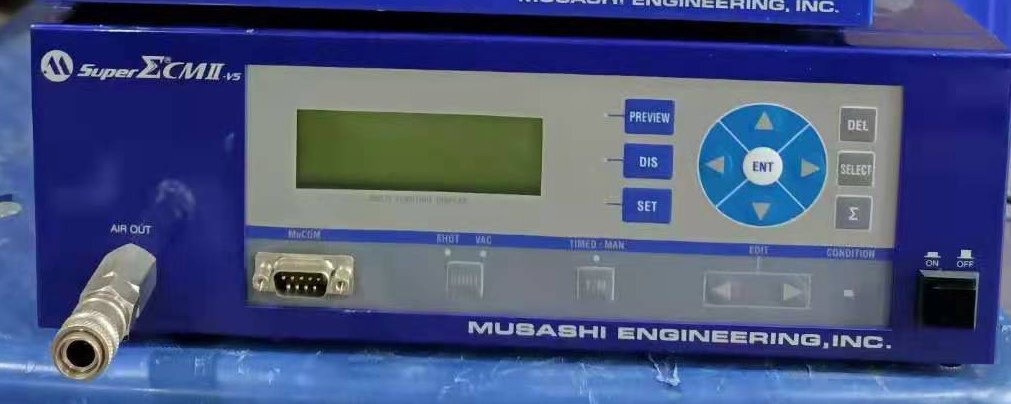

Used MUSASHI ENGINEERING SuperΣCMII-V5 #9389580 for sale

URL successfully copied!

Tap to zoom

MUSASHI ENGINEERING SuperΣCMII-V5 is a comprehensive PC board assembly and manufacturing equipment that covers all major production processes. It consists of a highly flexible, semi-automatic integrated pick and place system, an oven reflow unit, an advanced inspection machine and a hilighting tool. The pick and place asset offers precision placement capabilities for PC boards and components up to 120mm wide, and is capable of handling a wide range of components including: small ICs, larger mechanical parts, through hole components, and odd shaped parts. The model also includes a 5-axis manipulator for optimal placement accuracy on uneven boards. It is equipped with placement speed settings and error compensation functions to achieve efficient and accurate placements. The oven reflow equipment utilizes high temperature infrared heating to complete the soldering process. The temperature is carefully monitored to ensure that all components are soldered correctly and securely. The system allows for precise temperature profile control based on the component materials, the types of solder paste used, and the desired results. The advanced inspection unit is capable of checking the structural integrity of the board after assembly. It is equipped with an accurate optical vision machine and image processing software to detect visible defects, such as open/ missing connections, bridges, or misplaced components. The tool also inspects the board electrically to make sure that all connections are properly soldered and that the desired signal values are achieved. The highlighting asset helps to increase production efficiency by automating the labeling process for finished boards. The model is capable of accurately placing one or multiple labels on the board using an efficient printing equipment. It is also capable of printing multiple labels with different characteristics on different surfaces. SuperΣCMII-V5's comprehensive PC board assembly and manufacturing system attempts to provide the highest level of quality and accuracy for all production processes. Its highly flexible and semi-automatic unit helps to ensure that each board is produced efficiently and accurately. Its advanced inspection machine and highlighting tool further increase production efficiency while still conforming to the highest quality control standards.

There are no reviews yet