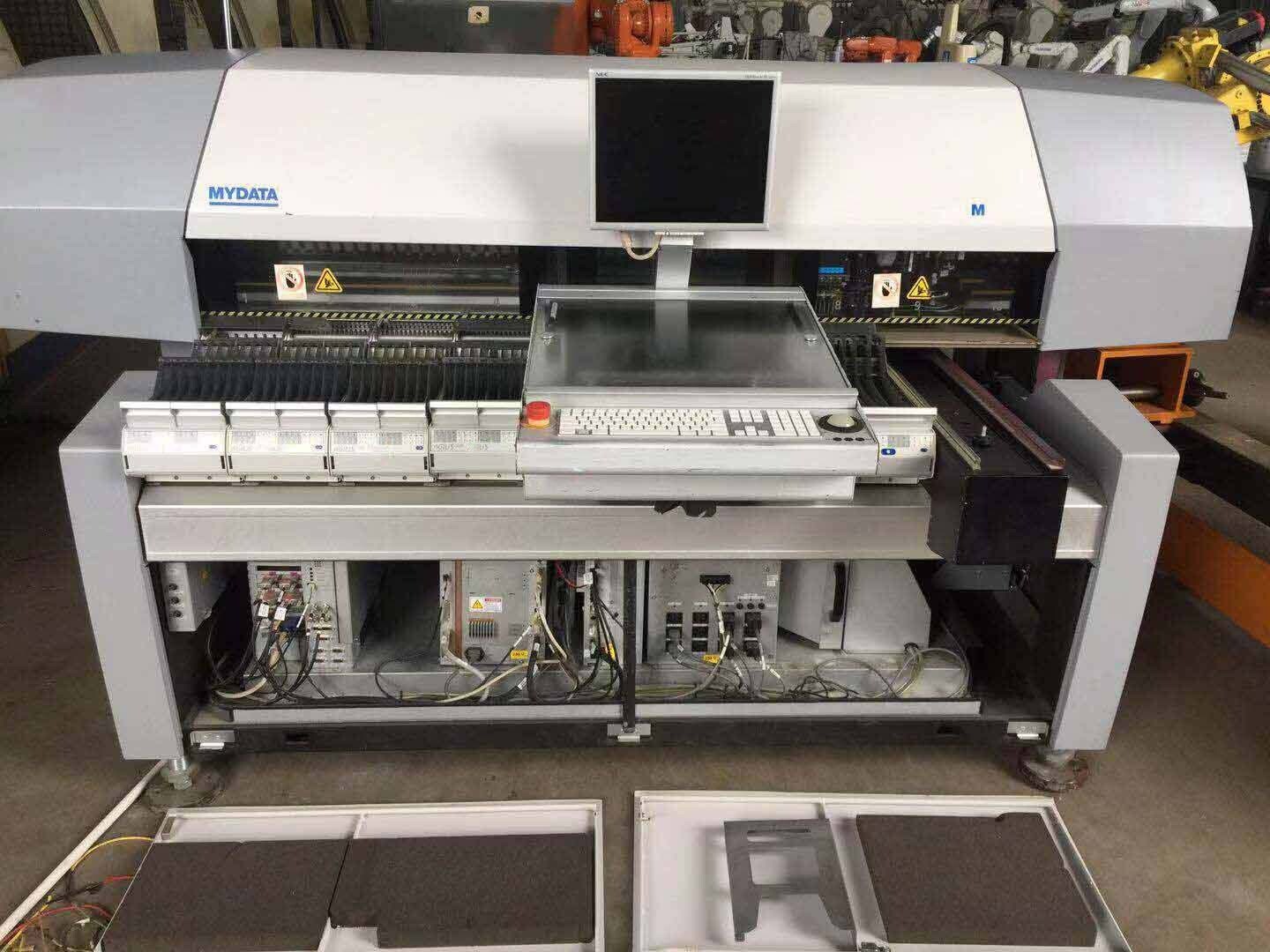

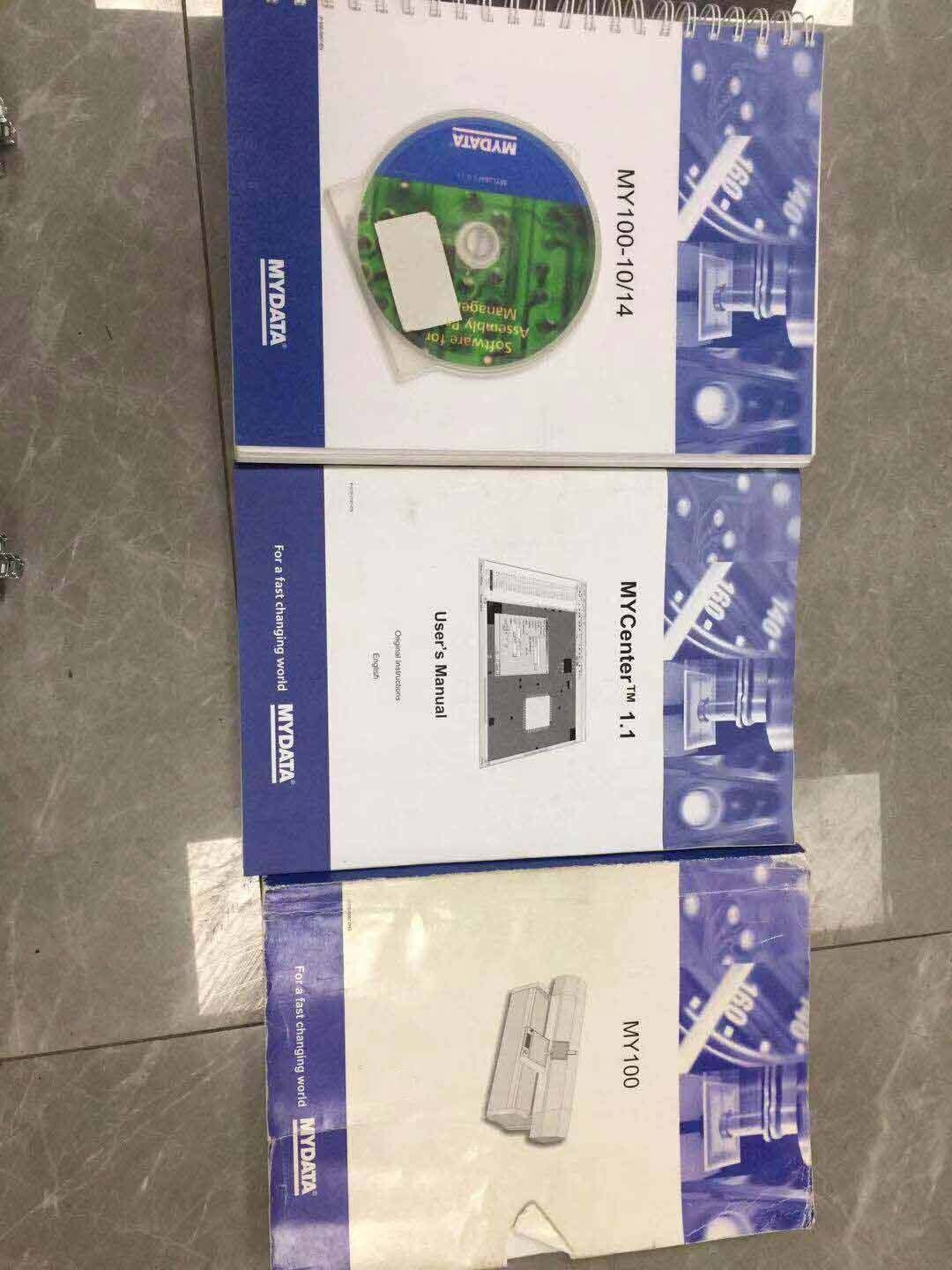

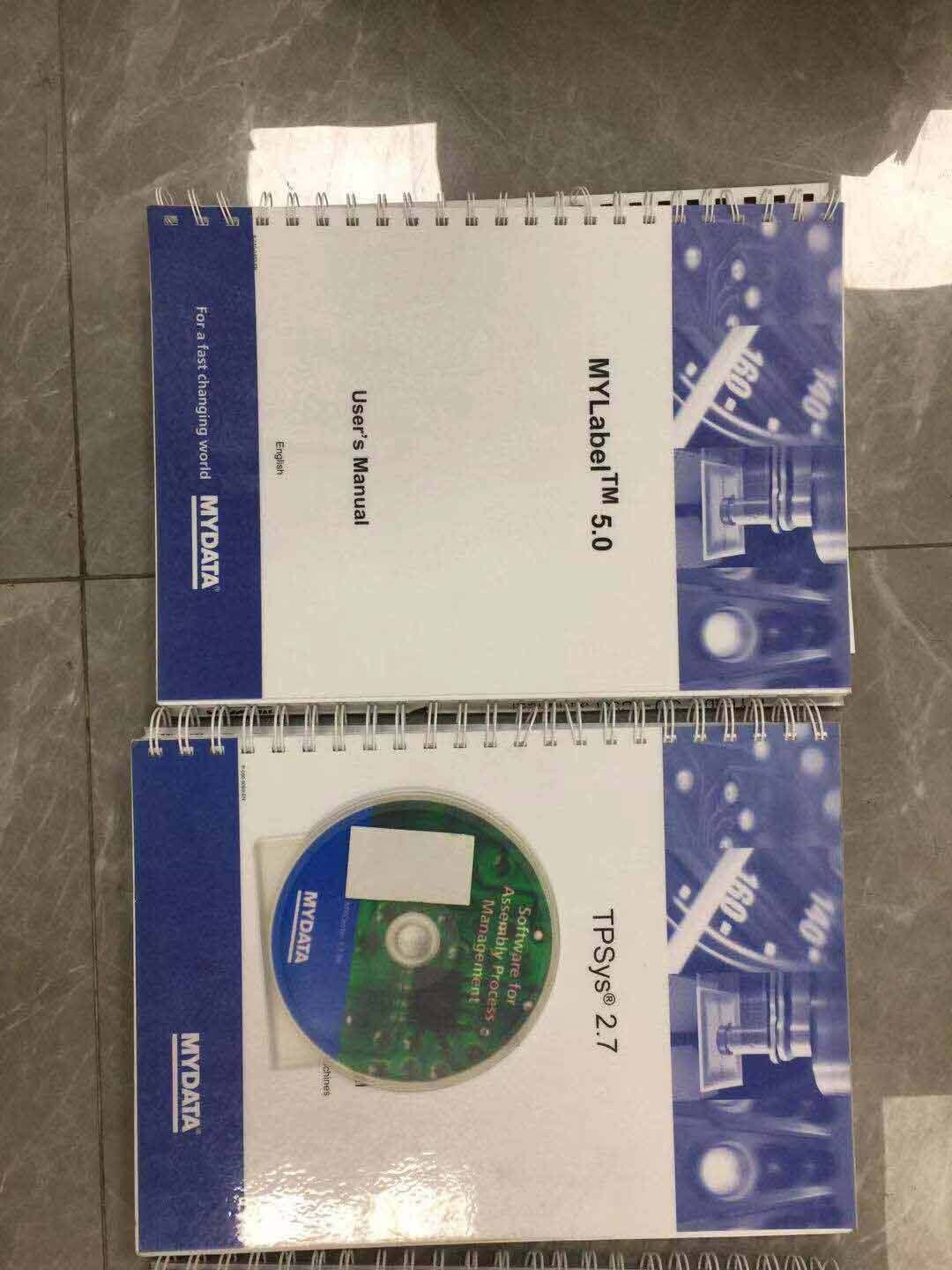

