Used MYDATA MY 500 #293664679 for sale

URL successfully copied!

Tap to zoom

ID: 293664679

Vintage: 2014

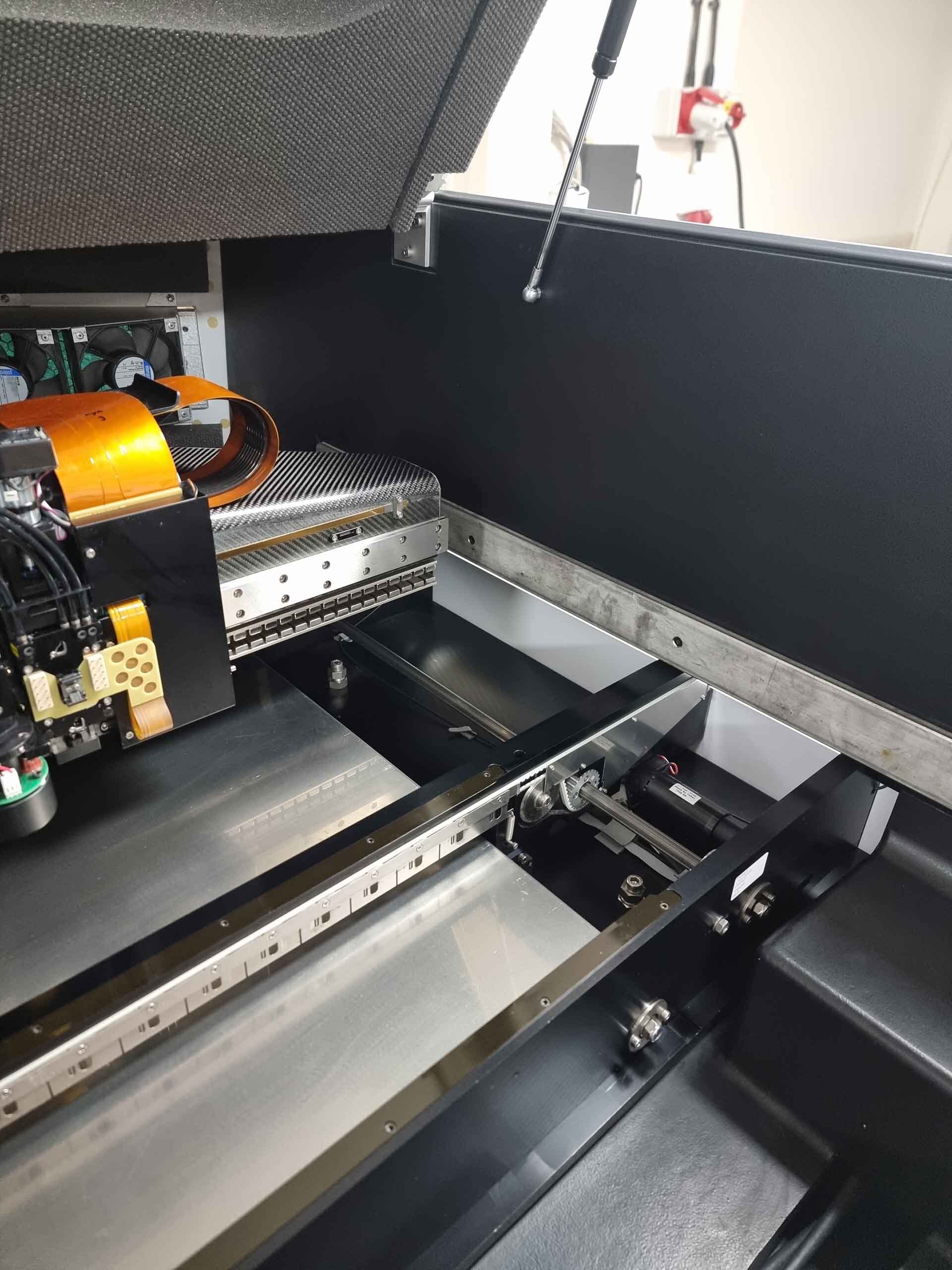

Jet solder paste printer

Running hours: 2,810

Rated speed (cph equivalent): 30,000 cph

Reference board throughput : 28,000 cph

Single dot repeatability 3s (X, Y): 54 μm

Single dot accuracy @ Cpk=1.33 (X, Y): 80 μm

Deposit accuracy @ Cpk=1.33 (X, Y) QFP100C: 33 μm

Deposit accuracy @ Cpk=1.33 (X, Y) 0603: 40 μm

Deposit repeatability 3s (X, Y) QFP100C: 19 μm

Deposit repeatability 3s (X, Y) 0603: 24 μm

Dot range:

