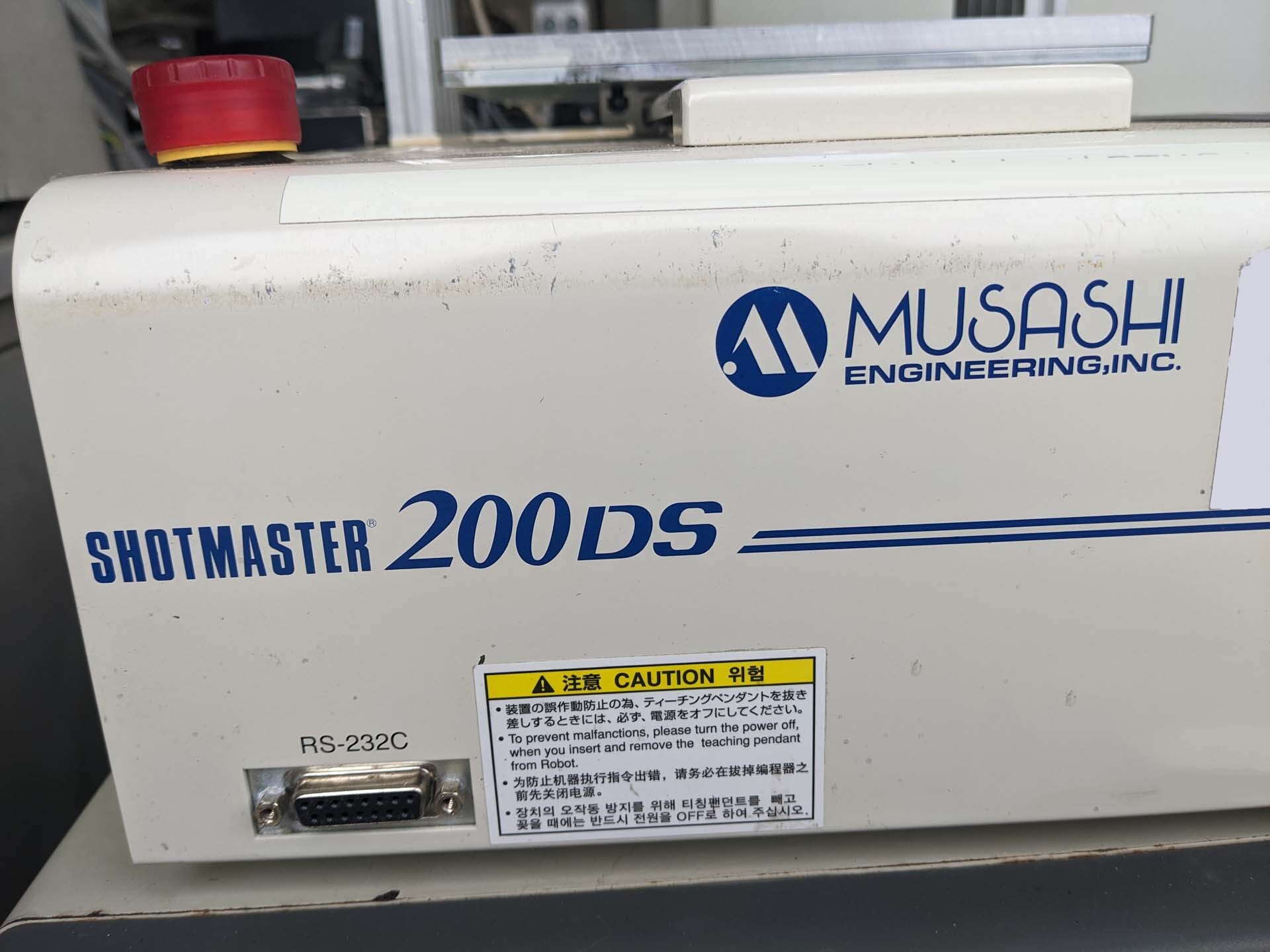

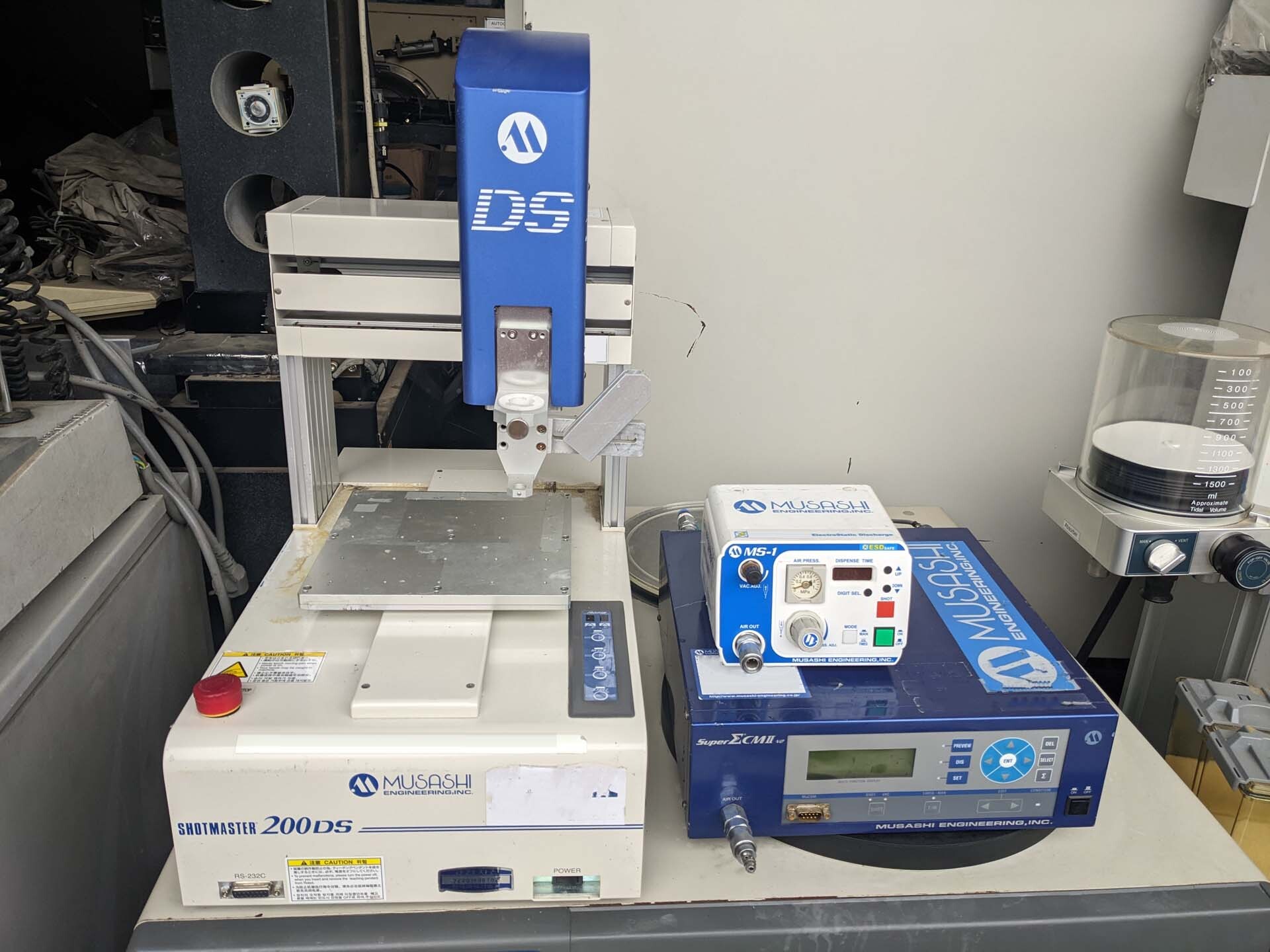

