Used MRSI 170 #9096294 for sale

URL successfully copied!

Tap to zoom

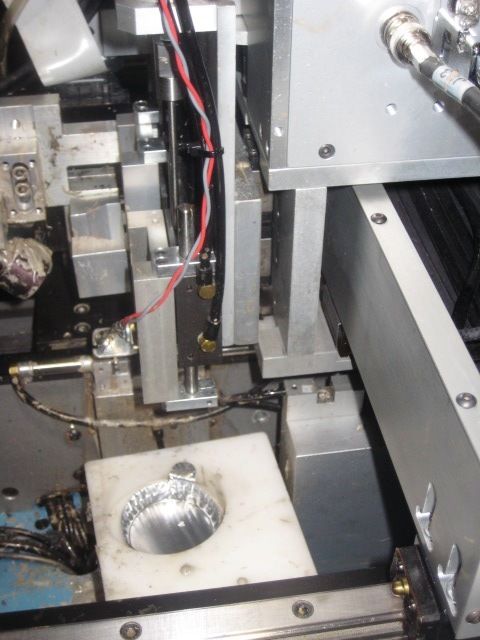

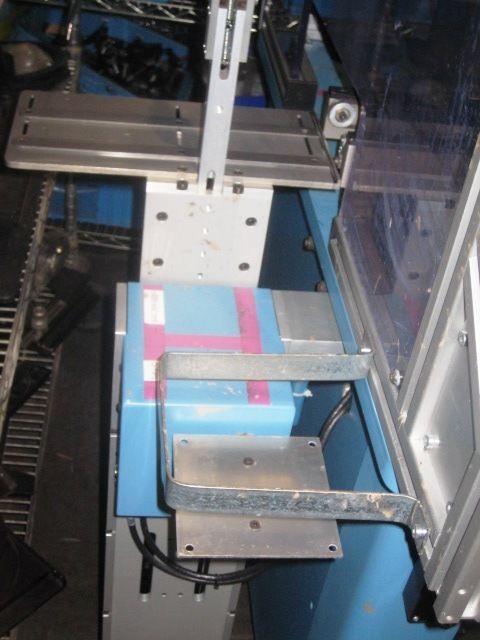

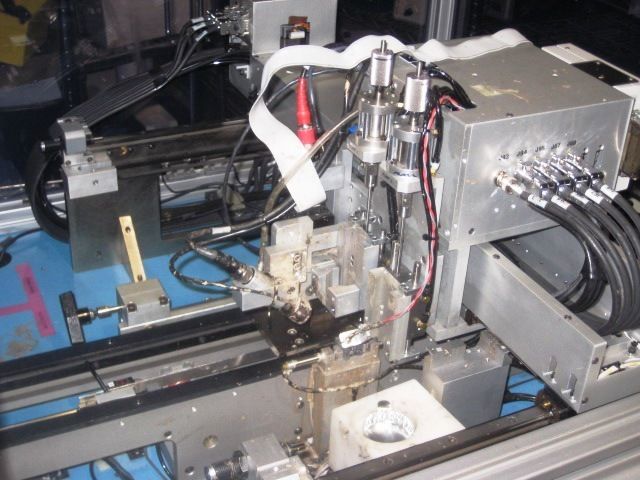

MRSI 170 is a state-of-the-art PC Board Assembly and Manufacturing Equipment designed to provide high-quality automation with superior throughput and flexibility, allowing for the efficient production of both small volume and high-volume boards. The system features a dual-head screwdriver for fast and accurate insertion of components, as well as high-speed placement of odd-form components. An integrated vision unit and fiducial tracking enable precise location and placement of components on the board. Specialty nozzle design and placement tooling ensure reliable and repeatable placement of components, while a range of I/O interfaces and software applications offer compatibility with most production control systems. 170 also offers integrated feeder and tool support, allowing for quick installation and retrieval of feeders and tools, as well as a scaleable machine from four to sixteen heads. MRSI 170 is equipped with an advanced vision tool, which can detect component orientation and orientation verification of low-cost, high-volume components. A proprietary feeder concept is used for accurate placement and automatic insertion of many component types. The asset also features an innovative printing model, which uses touch sensors to verify the printing of solder paste on all pads. 170 PC Board Assembly and Manufacturing Equipment is designed with high-efficiency and flexibility to ensure that production is accurate and yields are maximized. MRSI 170 is designed with a wide range of diagnostics and monitoring features such as a calibration and diagnostic station, which can monitor the accuracy of each nozzle and diagnose issues with nozzles or feeders. The system also offers comprehensive logging and statistical process control to allow analysis of production data and to enable operators to ensure the highest quality. The integrated vision unit also provides defect inspection capabilities, ensuring that boards are free from defects and have perfect registration. In addition, 170 offers a range of communications and interface options to integrate into existing and new production control systems. External monitoring and programming can be done through USB, Ethernet, GP-IB and other standard interfaces. The machine is also compatible with a number of industrial-grade PLC systems, which provide the flexibility to accommodate future production requirements. MRSI 170 also features a range of additional integrated features including moisture-resistant construction for reliable operation that meets industry standards for durability and performance; RoHS & REACH compliance; CE & UL compliant electronics; energy-efficient motors; and 3-year warranty. With a robust and reliable platform, 170 is a complete solution for PC Board Assembly and Manufacturing.

There are no reviews yet