Used MIRTEC MV-9 #293617834 for sale

URL successfully copied!

Tap to zoom

ID: 293617834

Vintage: 2014

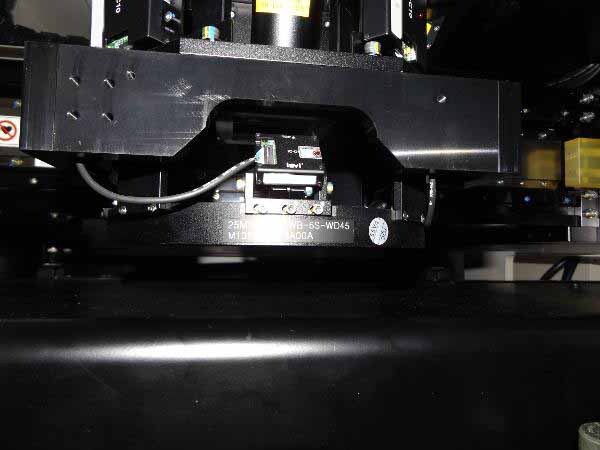

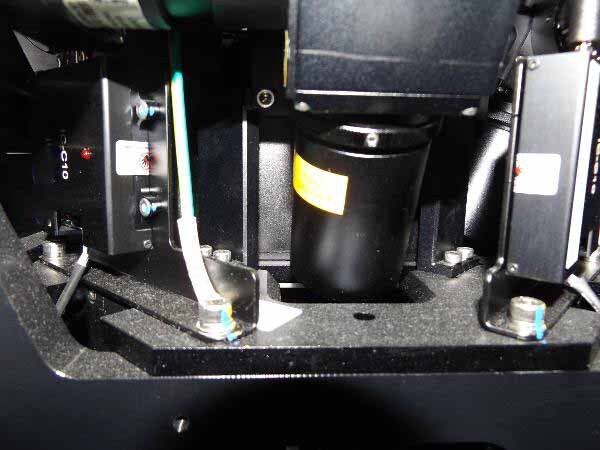

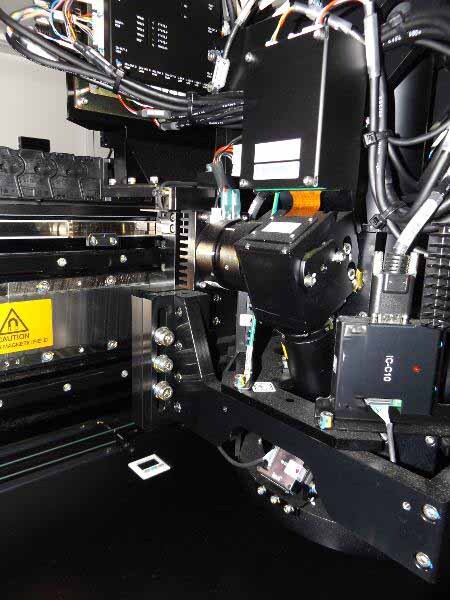

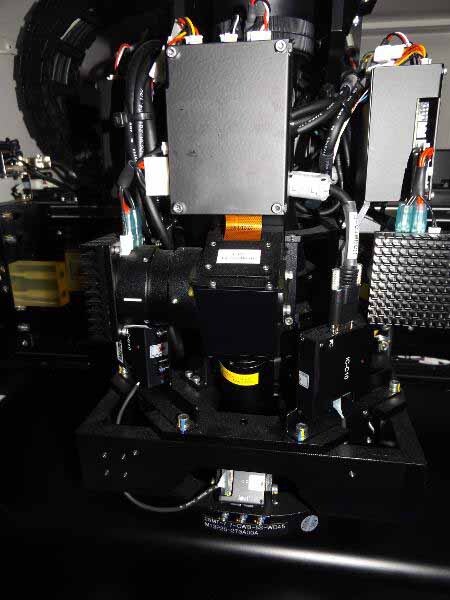

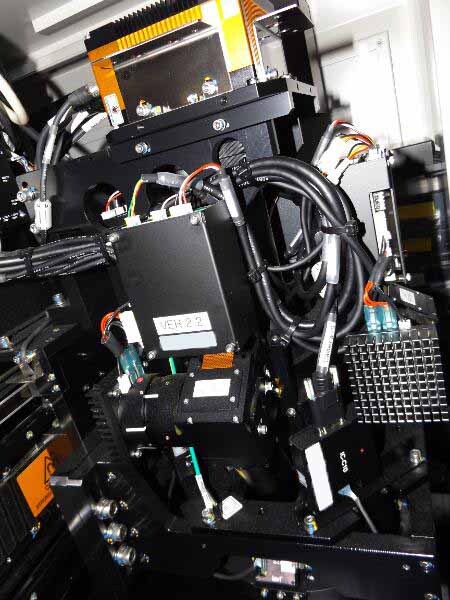

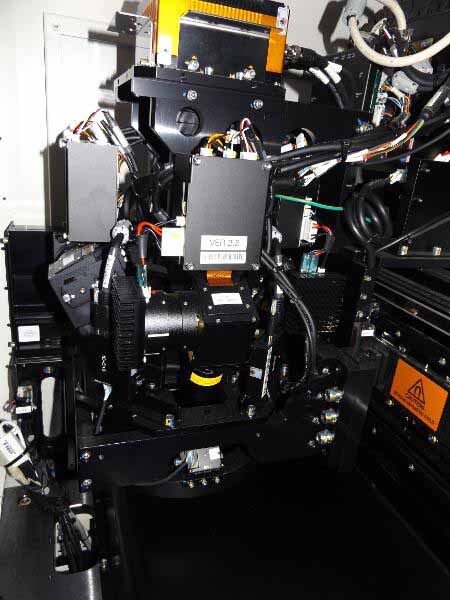

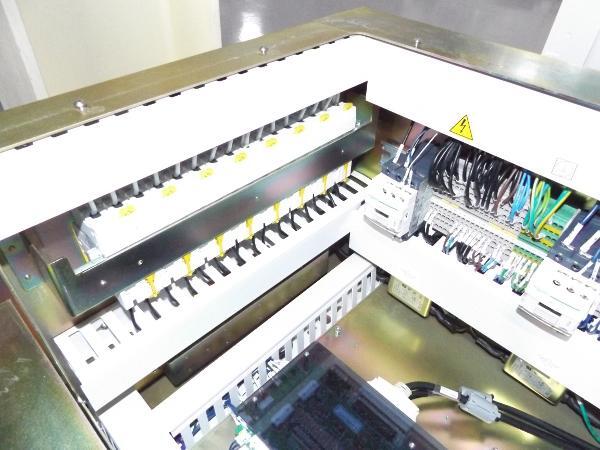

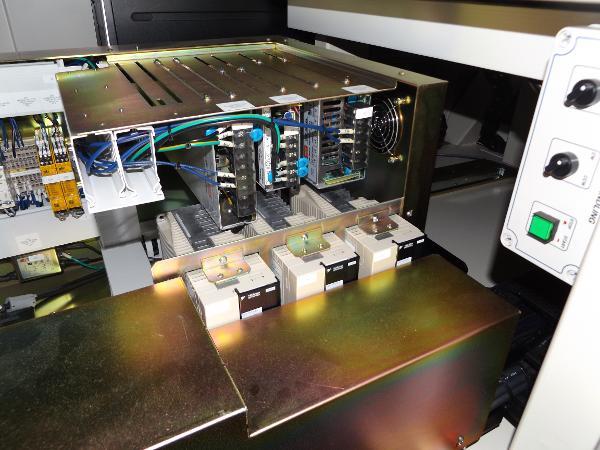

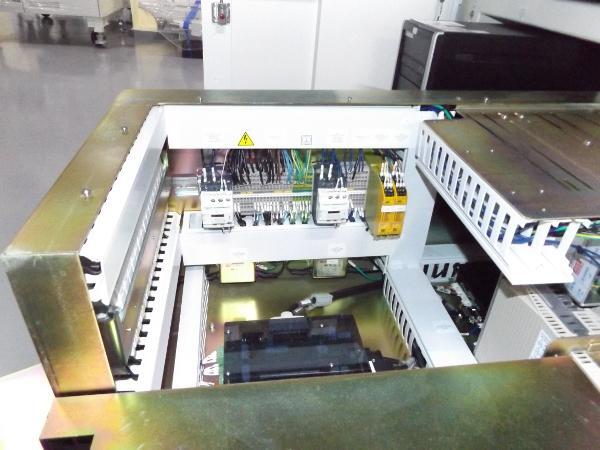

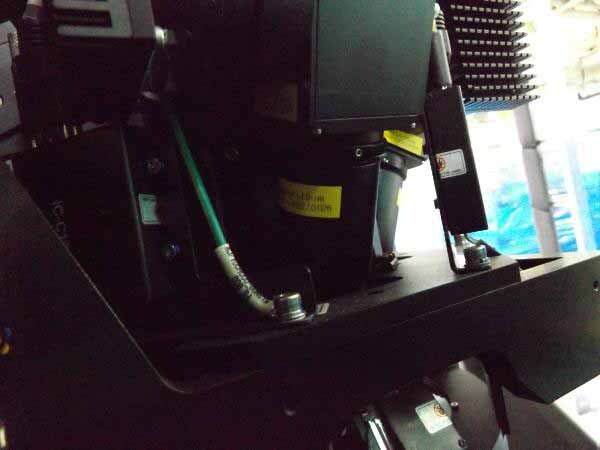

3D In-line Automatic Optical Inspection (AOI) system

2014 vintage.

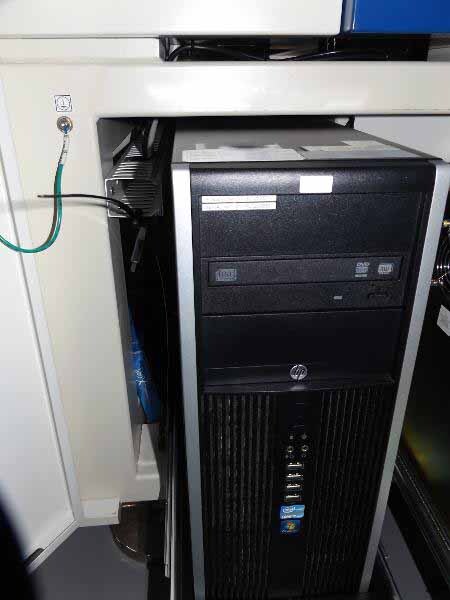

MIRTEC MV-9 is an automated board assembly and manufacturing equipment designed to provide accurate, high-speed creation of printed circuit boards (PCBs). This advanced system utilizes advanced optical recognition technology and high-speed programs to accurately place SMT components onto the PCB. The result is unrivaled accuracy and repeatability for both prototyping and low-volume production. MV-9 features an intuitive, user-friendly interface for easy setup and operation. To start, users