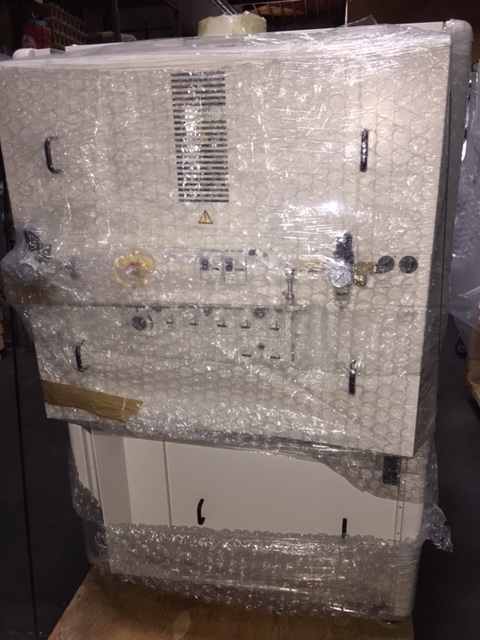

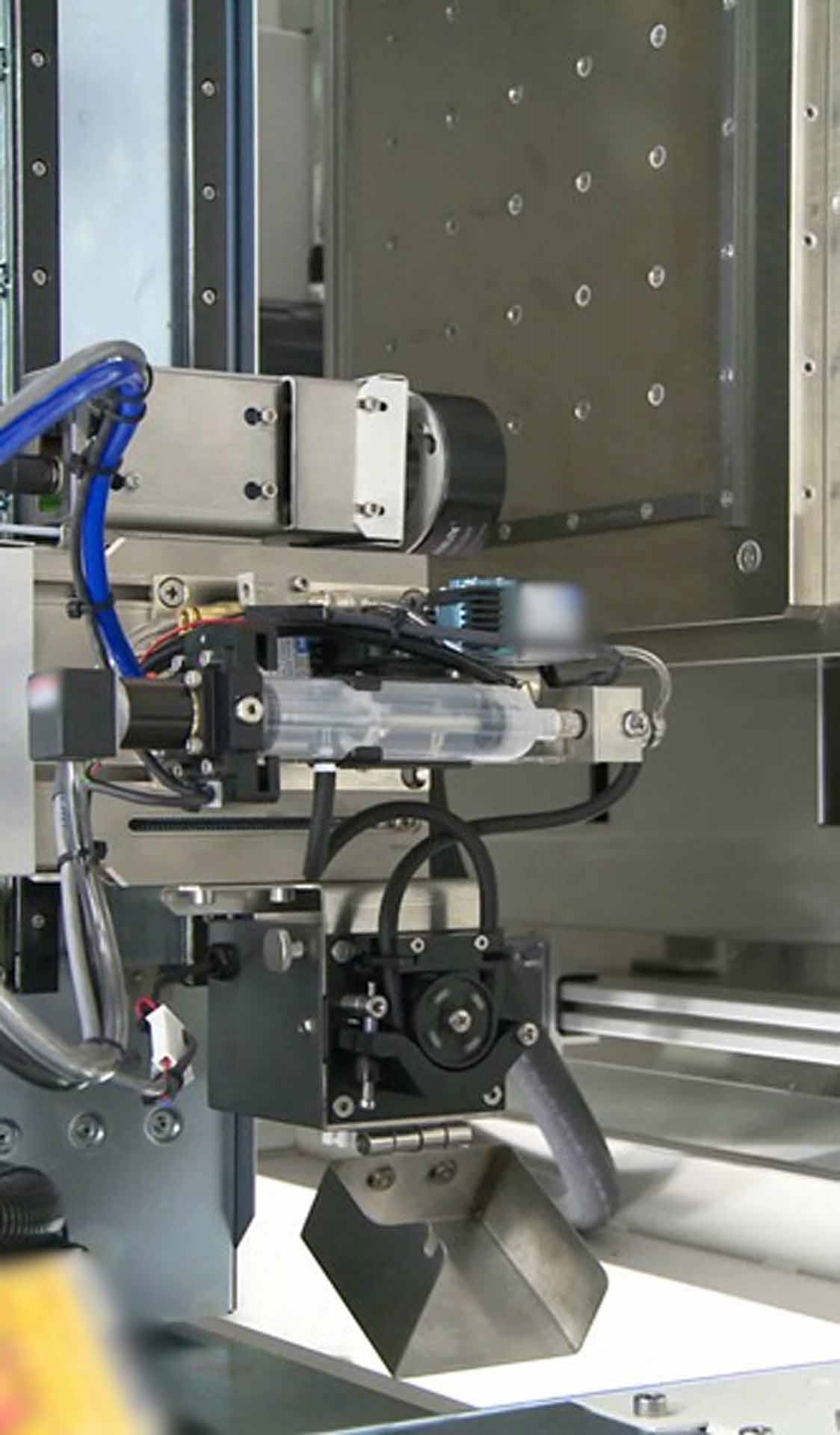

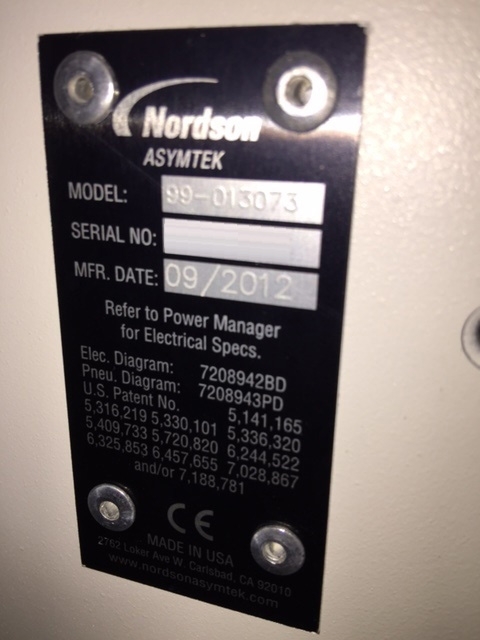

Used NORDSON / ASYMTEK S-820 #9186877 for sale

URL successfully copied!

Tap to zoom

ID: 9186877