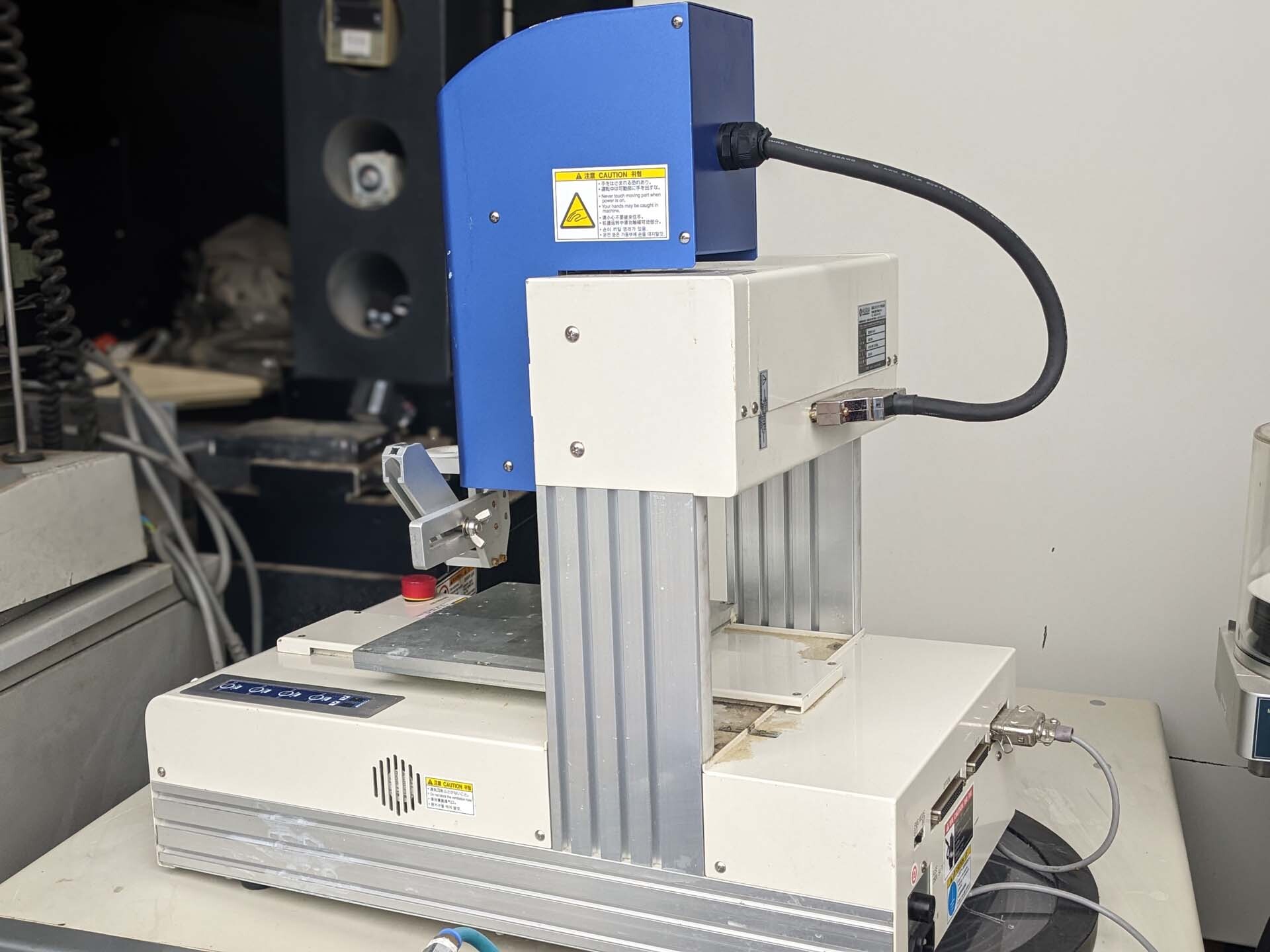