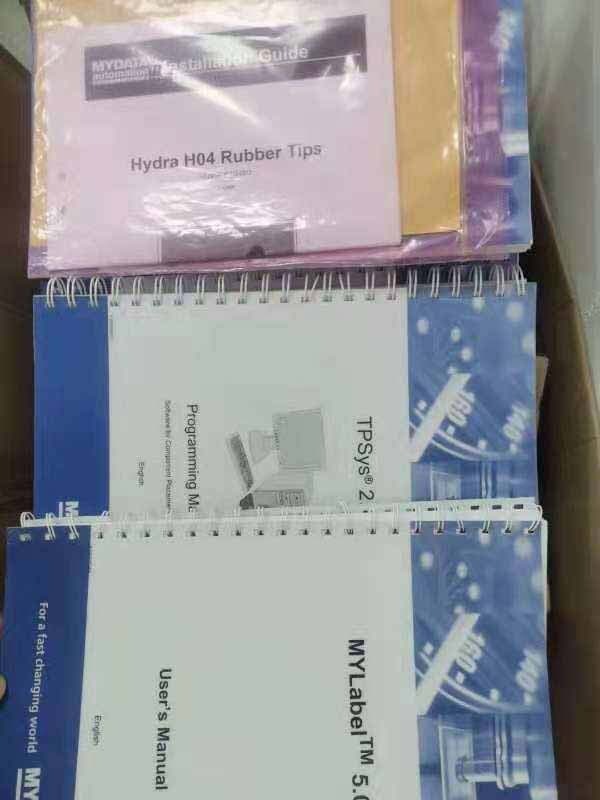

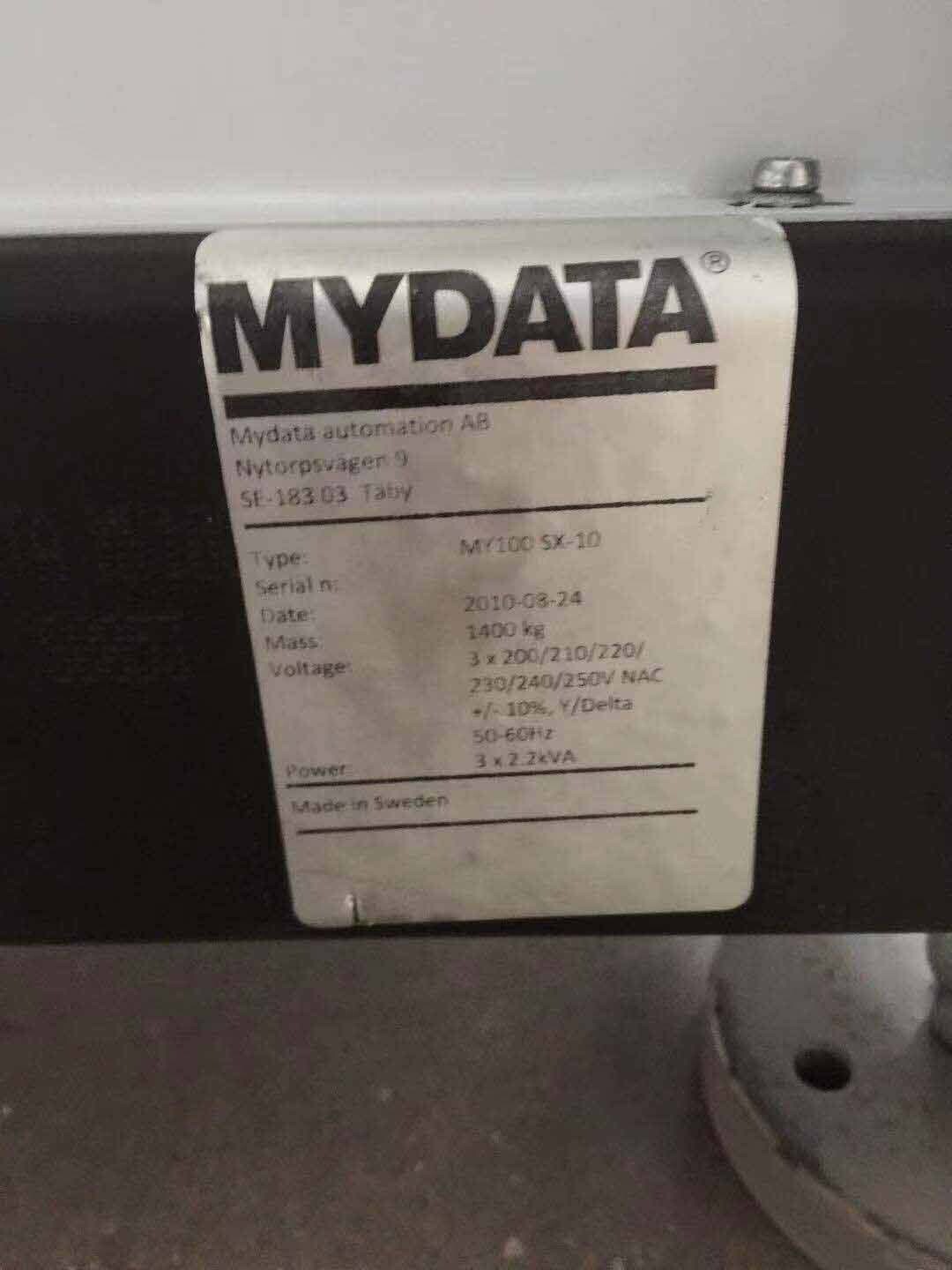

Used MYDATA MY 100SX-10 #9412544 for sale

URL successfully copied!

