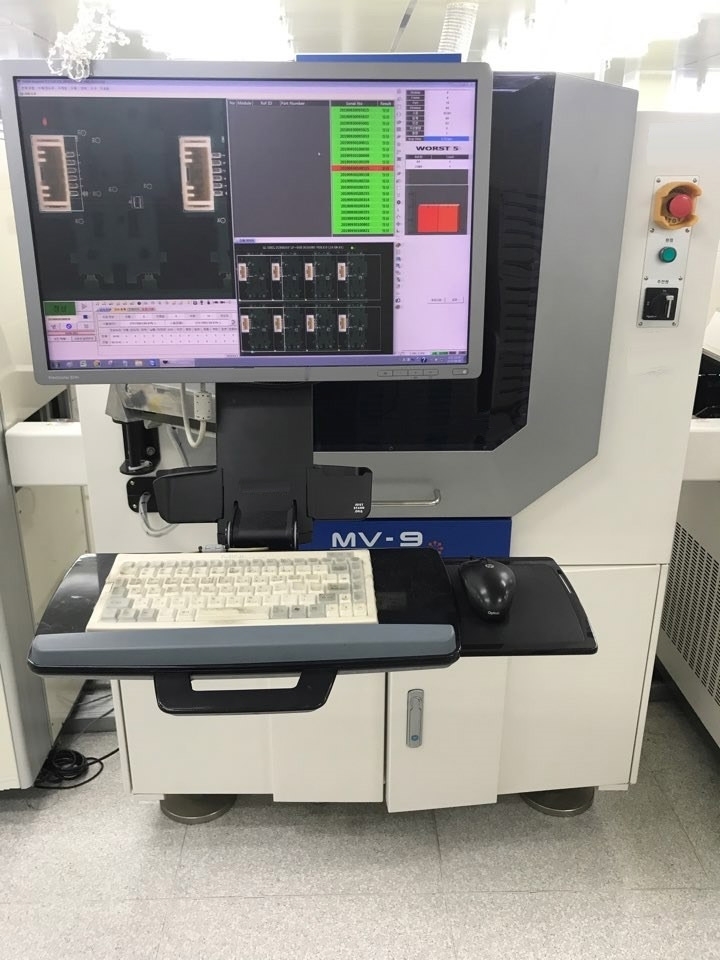

Used MIRTEC MV-9 #9228616 for sale

URL successfully copied!

Tap to zoom

ID: 9228616

Vintage: 2014

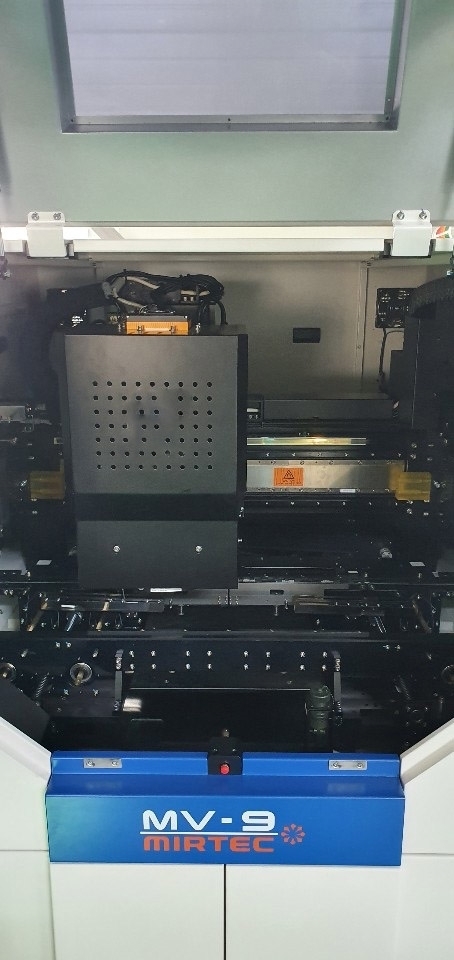

3D In-line Automatic Optical Inspection (AOI) system

Main camera

(4) Side cameras

Camera: 15M

Resolution: 15 µm

Maximum PCB Size: 510 mm x 460 mm

Left to right / Front rail fixing

2014 vintage.

MIRTEC MV-9 is a revolutionary automated PC board assembly and manufacturing equipment that provides manufacturers with a unique set of capabilities. This system includes features such as soldering, placement, and assembly capabilities. MV-9 is capable of handling ultra-fine pitch and BGA components with ease. This unit is completely open-architectured and has the ability to support multiple processes and many different models, which provides manufacturers with great flexibility. MIRTEC patented 3D SPI technology helps operators achieve the desired soldering quality and is one of the most advanced Solder Paste Inspection (SPI) systems available. The integrated vision machine provides true 3D inspection of solder paste placement accuracy, rising above the industry standard for quality inspection. This combined with the automatic fiducial and pattern recognition enhances the accuracy and repeatability of the tool. MIRTEC MV-9 has powerful motor-driven placement robot arms that provide faster cycle times and reliability. It can easily place any number of components, including (but not limited to) 0201, BGA, QFP, and PGA components, as well as all kinds of SMD devices. This asset also features Automatic Component Locating (ACL) which enables it to locate fiducial marks automatically, reducing setup time and ensuring utmost accuracy. MV-9 has a navigable 3D alignment model for quick and easy setup of varying boards and components. This feature consists of high-resolution cameras that facilitate accurate vision inspection and measurements. This ensures that components are placed accurately, saving time and eliminating the possibility of error. The inspection process on MIRTEC MV-9 is facilitated by the Advanced Tool Change (ATC) function. This provides excellent capability for inline defect inspection, allowing operators to program a variety of vision and AOI inspections. This also provides the flexibility to custom-program unique inspections for specific processes. Overall, MV-9 is an incredibly efficient equipment that provides manufacturers with powerful tools for PC board assembly and manufacturing. It features advanced features such as 3D SPI, ATC, and ACL, which make the process more reliable and accurate. This system is also open-architectured and highly flexible, allowing manufacturers to easily customize the unit to their specific needs.

There are no reviews yet