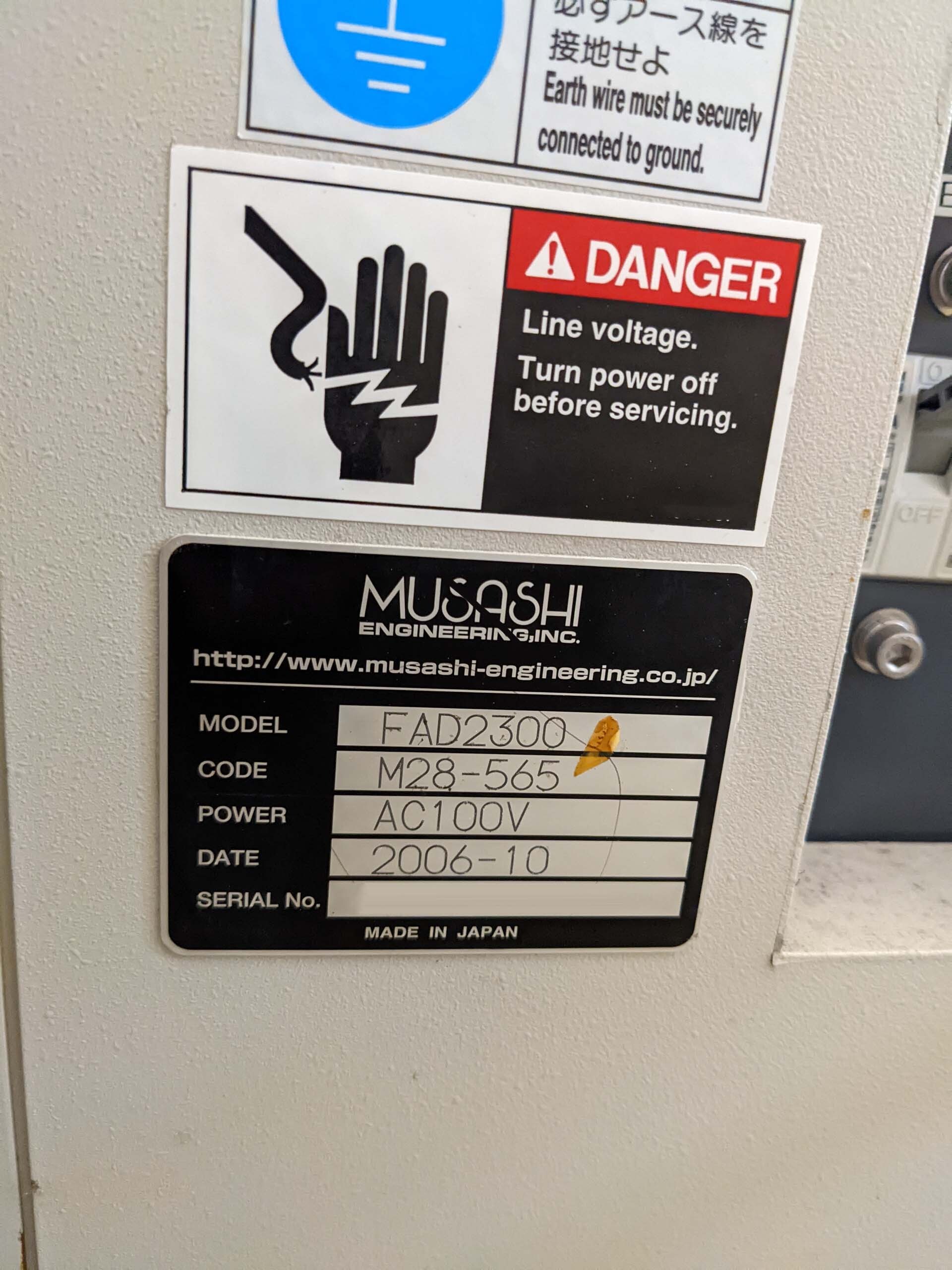

Used MUSASHI ENGINEERING FAD 2300 #293634931 for sale

URL successfully copied!

