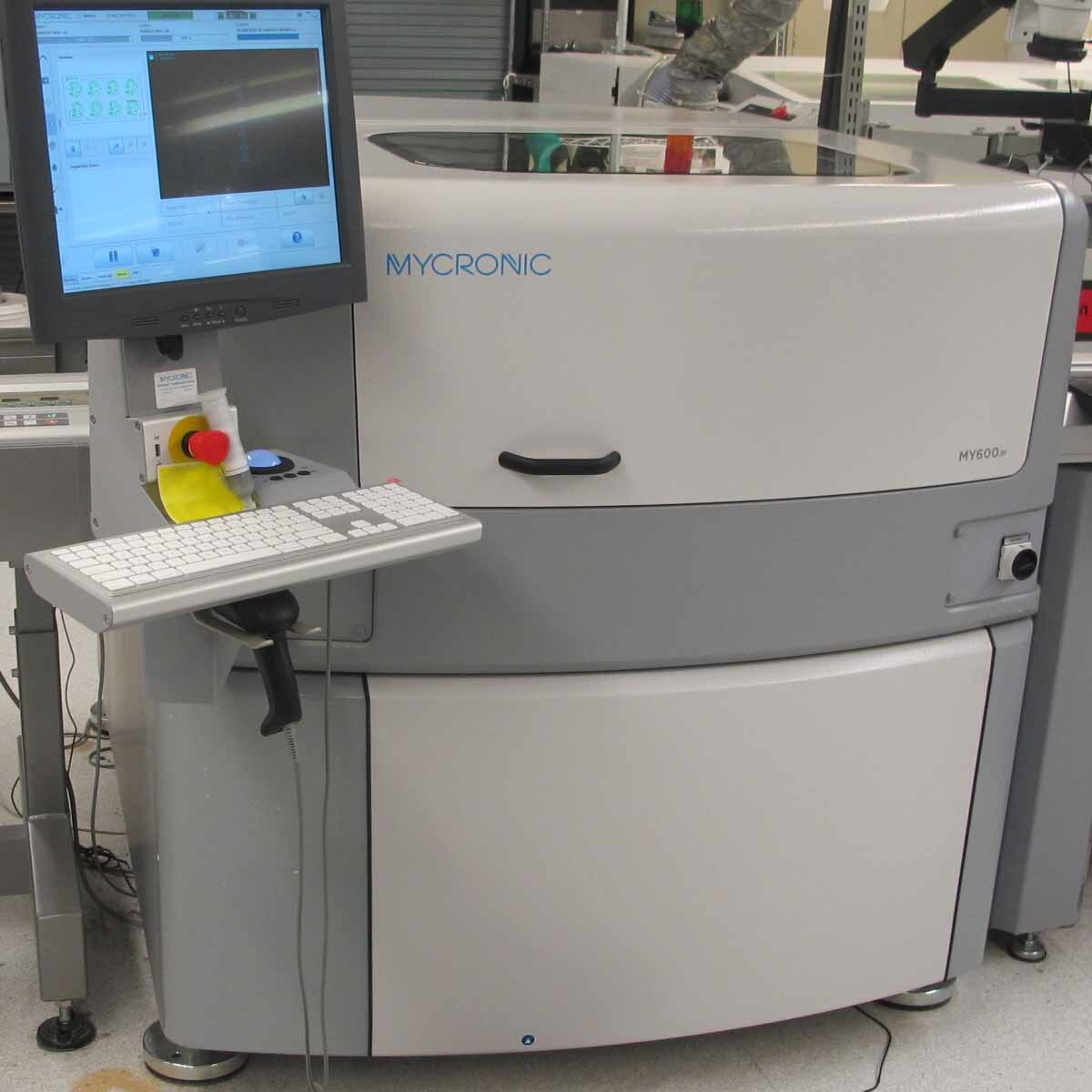

Used MYDATA / MYCRONIC MY 600 #293603111 for sale

URL successfully copied!