Minimum dot diameter: 0.33 mm (0.013")

Maximum dot diameter: 0.47 mm (0.019")

Minimum dot volume: 5 nl

Maximum dot volume: 15 nl

Single dot volume repeatability (5 nl dots): 12%

Single dot volume repeatability (15 nl dots): 8%

Deposit volume repeatability, QFP100C: 4.0%

Deposit volume repeatability, 0603: 3.5%

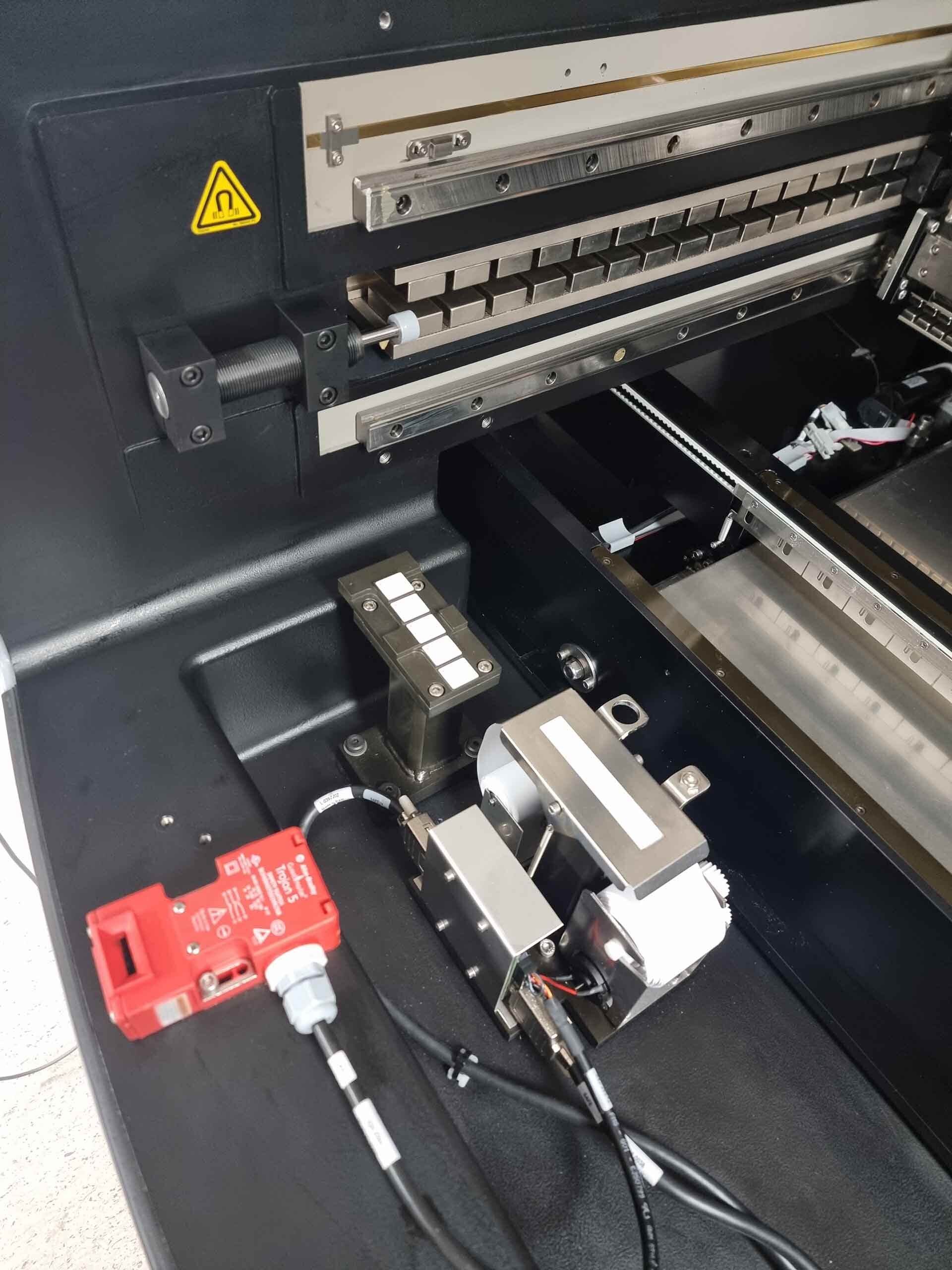

Board handling:

Maximum board size: 508 x 508 mm (20" x 20")

Minimum board size: 70 x 50 mm (2.7" x 2")

Board thickness range: 0.4 - 6.0 mm (0.016"- 0.24")

Board edge clearance, top: 3 mm (0.12")

Board edge clearance, bottom: 4 mm (0.16")

Bottom side clearance 20 mm (0.79")

Max board warp / bow / twist: ±2 mm (0.08")

Max board weight: 5 kg (11 lbs)

Board transport height: Conforms to SMEMA standard for conveyor height

Height adjustable from 880-975 mm (34.6"- 38.4")

Operation mode: Inline, manual, inline odd-board, right-to-left, left-to-right

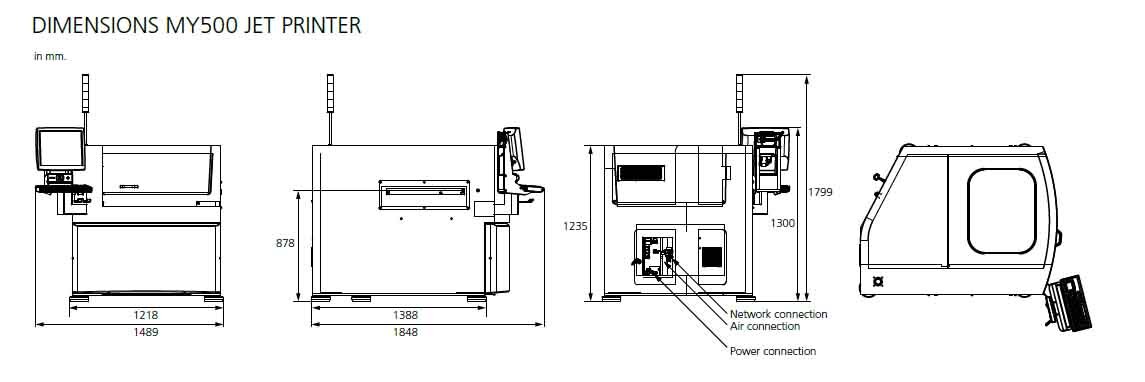

Power requirements: Single phase, AC 1700 VA

Power consumption: 1200 W

Voltage: 200-240V, ±10%, 50/60 Hz (100-120V ±10%, 50/60 Hz)

Air supply: 6 bar, 250 l/min

Ambient temperature: +18°C to +30°C, 30-80% RH non-condensing

2014 vintage.

MYDATA MY 500 is a pc board assembly and manufacturing equipment designed to provide reliable and efficient electronic production. It features two independent boards of processing power: one for managing and controlling all feeder, conveyor, placement, and injection moulding processes, and a second for coordinating production with advanced software functionality. MYDATA MY500 has the capability to pick and place components from 0603 up to 88x43mm in size, with a master feeder size of up to 8mm. It also features an integrated board edge conveyor for moving standard board sizes from half to full size. This conveyor eliminates the need for manual operation and offers a system that can be used to manufacture electronics quickly and efficiently. MY 500 also features a multitude of other features and components, such as a built-in generator and printer for producing clear, clean labels; heated and cooled drying stations; and an integrated nozzle taping unit for loading reels of components. Its injection moulding machine makes it the perfect companion for quickly producing parts, including components with complex geometries. MY500 is designed for both production and prototyping requirements, and it has the ability to accept pass/fail signals from external test systems. Its built-in components and software functionality are highly reliable and offer the users maximum flexibility and deep control over their production processes. MYDATA MY 500 provides an advanced user interface and is continuously expandable. It can be tailored for local production requirements and built upon aftermarket kit expansions, which makes it a highly capable and versatile pc board assembly and manufacturing tool. Overall, MYDATA MY500 provides a powerful and efficient solution for electronic production. It features an array of advanced components and software functionality for controlling and managing all stages of the production process, and its integrated printer and nozzle taping asset make it a comprehensive solution for a variety of production needs.

There are no reviews yet