

Vintage: 2018

Inline Automatic Optical Inspection (AOI) system

With 10M camera

Resolution: 3 um

Maximum PCB size: 510 x 460 mm

Conveyor direction: Left to right / Front rail fixed

SPC Included

Power: 208~240 VAC, Single phase, 50/60 Hz

2018 vintage.

MIRTEC MV-6E is an advanced pc board assembly and manufacturing equipment designed to securely and accurately process complex printed circuit boards with excellent speed and efficiency. It is an industrial-grade system that integrates through-hole and surface-mount technologies into a single platform. With its integrated, multi-axis vision unit, precise alignment and optimized processes at higher speed, it can effectively address complex assembly challenges. MV-6E is equipped with a robust, highly reliable precision motion control machine. It features a material handling station that allows for quick and easy board loading, transfer, and storage. The tool is capable of accommodating multiple board sizes and densities, with its user-friendly software suite. This makes it easy to customize the assembly process to meet customer needs. It enables cost-efficient, high-speed integration of various production processes, from design to delivery. MIRTEC MV-6E also features a multi-axis vision asset that provides 3D data scans of the PCBs and can detect component position, create inspection masks, and detect imperfections. This powerful vision model ensures near-perfect assembly accuracy. Additionally, the unit is equipped with sensitive fault detection, prevention, and correction functions, allowing the user to be alerted to problems before they become unrepairable and result in a costly failure. This, along with its easy-to-use software suite, ensures a steady stream of quality output at higher speeds. MV-6E has a maximum IC Pitch of 0.5mm, 10.0mm for height, and a minimum component size of 0201 for components. It is also capable of operating at a range of heights, from 1.2" to 7.2", and is able to dispense glue with a repeatability of +0.01mm. It can securely handle boards up to 4mm in thickness and works at a maximum speed of 40,000 cph. Its flexible programming allows for up to 1000 unique placement programs and 100 component types, with a wide variety of component formats, including SOIC, QFP, PLCC, SOP, and BGA. Overall, MIRTEC MV-6E pc board assembly and manufacturing equipment is a powerful, cost-effective system that helps expedite complex assemblies with excellent accuracy and resolution. It comes with a multitude of features, such as multi-axis vision unit, robust motion control, sensitive fault detection, and user-friendly software suite, each designed to ensure a steady output of quality parts.

There are no reviews yet