Used MUSASHI ENGINEERING FAD 2500 #293654218 for sale

URL successfully copied!

Tap to zoom

ID: 293654218

Dispenser

Non-contact laser height measurement

Automatic correction function of dispensing amount

Tip temperature adjustment

Loading and unloading: (3) Boxes

Piezoelectric valve

Repeatability: ± 4 um Location repeatability

Maximum substrate: W330 mm x D250 mm

Super Jet-F:

Jet for UF fine dispensing: 500shot/sec

Compatible material viscosity: 0.05 - 300Pa

Nozzle heating: Max 60°C (Heat / Cooling)

Material supply: All syringes, tank

Die size: 1.5 mm x 1.3 mm

Min RBI (On glass): φ 0.2 mm

UF Material: 2~40 μg / shot

Frequency: 500 Hz.

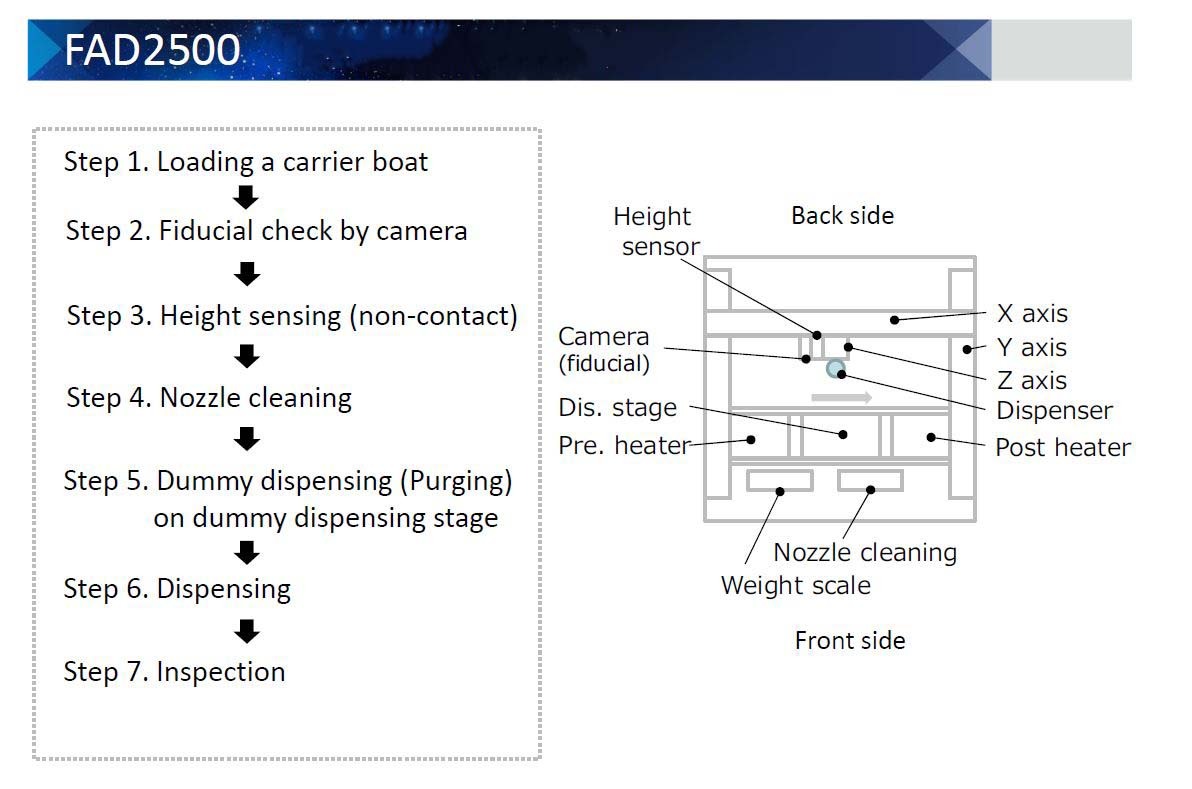

MUSASHI ENGINEERING FAD 2500 is a PC board assembly and manufacturing equipment designed for accuracy and speed. FAD 2500 is capable of handling single parts as small as 0201 and up to boards of 470mm x 470mm sizes. MUSASHI ENGINEERING FAD 2500 is a fully automated system able to form, place, and secure many types of components; chips, QFPs, BGAs, resistors, capacitors, connectors, relays, and fuses. FAD 2500 is equipped with two nozzles and two suction cup heads ensuring a secure placement of components. It is precisely guided by an X-Y-Z positioning stage along with a high precision servo driven ACMT head. MUSASHI ENGINEERING FAD 2500 is designed with an intelligent Line Trace Recognition (LTR) unit to pick the parts correctly without missing, and the built-in Auto Calibration tool ensures accurate placement of parts. FAD 2500 also has the ability to accurately cut and mark the artwork in trace patterns and other shapes with high accuracy. MUSASHI ENGINEERING FAD 2500 uses a fully loaded FAD-Engineer software to program the machine for automatic execution. The FAD-Engineer software permits a wide range of settings for PCB design, component placement, lead/surface mount settings, panelization and inspection settings. FAD 2500 includes an Advance Network Connectivity (ANC) feature that enables the tool to be connected to a network asset and provides the ability to access data from multiple machines at the same time. Safety features have been built in to protect personnel from accidents and the model from damage. Dual laser sensors are incorporated to detect intrusions and the presence of personnel in the working area. MUSASHI ENGINEERING FAD 2500 is an ideal equipment for high accuracy and speed assembly and manufacturing of PC boards. Its intelligent Line Trace Recognition system ensures accurate placement of parts, and its Network Connectivity feature allows efficient performance with multiple machines. FAD 2500 is a great addition to any facility looking to increase efficiency and accuracy in assembly and manufacturing.

There are no reviews yet