Tap to zoom

ID: 9412544

Vintage: 2010

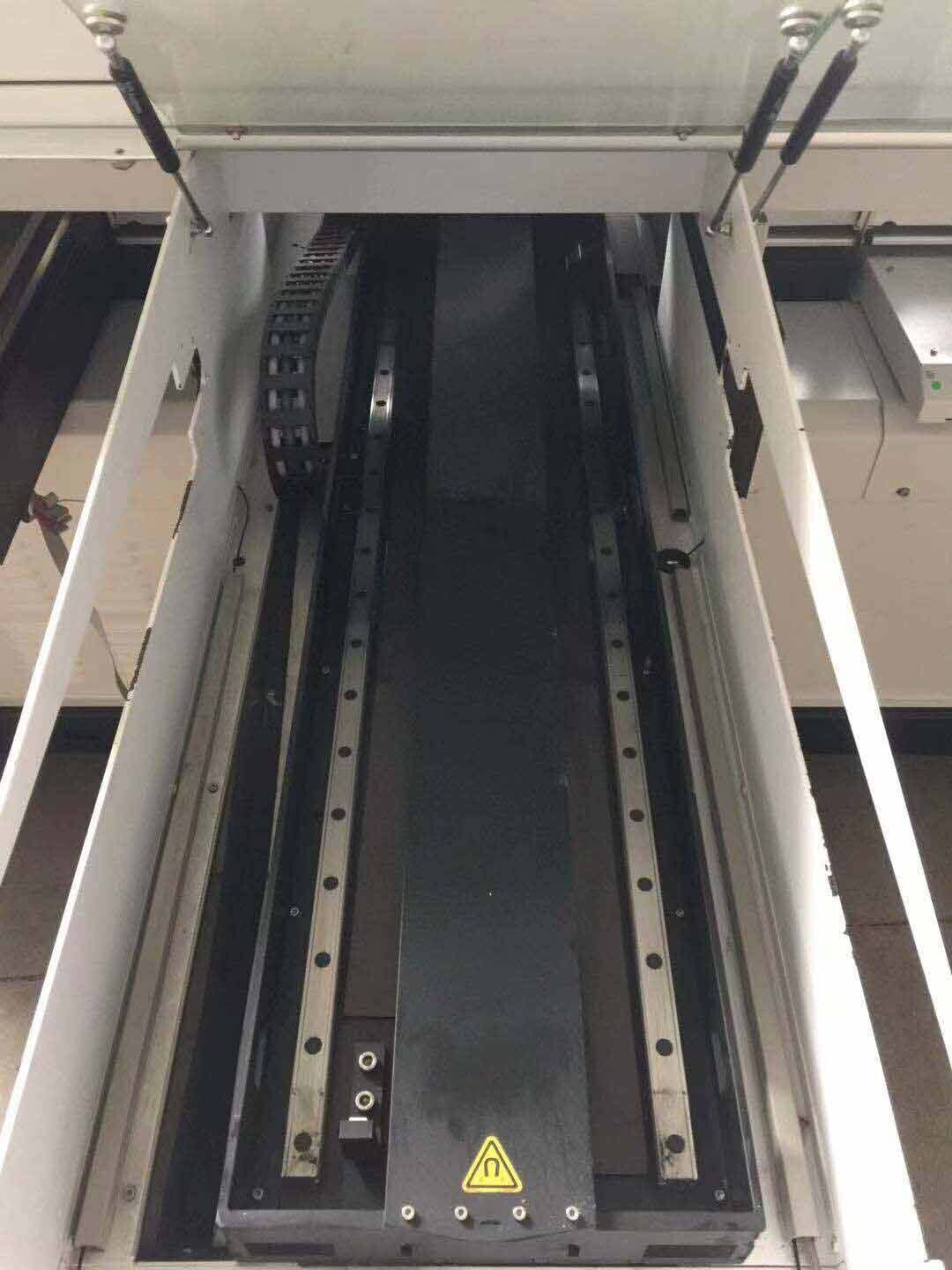

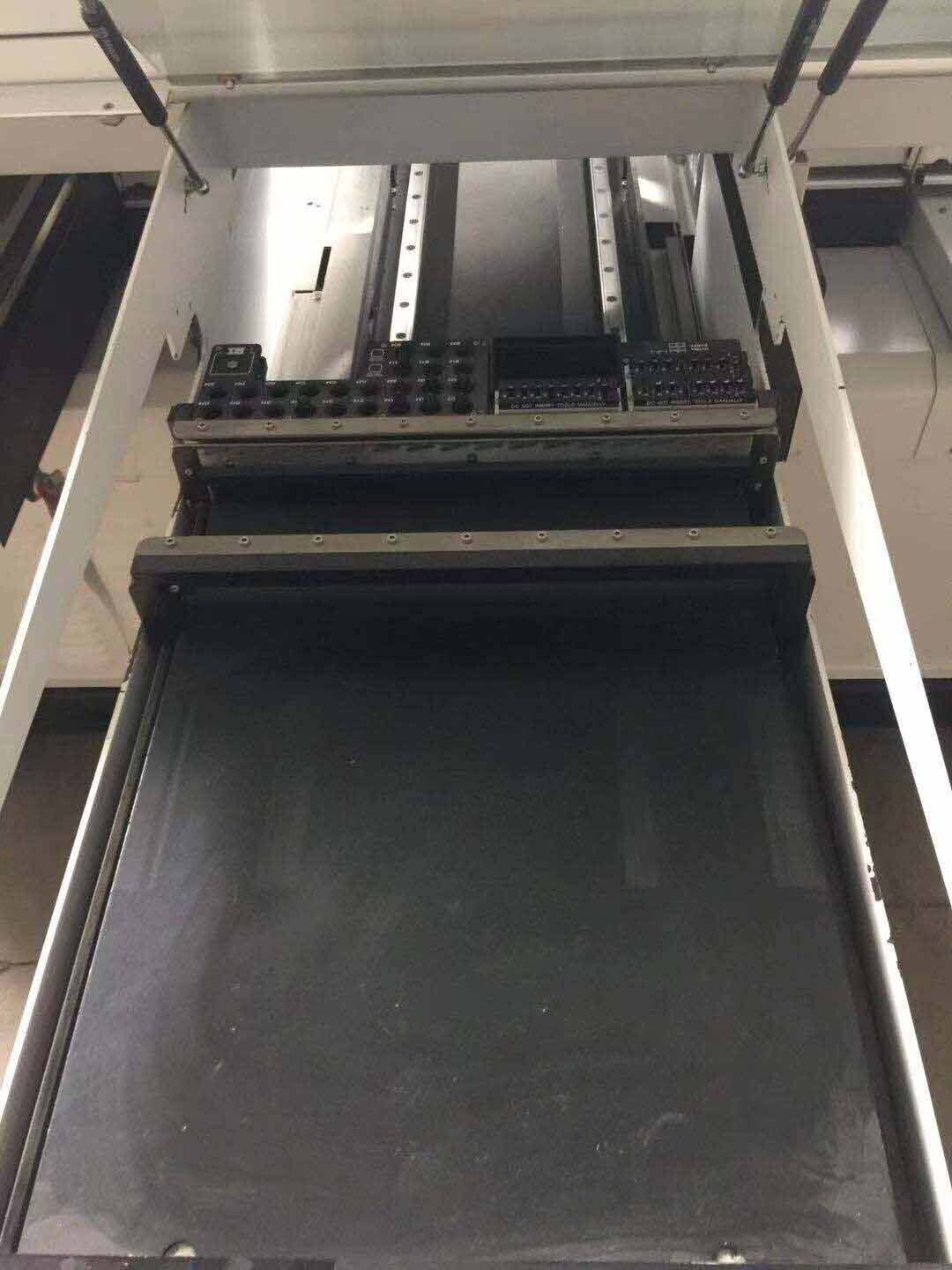