choose from a variety of software packages to create job specs that define their desired part design. The specs can be easily adjusted for different board configuration, component type, and other parameters. The unit then processes this data to determine the placement coordinates for each component. Once prepared, MIRTEC MV-9 is capable of handling boards from 0.2mm to 12.7mm thick and up to 820 mm long with an X-Y movement accuracy of 0.02mm. It also boasts a delivery speed of up to 30,000 CPH (components per hour) with a placement accuracy of +/- 0.02mm. The machine can handle a variety of body sizes and different component shapes, including tubes, cubes, and other irregularly shaped components. The tool also comes with a variety of other features. It can handle solder paste deposition, component placement, and component verification. The component verification feature helps to ensure that each component has been accurately placed. The asset also features a fully integrated feeder model that helps to save time and reduce re-loading and component waste. MV-9 can also work with a variety of component placement methods, including pick-and-place and direct-placement. The equipment can also be adapted to take advantage of various nozzle profiles and placement techniques to ensure that each component is placed accurately. The system also allows for real-time monitoring and machine control. Finally, MIRTEC MV-9 comes with an embedded machine vision unit. This machine features advanced imaging techniques and powerful algorithms for defect detection and correction. It also supports user-defined component profile configurations, allowing users to customize their component profiles according to their desired requirements. MV-9 is designed to provide users with unparalleled accuracy and repeatability in their PCB design and manufacturing jobs. By utilizing advanced optical recognition technology and high-speed programs, the tool ensures accurate component placement and component identification. With its intuitive user-interface, advanced machine vision asset, and integration with a variety of component placement methods, MIRTEC MV-9 is an excellent choice for any PCB manufacturing environment.

There are no reviews yet