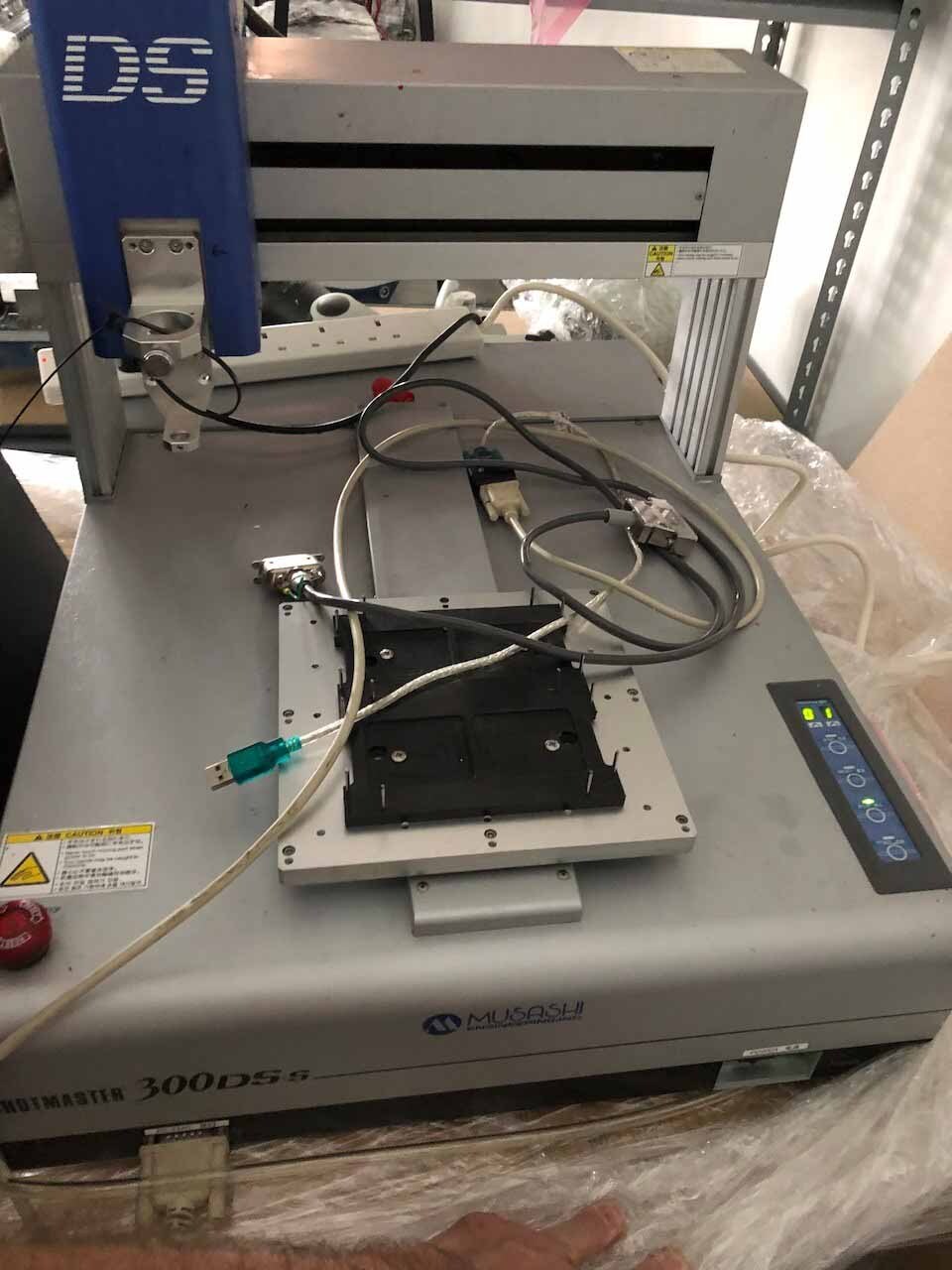

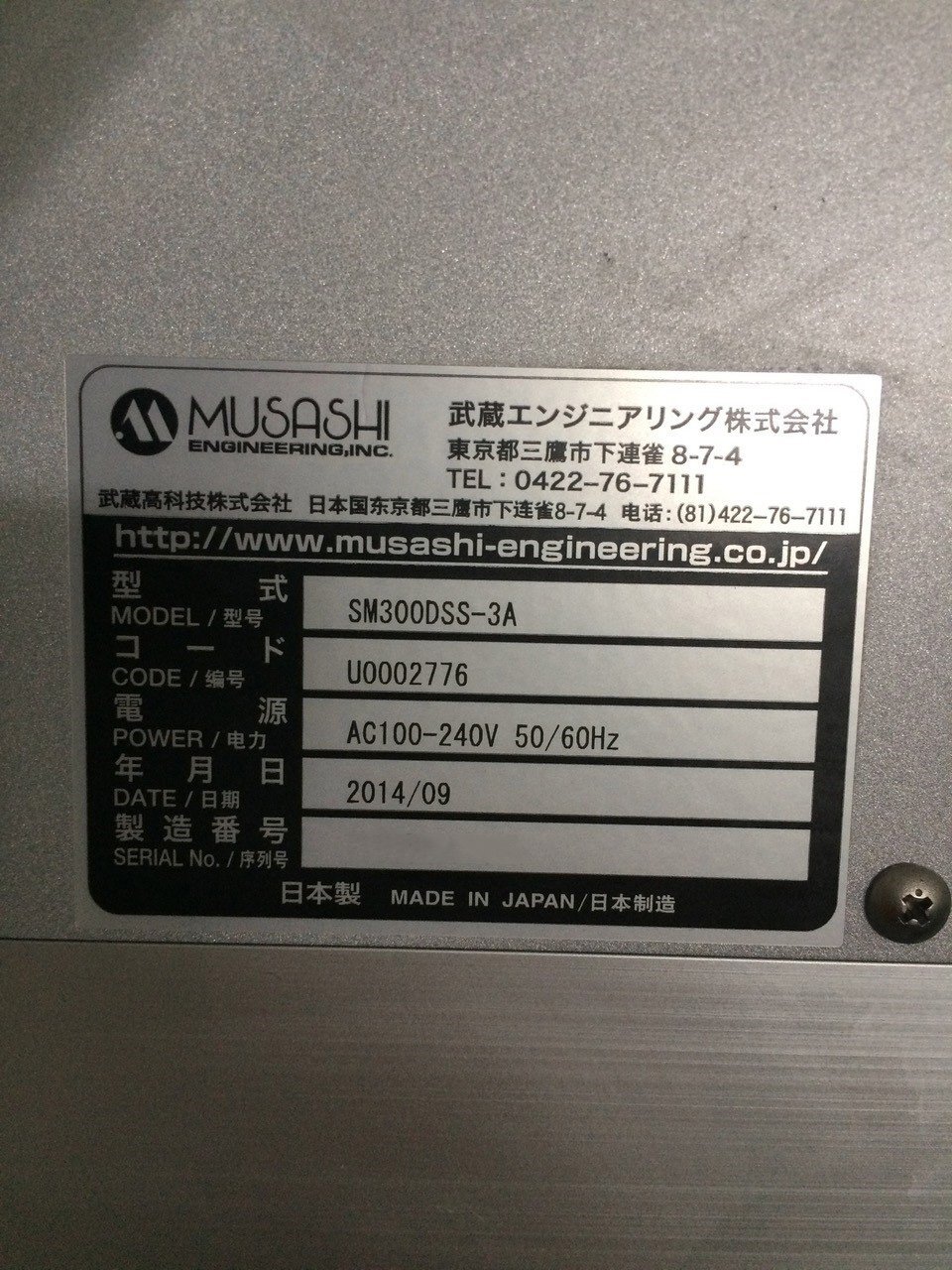

Used MUSASHI ENGINEERING SM300DSS-3A #9356082 for sale

URL successfully copied!

Tap to zoom

MUSASHI ENGINEERING SM300DSS-3A is a fully automated PC board assembly and manufacturing equipment. It features a host of functions designed for maximum efficiency and cost savings, including an intelligent component placement system, a soldering unit that utilizes a recently developed screen printing paste process, and a high-performance inspection machine. The intelligent component placement tool combines advanced servo motors, vision systems, and a highly accurate flight path control asset to accurately place each component in an extremely short period of time. This model also allows for component detection, double checking, and real-time monitoring, to ensure each piece of the board is correctly placed and soldered. The newly developed screen printing paste process uses a durable mesh for the transfer of solder to create a seamless transition with minimum residue, maximizing the stability of electronic-board structures. Inspection is also an important part of SM300DSS-3A equipment. It includes an online full-board comparison system and a high-accuracy measurement and inspection unit to check whether all components have correctly formed solders. This ensures that any defects can be detected before the board is tested or released. Additionally, this machine includes traceability for fully automated abnormality reporting and follow-up, and has been certified for long-term stability. To protect products and equipment, MUSASHI ENGINEERING SM300DSS-3A features a fully sealed design to prevent dust and dirt from entering the tool. Additionally, the asset has a closed air circulation feature to create a pollution-proof environment for the production process. This feature ensures a consistent and clean work environment, while reducing the potential for workplace fatigue due to inhaling harmful particles. SM300DSS-3A also offers multiple safety features for both its users and the components it processes. This includes 3-stage safety checks, an emergency stop button, overload sensors, and a vibration model to indicate any malfunction. With these features in place, the equipment ensures that safety is maximized, while further minimizing potential damage to components. In conclusion, MUSASHI ENGINEERING SM300DSS-3A is an all-in-one system for PC board assembly and manufacturing. Its combination of advanced servo motors, vision systems, and screen printing paste transfer technology, ensures rapid and accurate component placement with minimal risk of errors. Its high-performance inspection unit also ensures that any defects can be quickly detected before the board is released. Additionally, the machine boasts multiple features that help ensure the safety of both its users and the components it produces.

There are no reviews yet