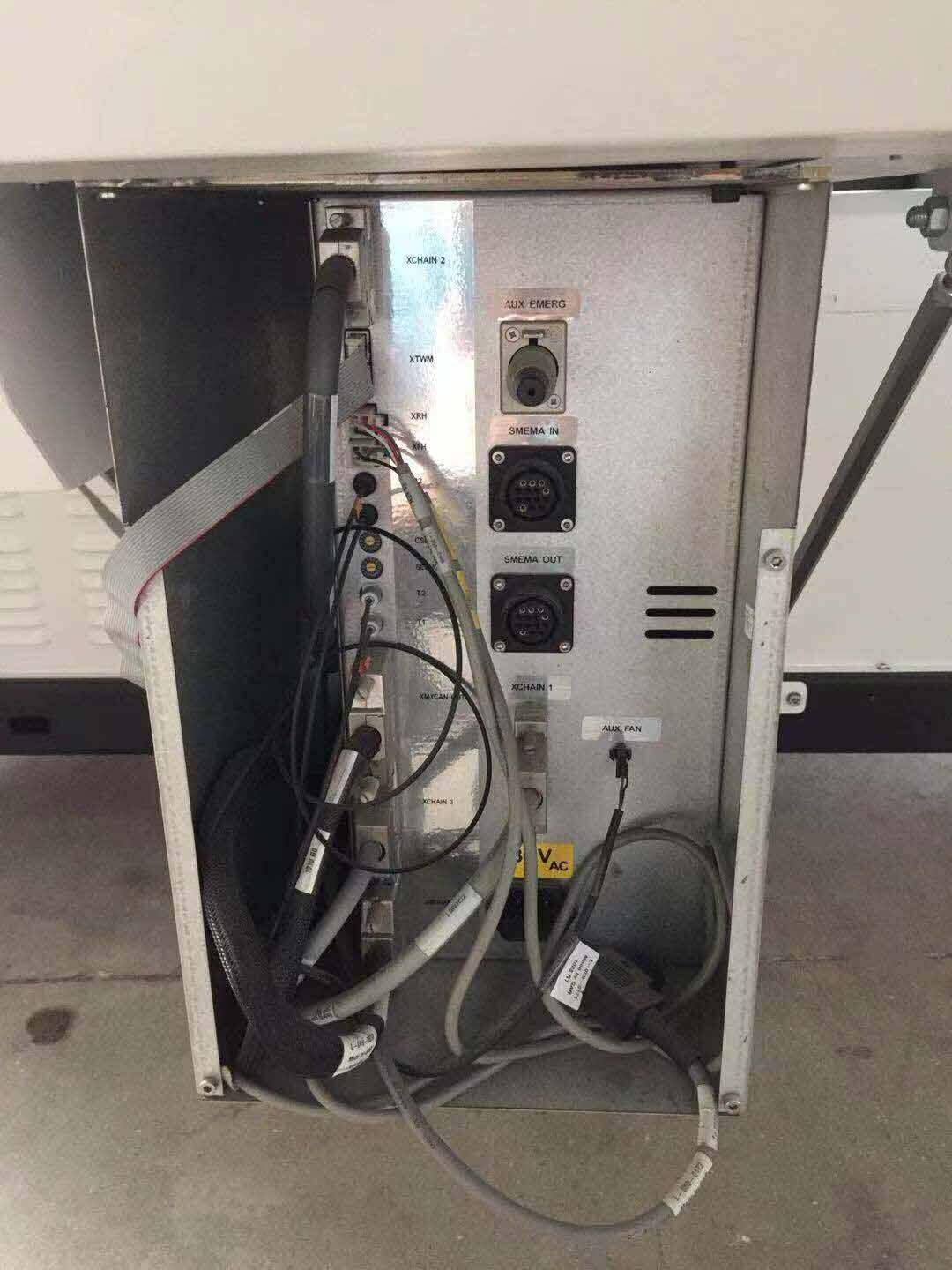

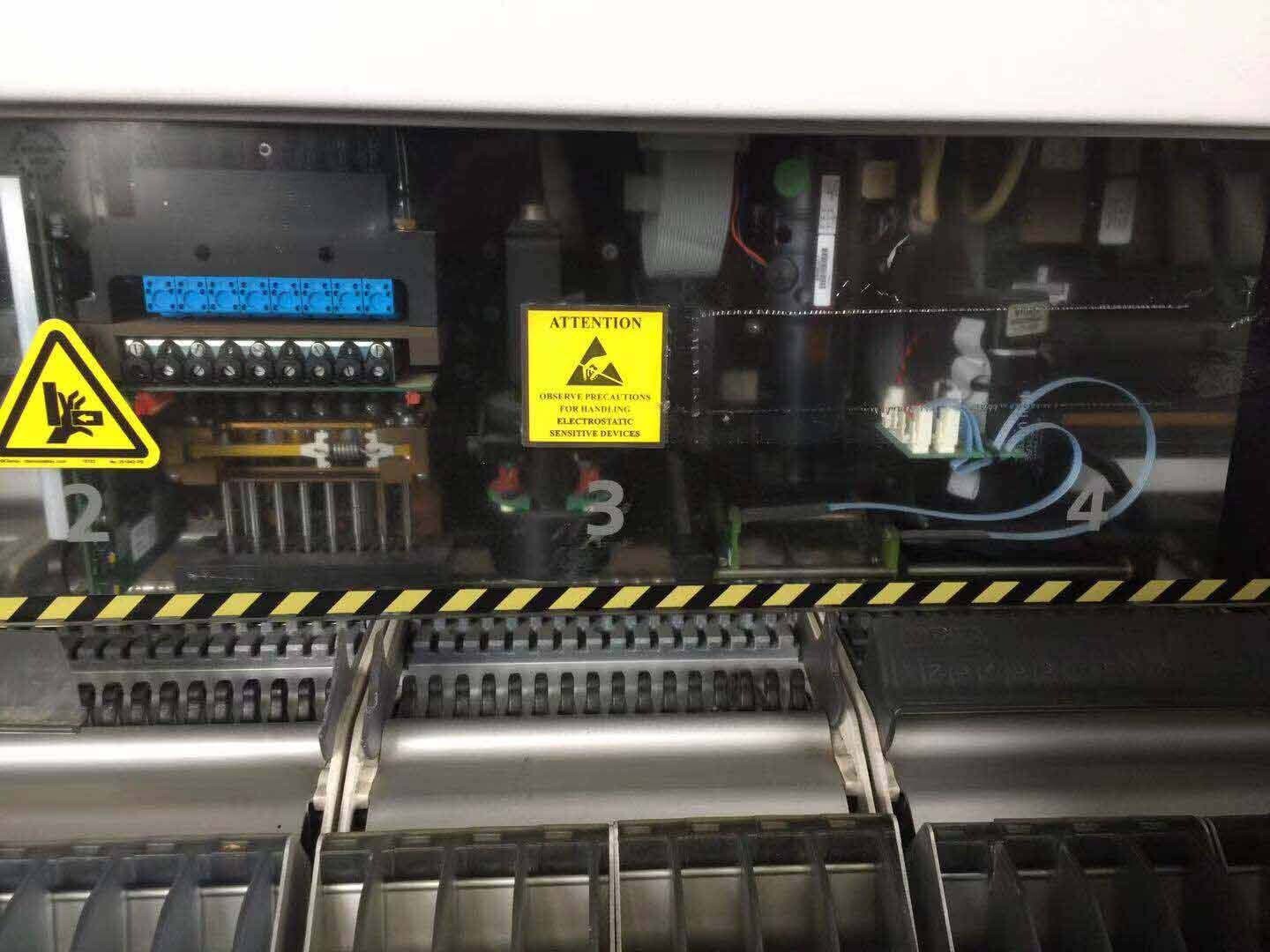