Tap to zoom

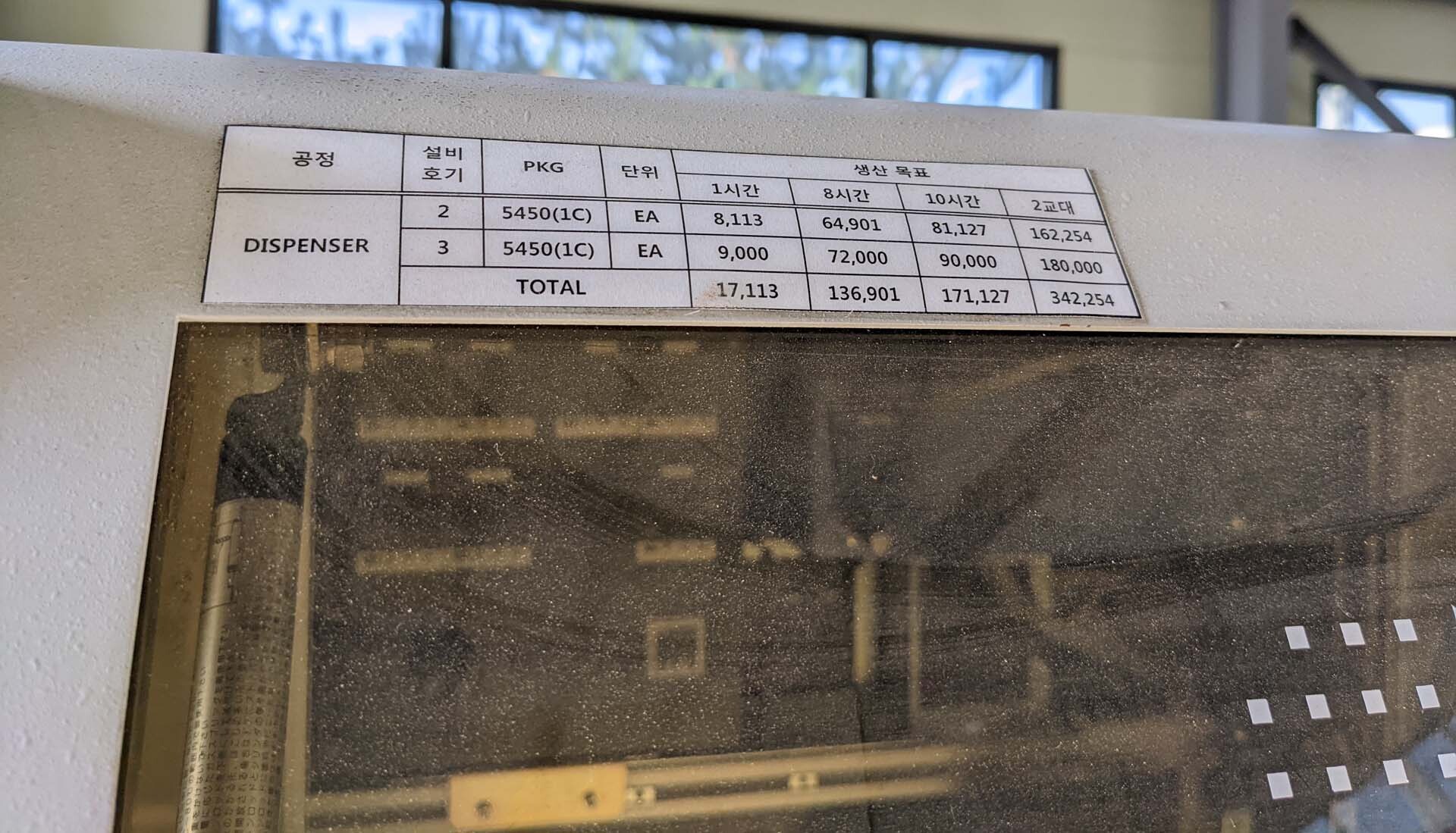

MUSASHI ENGINEERING FAD 2300 is a state of the art pc board assembly and manufacturing equipment specifically designed to improve the fabrication of printed circuit boards. It is a machine-mount chart processor system, which uses a high-speed, interchangeable chart processor that can be integrated into other industrial systems. FAD 2300 was designed to be a complete engineering package with full hardware automation and process controls. The machine is composed of two main components: the I/O Control Unit (ICU) and the Controlled Environment (CE). The ICU is a power supply, data acquisition, monitoring, and controller board designed to support the operation of all components of MUSASHI ENGINEERING FAD 2300 unit. The ICU features a solder pot control machine, a built-in soldering tip cleaner, solder paste control, and clean solder optimization. The CE is a closed loop, in-process gas supply tool. It is a vacuum-controlled flow, heated oven, and process gases monitoring asset. FAD 2300 includes a dual-channel PC board manufacturing model. It can process multiple layers of various materials within a single step. Its patent-pending board transport equipment ensures smooth loading and unloading of panels, and a vision system facilitates real-time inspection and quality management. The unit also has an R2R (roller-to-roller) automated placement machine that applies solder paste, orients and places components, and reflows them accurately with minimal setup time. Additionally, it has a vision inspection tool that automatically inspects components placement, solder paste quality and surface mount assemblies before and after reflow. MUSASHI ENGINEERING FAD 2300 also includes a flexible software suite with a modern user interface, allowing users to configure, operate, and monitor the asset quickly and easily. It operates with both real-time and stored data, providing greater analysis, storage, and reporting capabilities. FAD 2300 is a highly automated pc board assembly and manufacturing model that can increase efficiency, reduce costs, and ensure quality manufacturing. The combination of PC board manufacturing, process controls, and software makes it a powerful and reliable tool for any manufacturing or engineering needs.

There are no reviews yet