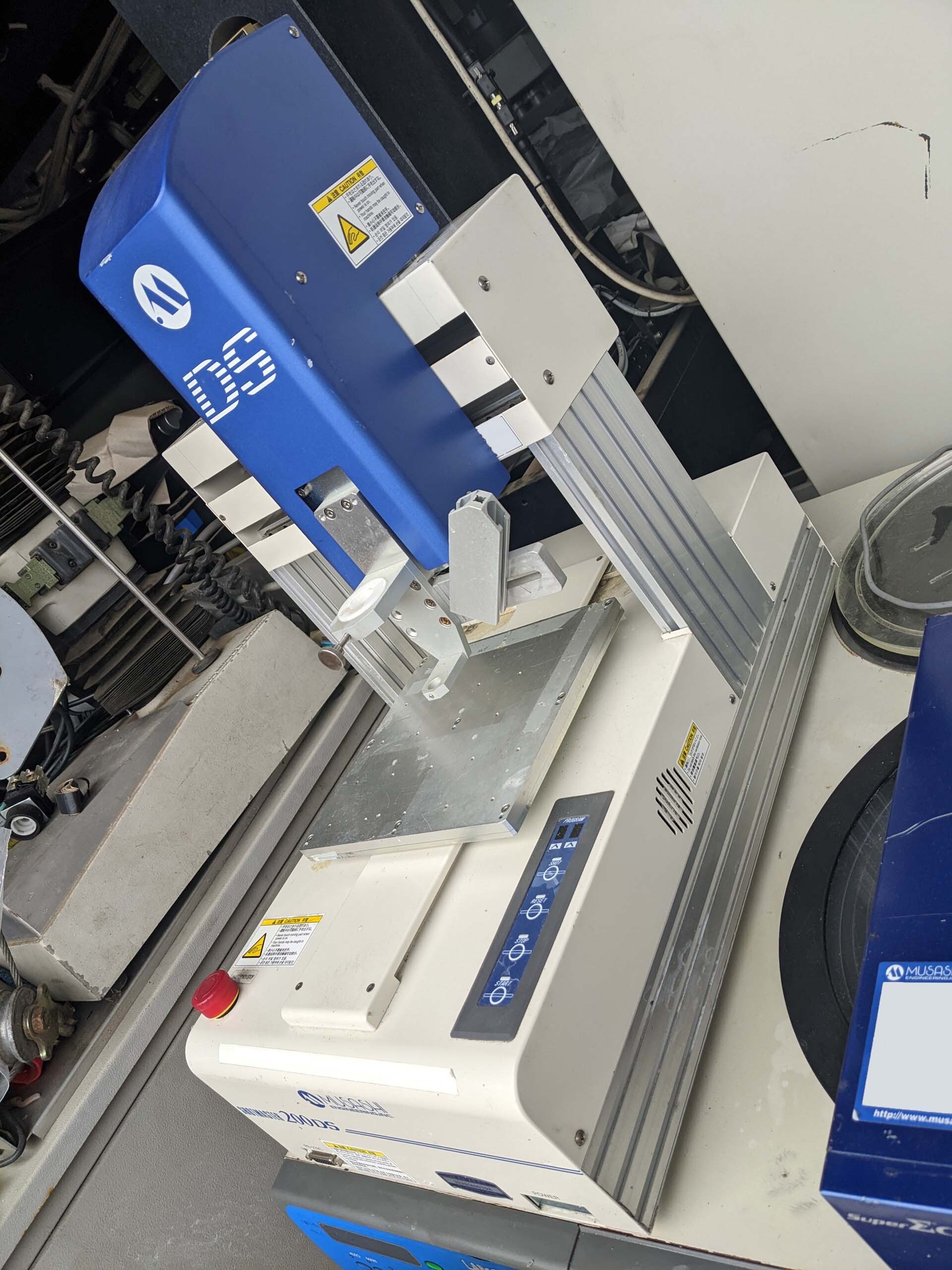

Used MUSASHI ENGINEERING SHOTMASTER 200DS #293635213 for sale

URL successfully copied!