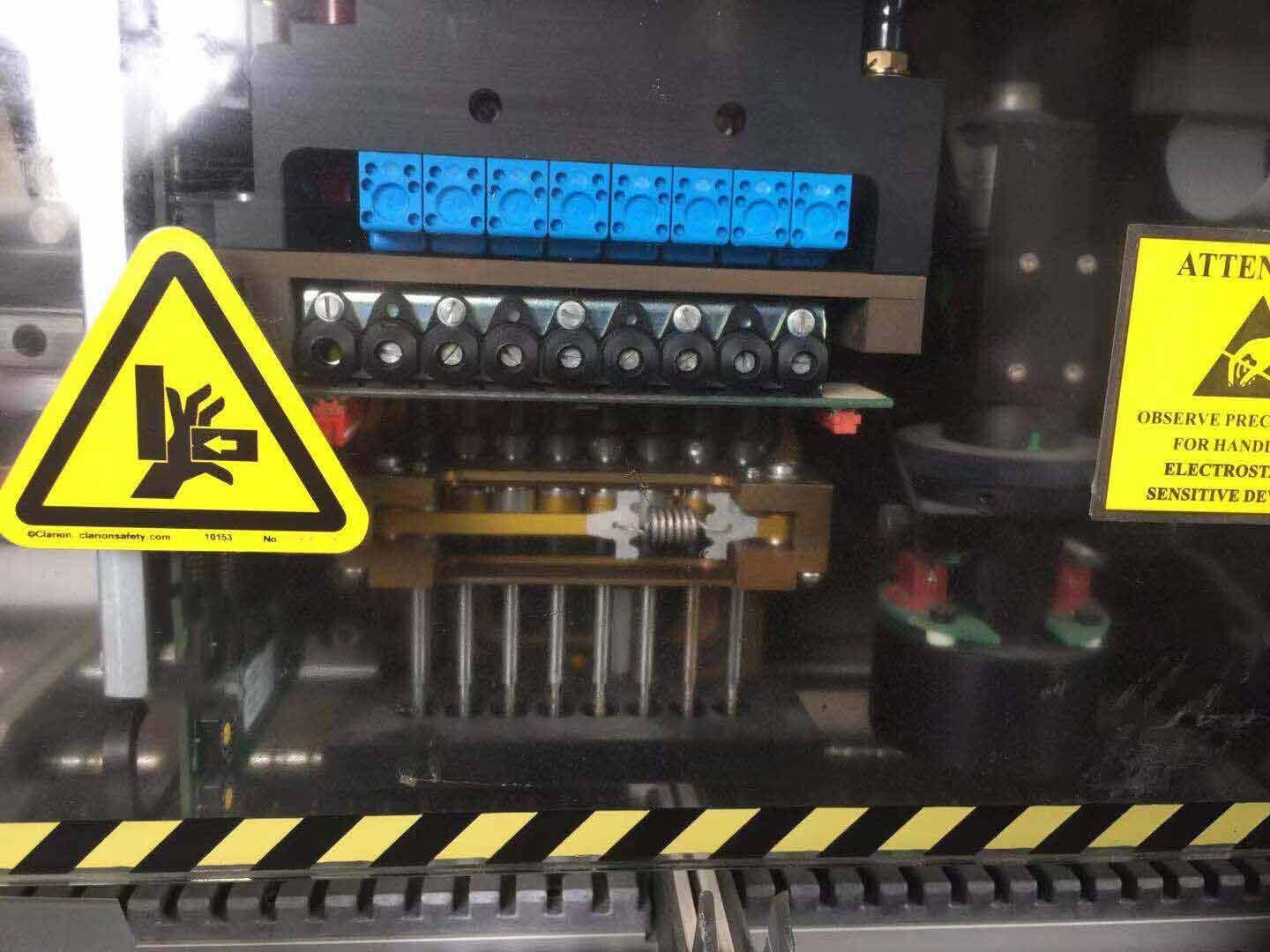

Pick and place machine

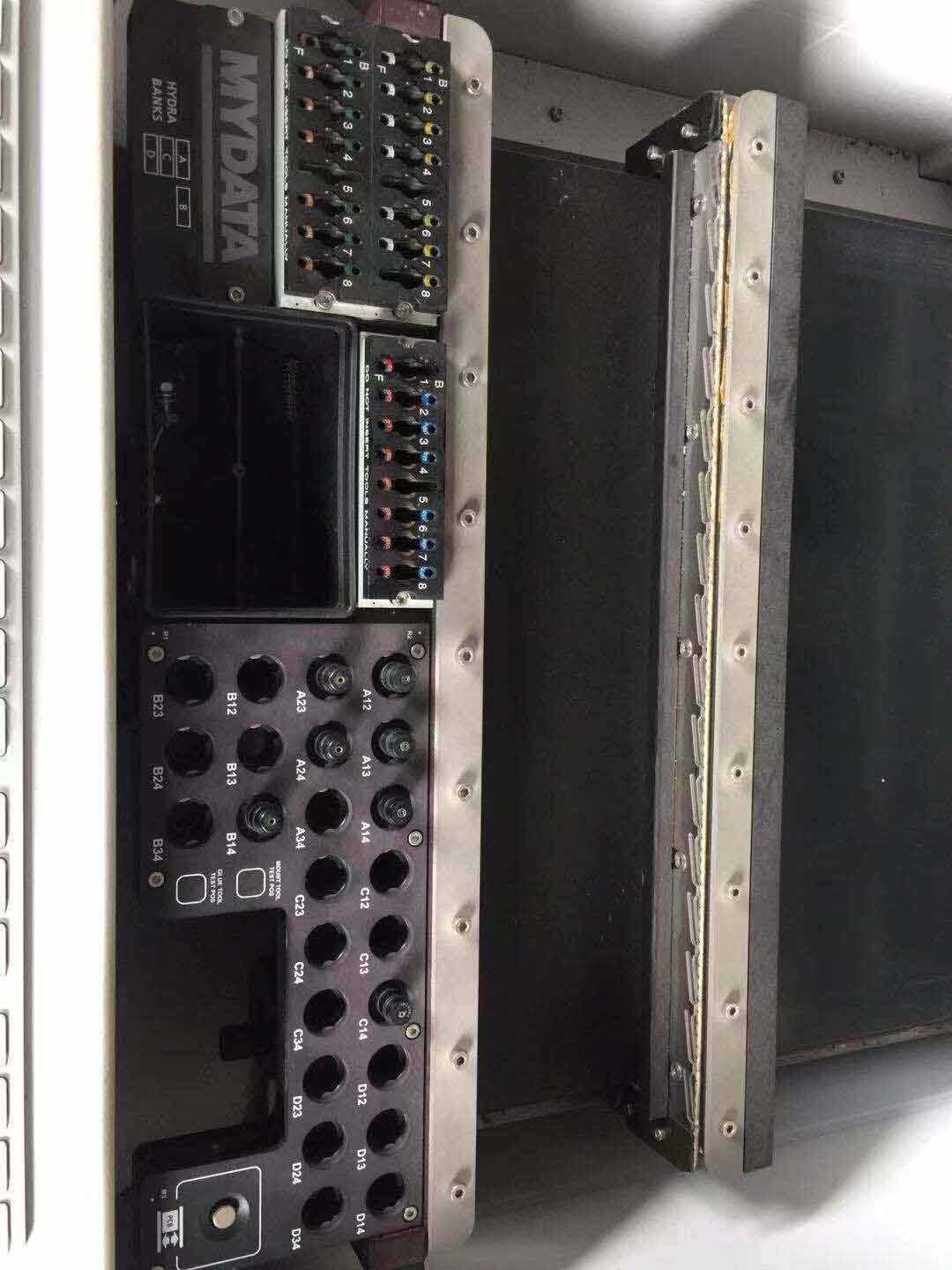

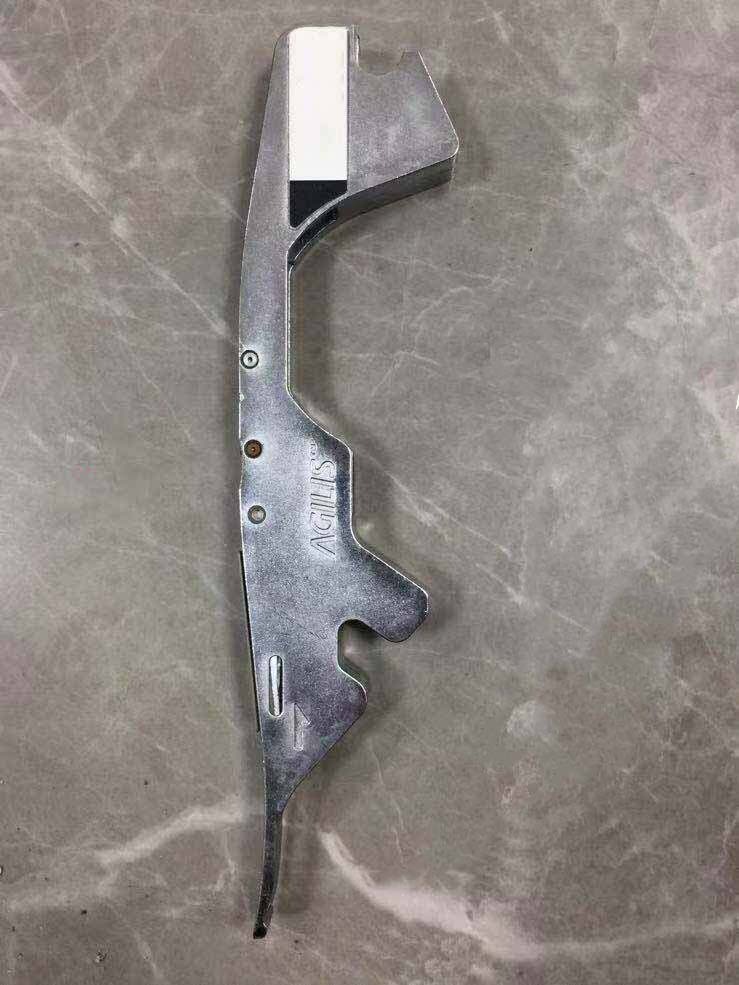

