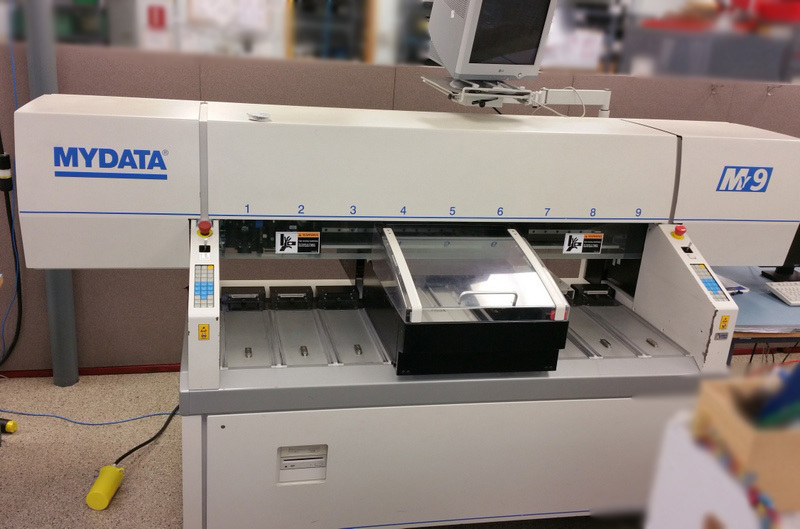

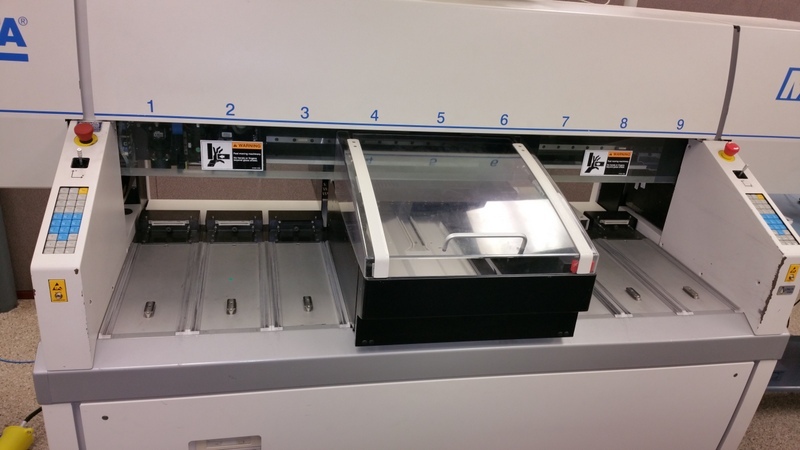

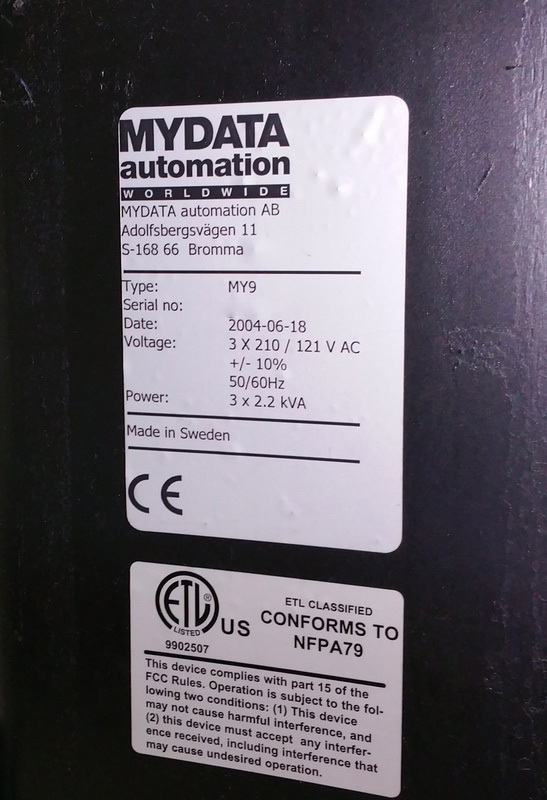

Used MYDATA MY 9 #9171132 for sale

URL successfully copied!

Tap to zoom

ID: 9171132

Vintage: 2004

Pick and place machine

With Agilis

No feeders

Options active:

Electrical two-pole test

Electrical transistor test

Optical centering

Shared databases

Hydra

Z high speed

Autoteach

Linescan for Z

MYSpeed

Software:

TPSys by MYDATA Automation

Version 2.4.6b (2.4+) for Linux

System statistics:

Total up time: 105d 13h 52m 19s

Total assembly time: 27d 2h 93 25s

Total glue time: ---

Total mounted with Z: 729393

Total Glued: 0

Total HYDRA cycles: 355947

Tool 1

Mounted: 296136

Fail: 3082

Tool 2

Mounted: 258908

Fail: 2499

Tool 3

Mounted: 309994

Fail: 2783

Tool 4

Mounted: 302342

Fail: 2633

Tool 5

Mounted: 313301

Fail: 2341

Tool 6

Mounted: 314246

Fail: 2966

Tool 7

Mounted: 327786

Fail: 2814

Tool 8

Mounted: 205780

Fail: 2822

Total Mounted: 3057886

Total X cycles: 1085340

Currently installed

2004 vintage.

MYDATA MY 9 is a pc board assembly and manufacturing equipment that helps to streamline and automate the manufacturing and assembly processes of printed circuit boards (PCBs). Using the latest technology, this system ensures that the entire production process sequentially takes place in an uninterrupted fashion and minimizes errors due to human error. The main component of MYDATA MY9 is the advanced software, which consists of various modules to control the entire production process. The software includes features like Automatic Part Pick & Place (APPP), which allows for parts to be placed quickly and accurately on the PCB; Track & Trace (T&T), which offer up-to-date information about the production process and the current status of each board; and Refere! ncing, which maintains accurate and complete assembly records, which is then used for reporting and other statistical process control activities. The unit also includes a number of advanced features such as Automated Flux Dispensing, which ensures that the correct amount of flux is dispensed to each part or area of the board; Automated Opto-inspection which use high resolution cameras to identify components and identify missing components; and Automated Solder Paste Printing, which uses a robotics arm to precisely apply solder paste to designated areas of the PCB where components need to be placed. In addition, MY 9 also includes setup features which minimize setup time, including Programmable Moveable Object (PMO) which allows for faster and easier tooling changes, allowing for improved productivity when switching between jobs. Other setup features include Job Setup, which stores all the necessary settings and components needed in order to complete a particular job, and Vision Recognition, which integrates with PMO to identify components accurately and quickly. Furthermore, MY9 includes flexible production tracking features, so users can always track all production data such as time, production output, quality and other metrics. It also offers users with comprehensive statistical data analysis capabilities, which allow users to accurately analyse production performance and enable them to make necessary adjustments to improve productivity. In conclusion, MYDATA MY 9 is an advanced pc board assembly and manufacturing machine which has been designed to greatly reduce human errors and improve overall production and process efficiency. With its easy setup features, advanced automation and flexible statistical capabilities, MYDATA MY9 offers users a reliable and cost-effective solution for their PCB assembly and manufacturing needs.

There are no reviews yet