Tap to zoom

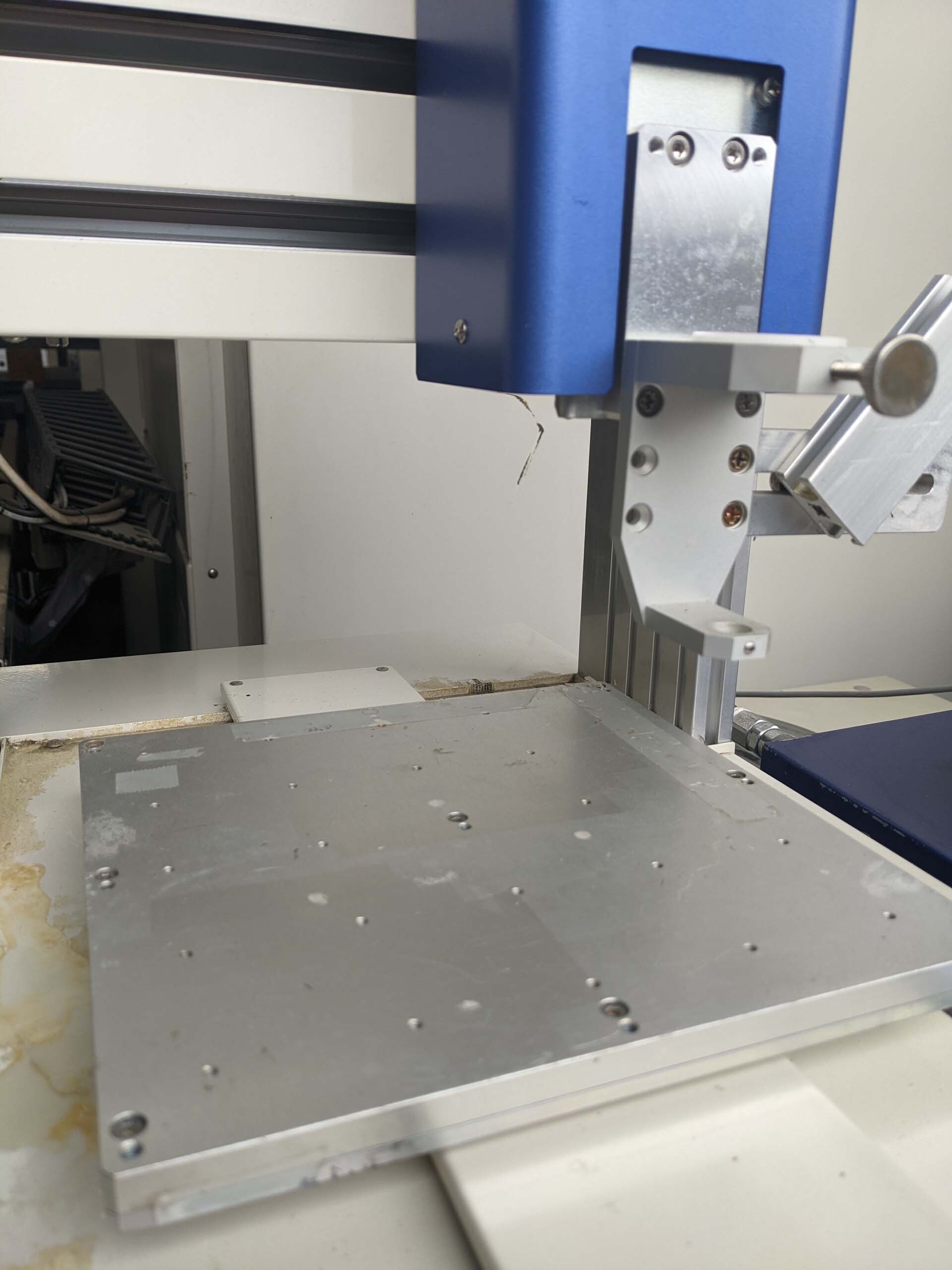

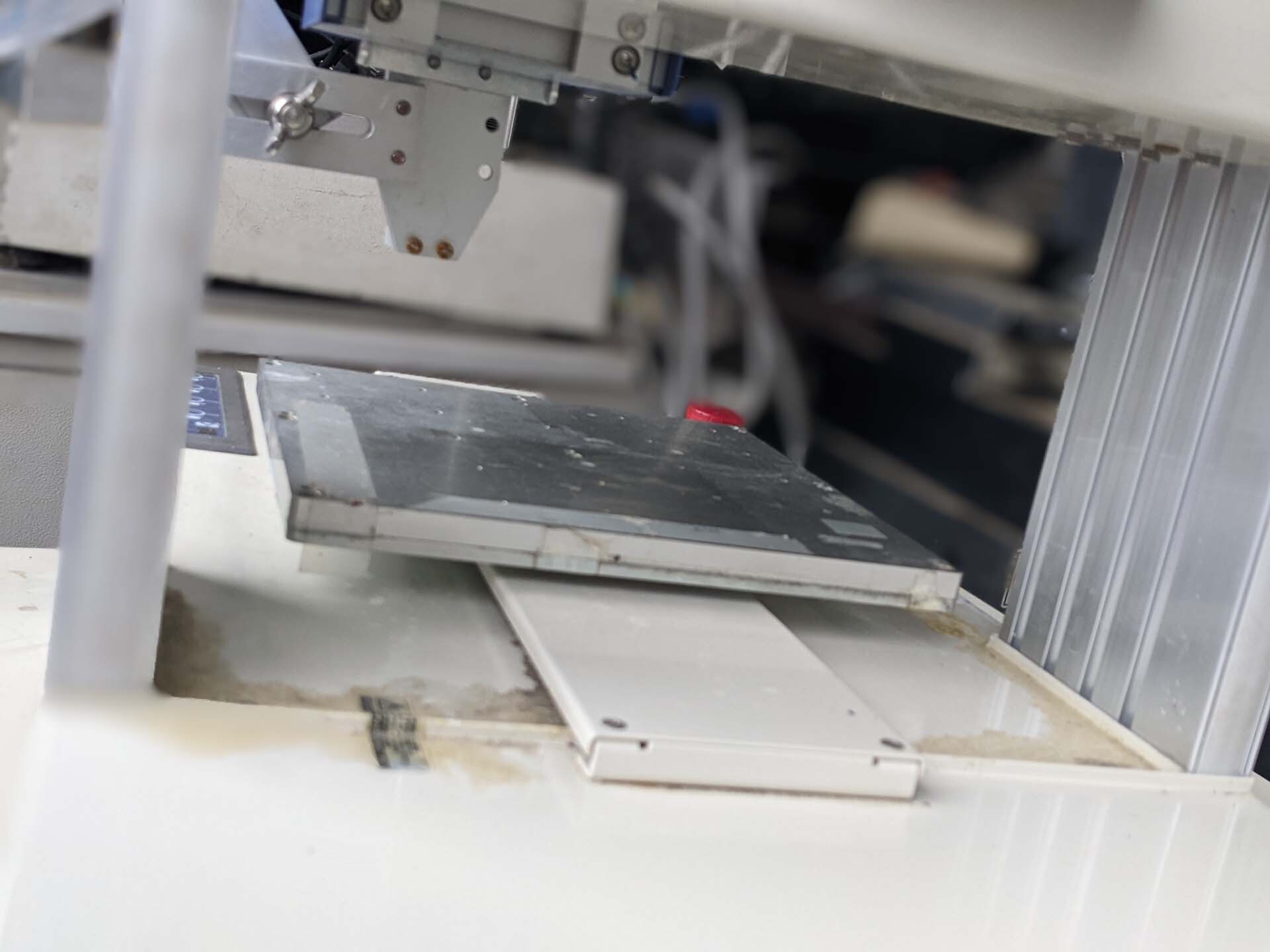

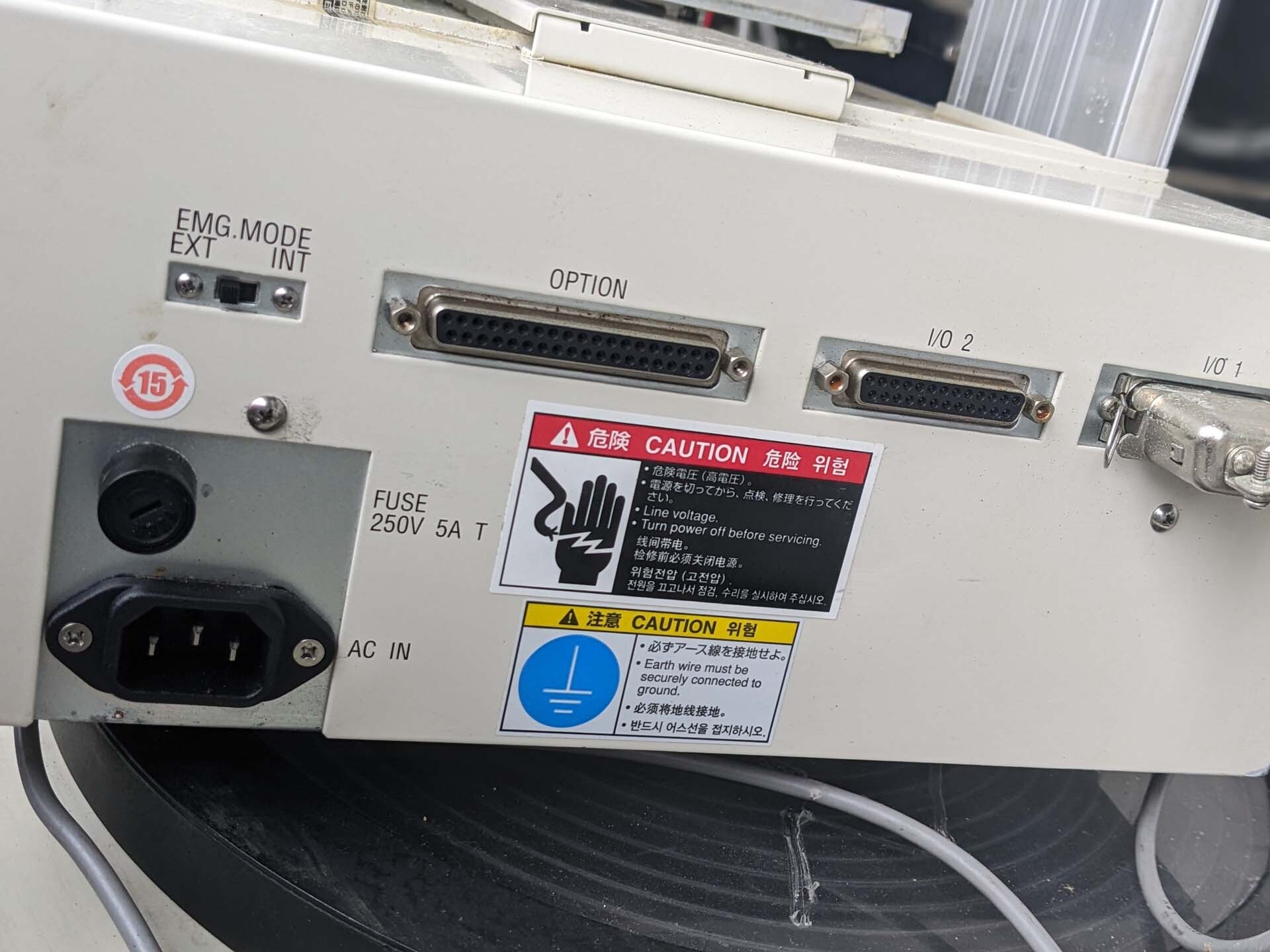

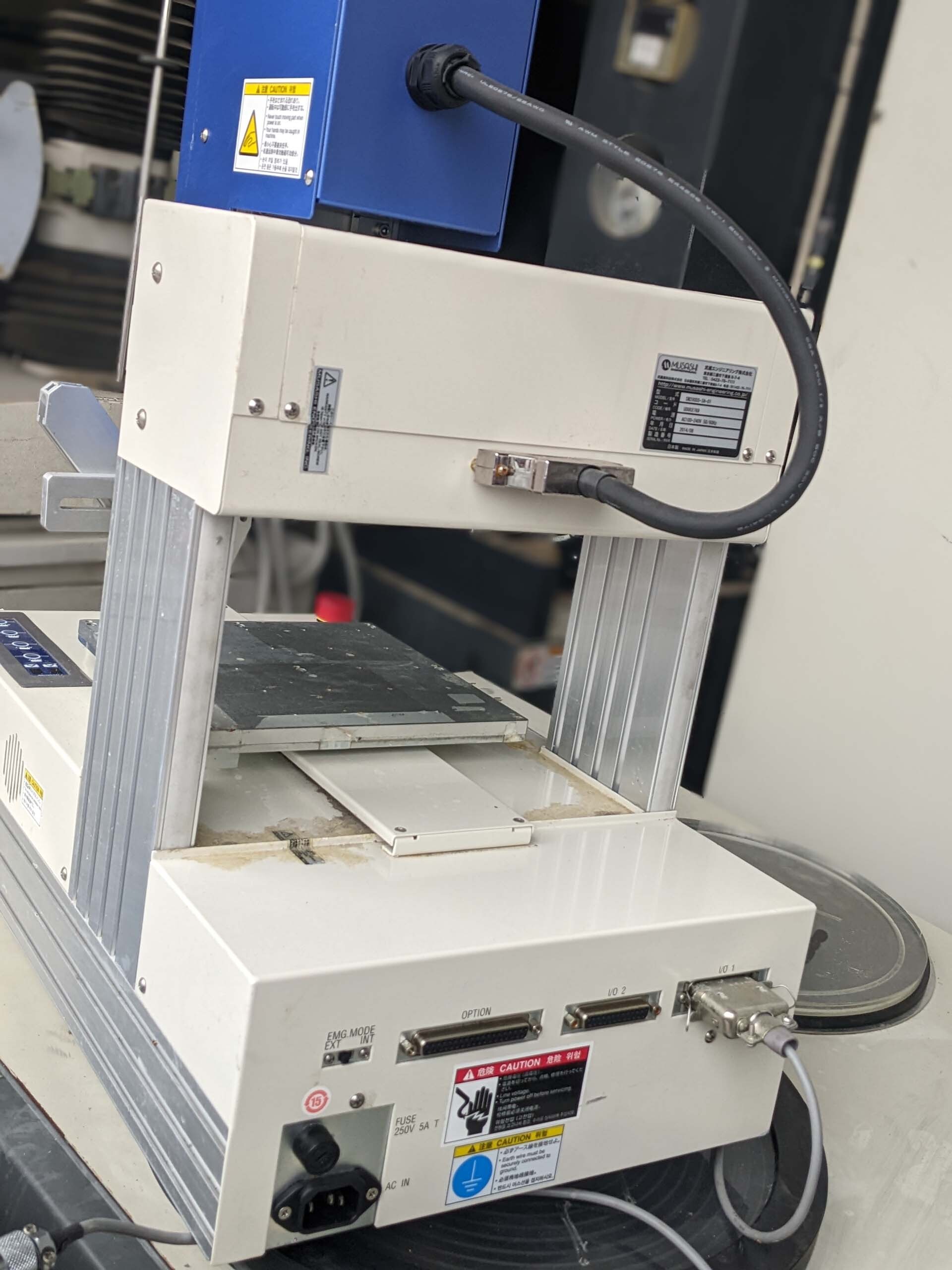

MUSASHI ENGINEERING SHOTMASTER 200DS is a leading edge PC board assembly and manufacturing equipment. It is a high precision, automated system ideal for high volume production. The unit recognizes and inspects various components, applies bonding materials, connects components, and tests for defects. SHOTMASTER 200DS incorporates an industrial-grade CNC machine that automatically moves components around the board before and during assembly. Its