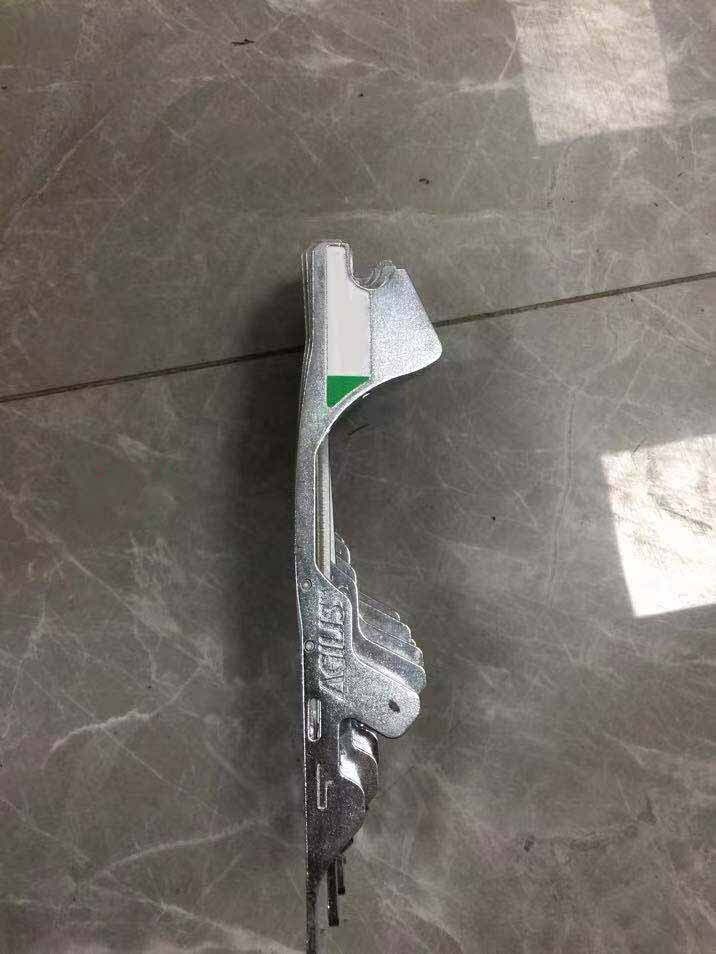

(15) 8.5 feeders

(36) 4.7 feeders

(3) 4.0 feeders

