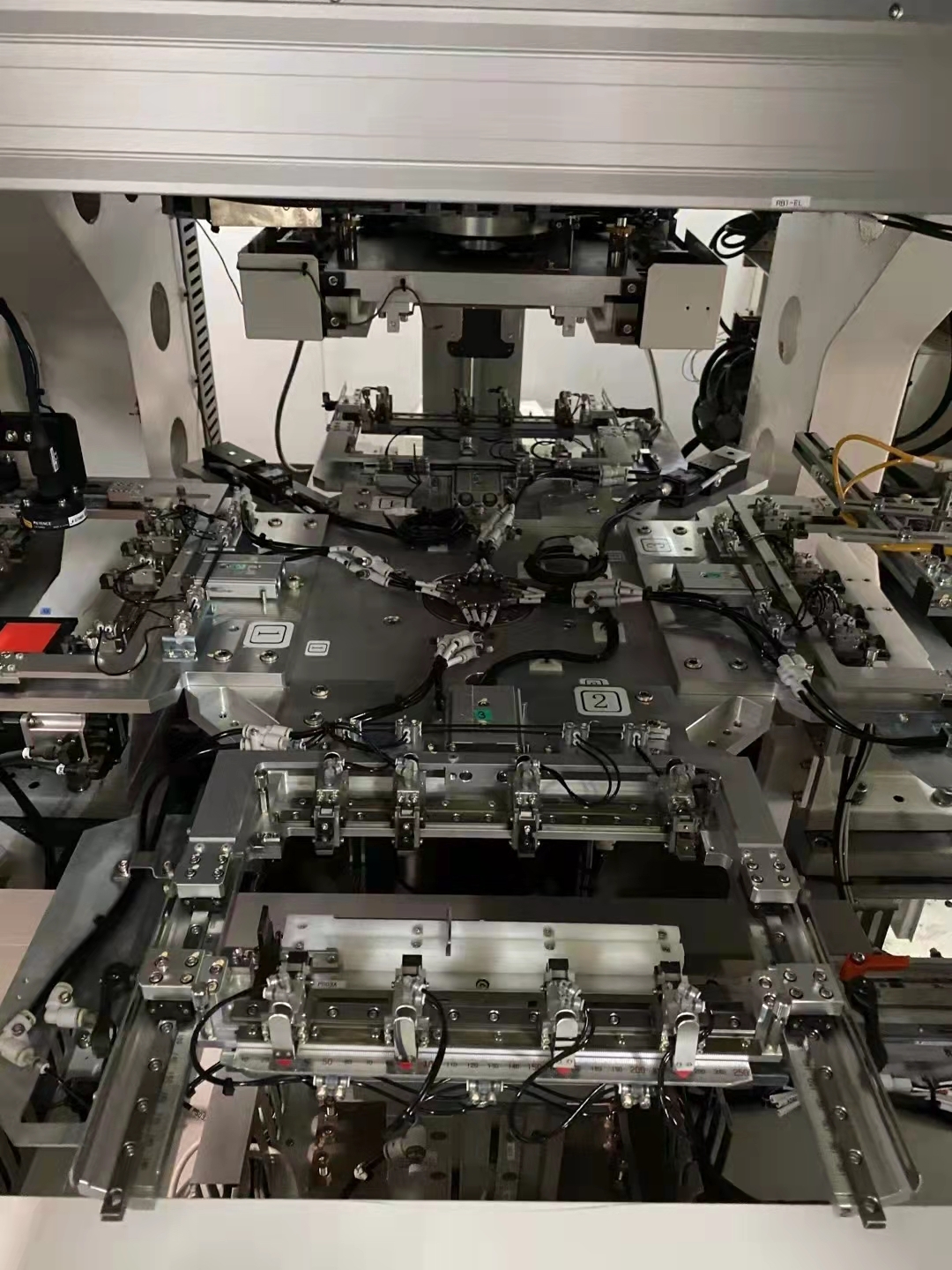

Used NIDEC READ Star Rec M6 II #293591841 for sale

URL successfully copied!

Tap to zoom

ID: 293591841

Open / Short inspection system

For PCB

16000 Pins

Tester: R5800

Black box

Work size:

X-Axis: 60mm to 260mm

Y-Axis: 45mm to 160mm

Manuals included

Power supply: AC 210 V, 3-Phase, 50 Hz, 4A.

NIDEC READ Star Rec M6 II is a pc board assembly and manufacturing equipment designed to produce high volumes of quality circuit boards. The system consists of a series of components that work together to create efficient and reliable device builds. This includes an advanced printed circuit board (PCB) handling unit, an automated pick-and-place machine, a surface mount technology (SMT) machine, and a reflow oven for soldering components. In addition, the tool is equipped with a variety of monitoring and diagnostics tools such as embedded vision inspection, defect detection and analysis, wet processing, and in-process testing. Star Rec M6 II was created to provide manufacturers with a faster and more efficient method of producing high-quality products. The asset is designed with advanced features such as high processing speed, precision control, and synchronized sub-assembly movements. Its components and processes work together to optimize accurate and repeatable device production. The advanced PCB handling model of the NIDECREAD NIDEC READ Star Rec M6 II is responsible for loading and unloading the device onto the conveyor. The automated pick-and-place equipment is then responsible for placing solder paste, components, and other parts onto the board. This is followed by the SMT system, which contains an Ultrasonic Nozzle Detection (UND) unit to ensure alignment and accuracy. Finally, the reflow oven is used to melt the solder paste so that the components are securely attached to the circuit board. In addition to this efficient device production machine, the NIDEC Star Rec M6 II also contains various monitoring and diagnostics systems. These include an embedded vision inspection tool, which automatically identifies defects on each board. Additionally, the asset is equipped with a defect detection and analysis model that can quickly identify issues in various stages of the production process. Other monitoring systems include wet processing, which captures images of early-stage process defects, and in-process testing that allows for real-time review of each board. NIDEC READ Star Rec M6 II is an efficient and reliable pc board assembly and manufacturing equipment. Its advanced PCB handling, pick-and-place system, SMT unit, and reflow oven all work together to produce high volumes of quality circuit boards. Additionally, the machine contains powerful monitoring and diagnostics tools that provide manufacturers with a complete production process solution.

There are no reviews yet