Tap to zoom

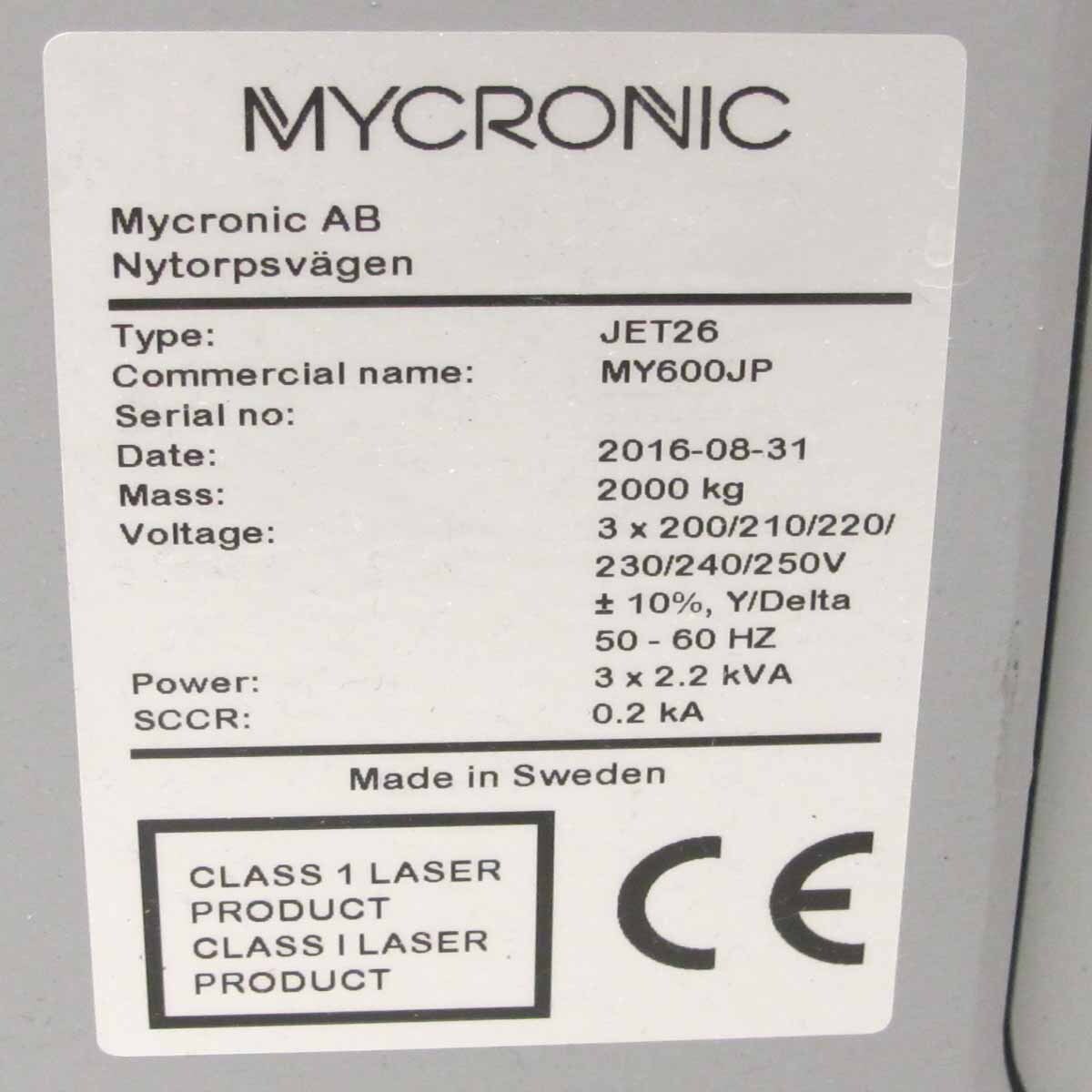

ID: 293603111

Vintage: 2016

Screen printer

Filter box

2D Camera

Network interface

Internal conveyor

Internal injector cooling unit

USB Barcode scanner

SMEMA Compliant

2D Inspection and repair

AG04 Ejector for solder paste

Manual syringe applicator

Jet printer: HERAEUS PD 205A Jet adhesive

PC with MYCAM JP for MY600

Power supply: 200-250 VAC, 50/60 Hz, 3 Phase

2016 vintage.

MYDATA / MYCRONIC MY 600 is a PC board assembly and manufacturing equipment designed to assist electronics and engineering professionals with the design, assembly, and manufacture of printed circuit board (PCB) components. With its popularity among engineers, MYDATA MY 600 is used in a variety of industries, including automotive, communication, home automation and medical. MYCRONIC MY 600 features a fully automated Pneumatic Flexible Fixture (PFF) system for precision hanging of boards for assembly and rework. The unit is capable of performing multiple processes on up to 12 different PCBs simultaneously. The machine is controlled with a high-performance PLC for efficient and reliable operation. The tool is compatible with most components, and can work with lead-free solder. MY 600 also features a 16-station pick-and-place platform, along with a SCARA-based motion asset. The PFF Model allows the user to rework even the most difficult through-hole components, as well as SMT and Micro BGA components. The placement rate is up to 10,000 products per hour and up to 0.5mm precision, allowing for accuracy at all times. The equipment also has a separate soldering station that utilizes selective soldering technology to ensure high-quality solder joints. MYDATA / MYCRONIC MY 600 also has three options that can be used to complete the soldering process, including a Thermotron-style soldering iron, a manual soldering iron and a MYDATA-style soldering paste. MYDATA MY 600 also features a SmartVision plating system, allowing for automated visual inspection of all components prior to assembly. This unit provides users with full, accurate information about the components, as well as real-time position tracking, allowing for increased accuracy and product reliability. In addition, the machine contains an integrated AOI interface that allows users to easily create recipes for each type of component, allowing for improved accuracy and efficiency. The AOI tool also performs real-time monitoring of components, and can detect problems with specific components, giving users the ability to resolve any issue quickly and efficiently. MYCRONIC MY 600 is designed to give users a flexible and reliable PC board assembly and manufacturing asset, to ensure quality and accuracy at every step of production. With its comprehensive feature set, MY 600 is sure to help engineers save time and increase productivity.

There are no reviews yet