(6) 3.7 feeders

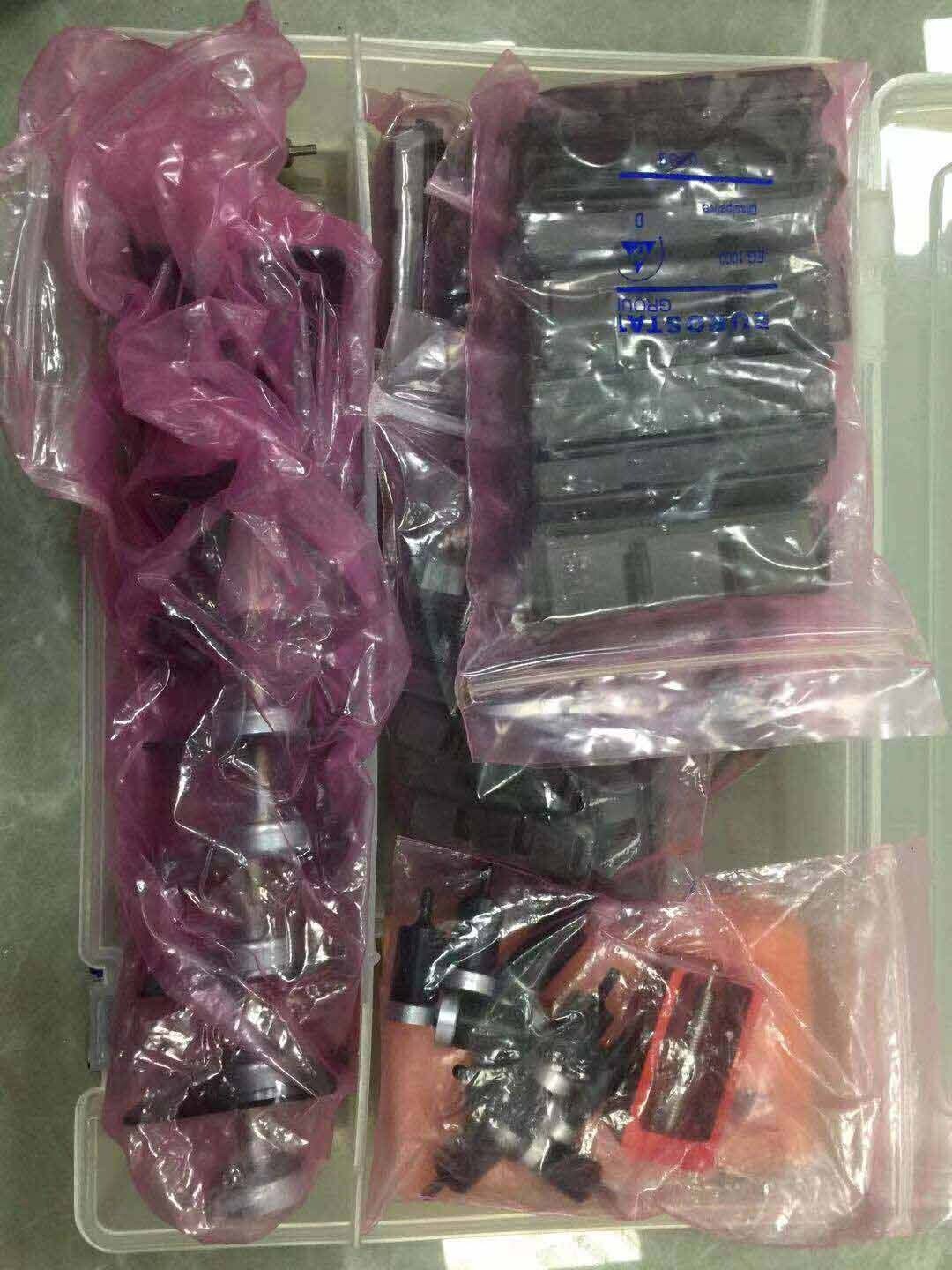

(5) Magazines

5.4 feeder

Fixed tray

2010 vintage.