advanced CNC machine utilizes express-flex technology so that circuit paths and connection points can be easily customized. It features a high-resolution imaging machine that performs intricate, high-speed optical inspections to ensure quality and accuracy. Its soldering tool uses a wide range of hot air, laser, and soldering techniques that allow for the most precise connections possible. MUSASHI ENGINEERING SHOTMASTER 200DS supports a variety of components, including BGA, QFP, LGA, PLCC, and WLCSP packages. Its advanced placement head allows access to components in cramped spaces, making it perfect for applications with low package clearance. It also has a thermal setup that allows users to laser-weld complex and multi-level designs. SHOTMASTER 200DS is designed to enable easy and efficient operation. Its intuitive user interface and comprehensive data management allow users to focus on production rather than complicated setup and programming. Its diagnostic and testing features help detect errors quickly and help improve process quality. This full automation asset is designed to increase production and reduce costs. MUSASHI ENGINEERING SHOTMASTER 200DS provides high-speed and high-accuracy processing that makes batch production fast and cost-efficient. It also increases consistency and reliability. With its express-flex technology and its advanced testing functions, users can achieve results with little or no human intervention. SHOTMASTER 200DS is a great choice for any manufacturing application that requires high-volume production. This highly reliable, automated model is ideal for any production line. It allows for detailed and intricate inspections for increased accuracy and product quality. It also has many user-friendly features so that users can quickly and easily set up and program the equipment.

There are no reviews yet