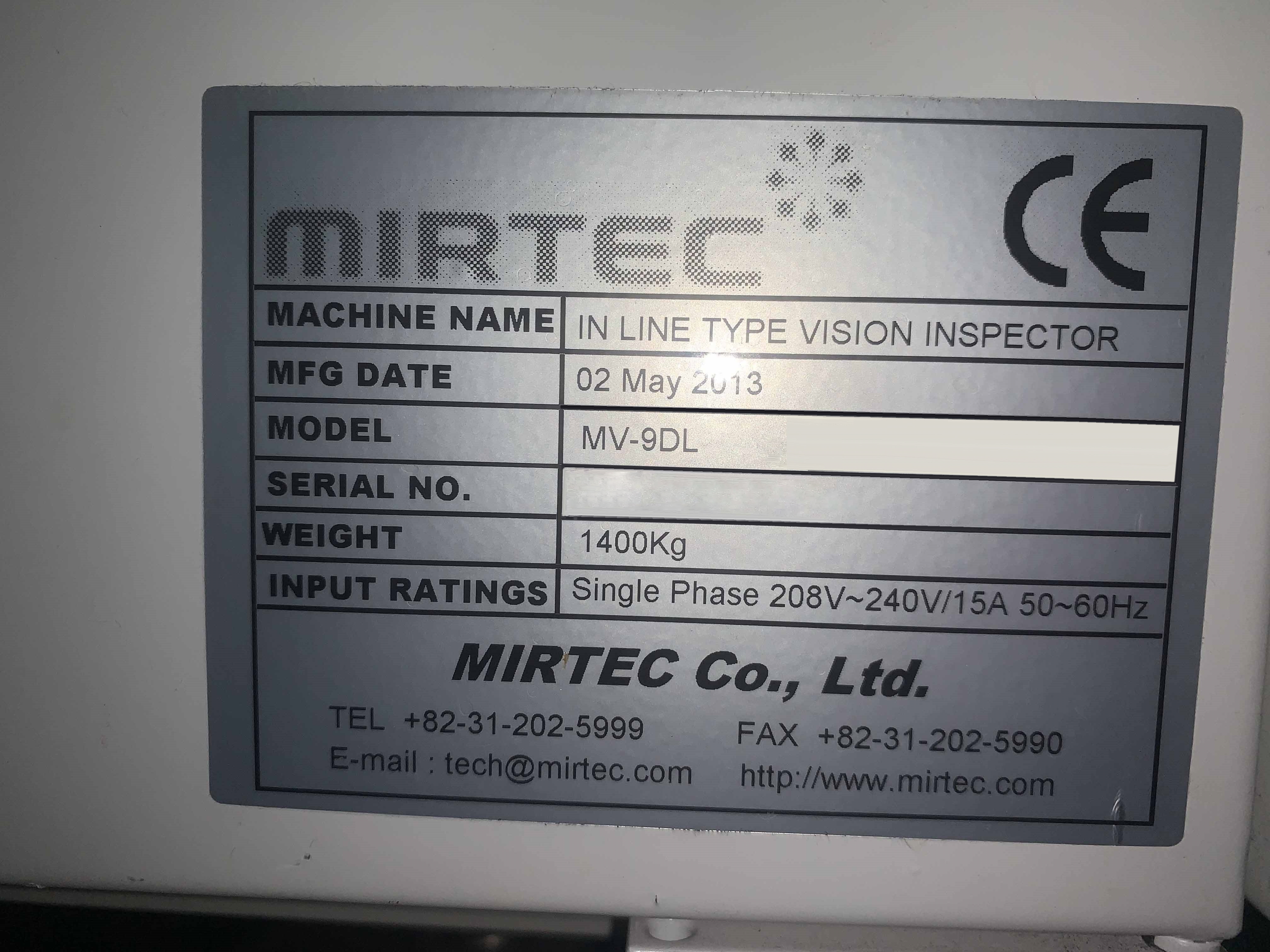

Used MIRTEC MV-9DL #9284712 for sale

URL successfully copied!

Tap to zoom

ID: 9284712

Vintage: 2013

2D In-line Automatic Optical Inspection (AOI) system

Top: 15 mega pixel camera with 10 um resolution

Side: 10 mega pixel cameras

Conveyor flow: Left to right

Conveyor type: Dual lane

Does not include 3D inspection

2013 vintage.

MIRTEC MV-9DL is a fully-automated, advanced printed circuit board (PCB) assembly and manufacturing equipment. It is designed for high-level electronic interconnection and assembly of various advanced parts. The system features built-in inspection dimensions which enhance inspection accuracy. It can inspect the accuracy of lead coplanarity, care labels, and solder joints. Additionally, it has a standard 4-motorized X/Y/Z axes and variable mounting heads that can be manipulated to adapt to various components. MV-9DL includes a sophisticated vision processing unit which uses various camera angles to measure and detect problems during production. This advanced vision machine is also able to accurately measure pad positions and dimensions. The images are then further processed in subsequent post-processing with the analysis conducted by the inspective algorithms. The tool has three different placement modules for high productivity and flexible process modules. It can also be used in either PTH (plated through-hole) or SMD (surface-mount device) mode. In PTH mode, components can be claimed from reels with up to 24mm widths and up to 8mm thicknesses. In SMD mode, it can take components up to 20x20mm in size. The mounting speed of MIRTEC MV-9DL reaches its peak when 3,500 parts can be placed in an hour while 6,400 parts per hour can be placed in SMD mode. Its wave soldering capability is suitable for lead-free soldering and can be used in both PTH and SMD modes. Moreover, the MX-9DL also provides Smart Assessment capabilities which enable on-line X-Ray inspection for micro-BGA and other critical components. This capacity reduces extra inspection time and resource costs by providing a real-time solution and feedbacks to the operators. With improved accuracy, speed, and inspection capacity, MV-9DL is a reliable asset for the assembly and manufacturing of PC boards. It provide users with an advanced, integrated approach to high-precision PC board production.

There are no reviews yet