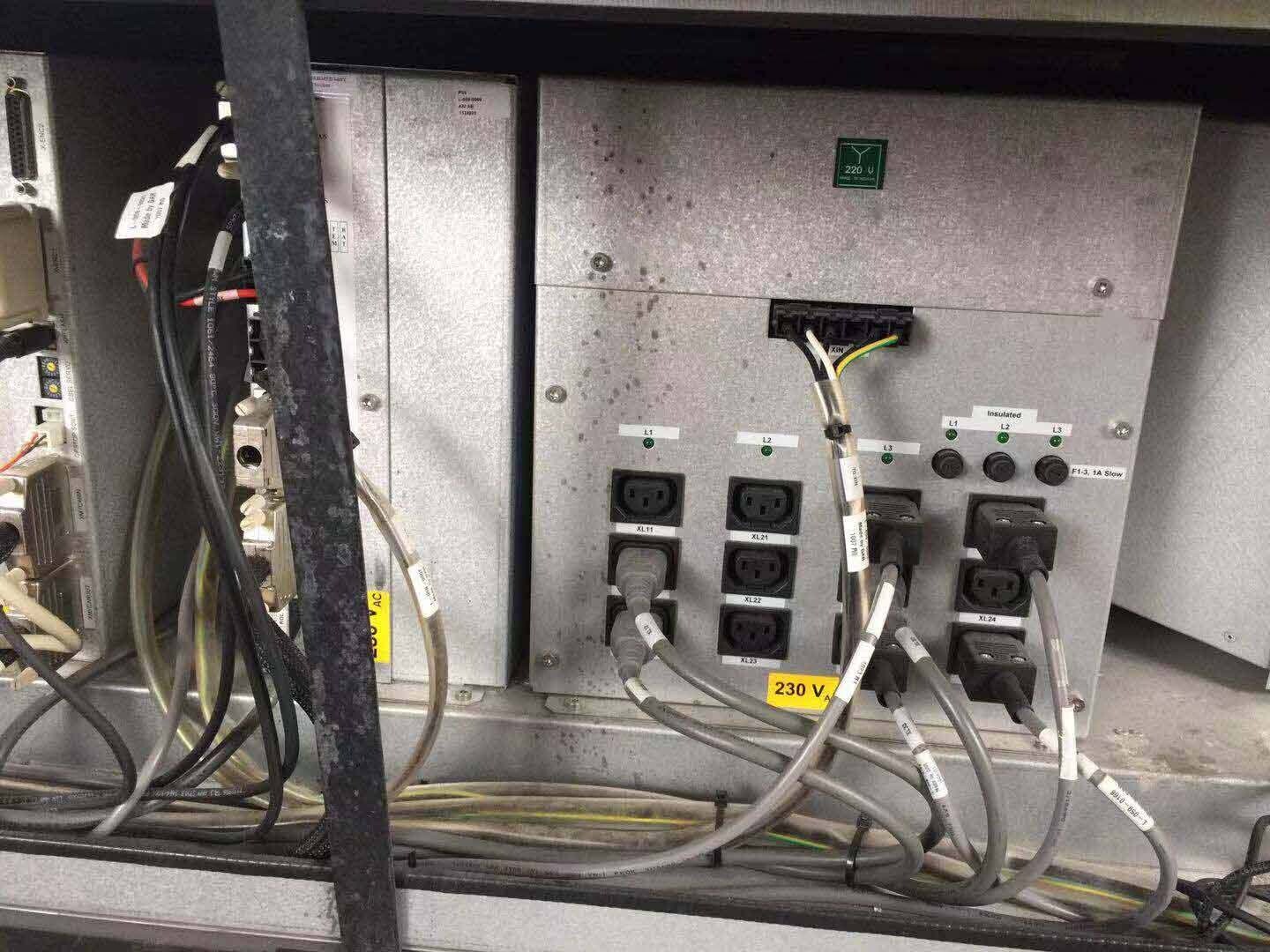

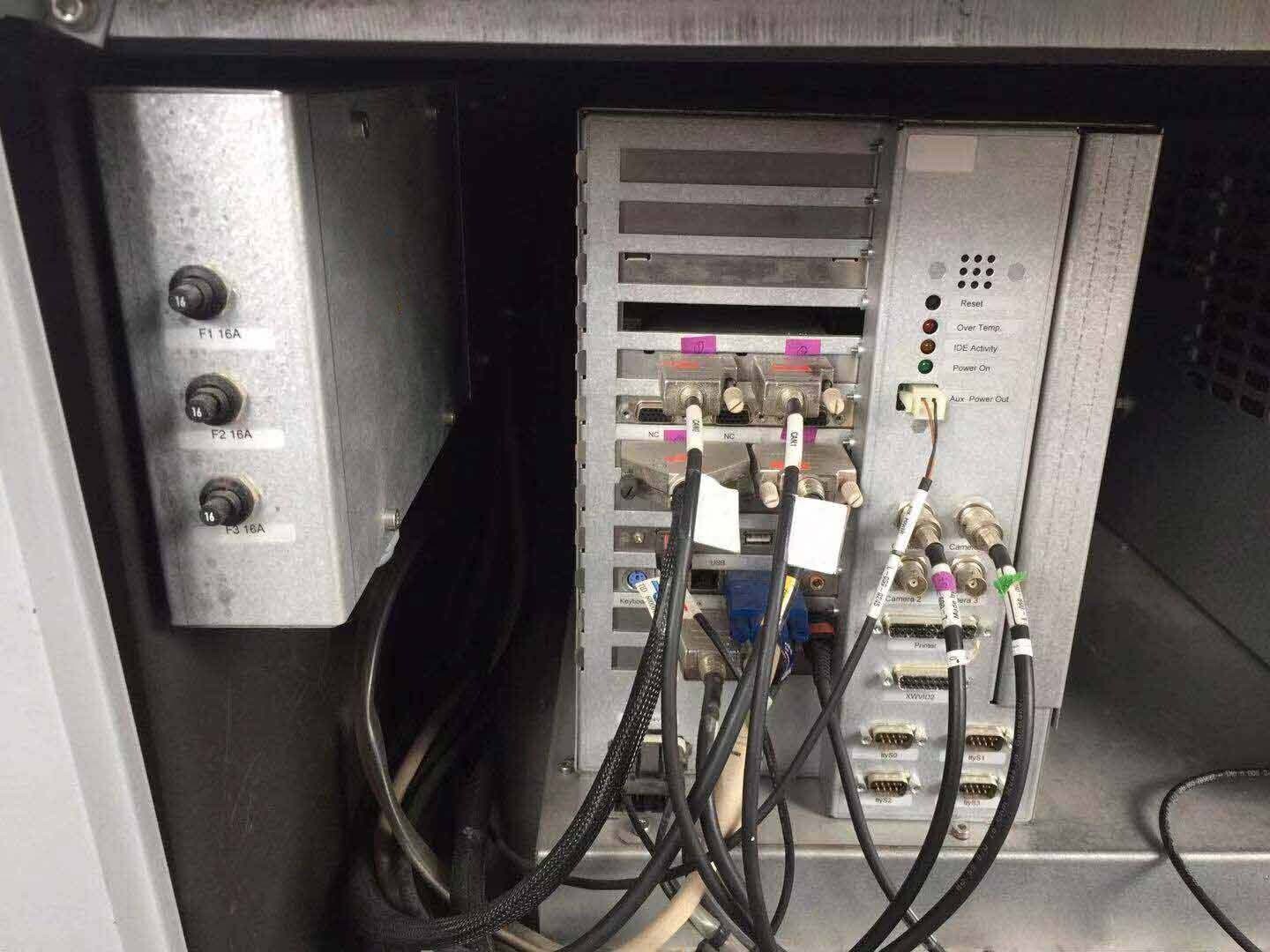

MYDATA MY 100SX-10 is a powerful and versatile pc board assembly and manufacturing equipment that can be used to boost manufacturing efficiency. It comes with a load of features and options that give users the flexibility to craft various designs to suit their intent. With this system, users can quickly assemble, customize, and test a wide range of circuit board assemblies (CBAs). MYDATA MY100-SX-10 includes a feeder unit that can accommodate up to a hundred components. This allows different type of components to be fed into the machine for assembly, such as resistors, capacitors, diodes, transistors, and other chip components. The machine also has a custom designed software that provides detailed information on the components and the intended circuit design, as well as the ability to customize the sequence of the process. The tool is equipped with five placement heads that move simultaneously along an X, Y, and Z-axis, enabling accurate placement of components from different sources. Additionally, it comes with a monitoring asset that monitors the progress of the automated process and logs any error that might occur, providing a detailed report for debugging or review. When it comes to PCB assembly and testing, MY 100 SX-10 can quickly test for continuity, shorts, and open circuits. Furthermore, it carries out thorough inspection of the assembled boards, ensuring their compliance with industry standards and customer requirements. To ensure the quality of the assembled board, MY100-SX-10 has a path optimizing feature that can minimize potential risks and minimize the cost of production. The optimized travel path ensures that each assembly step is completed before starting the next, thereby maximizing output speed and accuracy. In conclusion, the MY DATA MY 100SX-10 is a powerful and versatile automated PCB assembly and manufacturing model that provide users with a comprehensive solution for their circuit board assembly and manufacturing needs. It has a load of features that are designed to help users quickly assemble, customize and test a wide range of circuit board assemblies. Moreover, its monitoring equipment helps users to identify and correct any errors that might occur during the process, giving accurate and real-time results.

There are no reviews yet