Vintage: 2012

Dispenser

Model no: Special 99-013073

Qty / Part number / Description

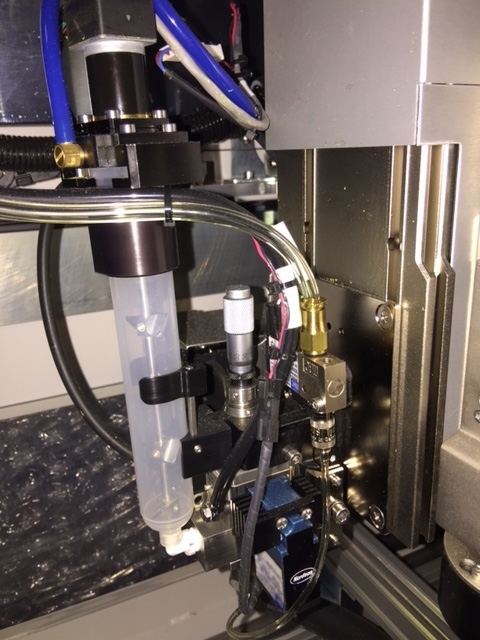

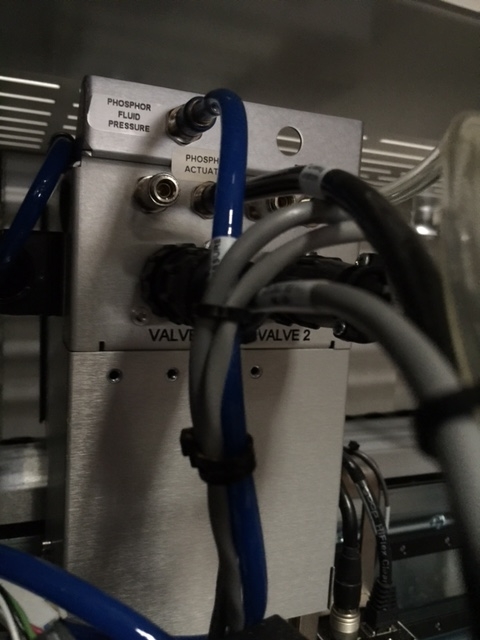

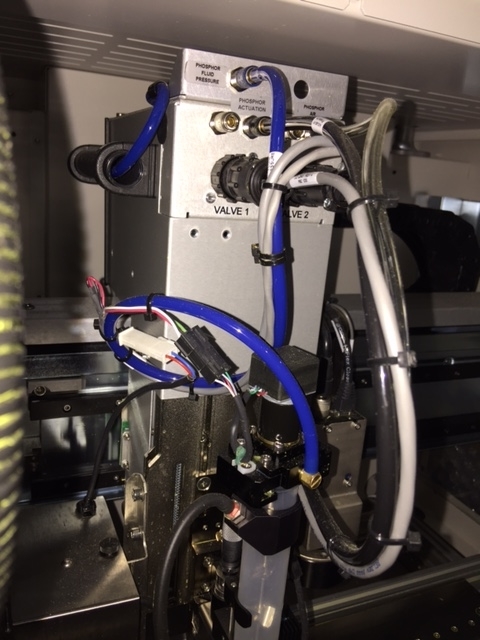

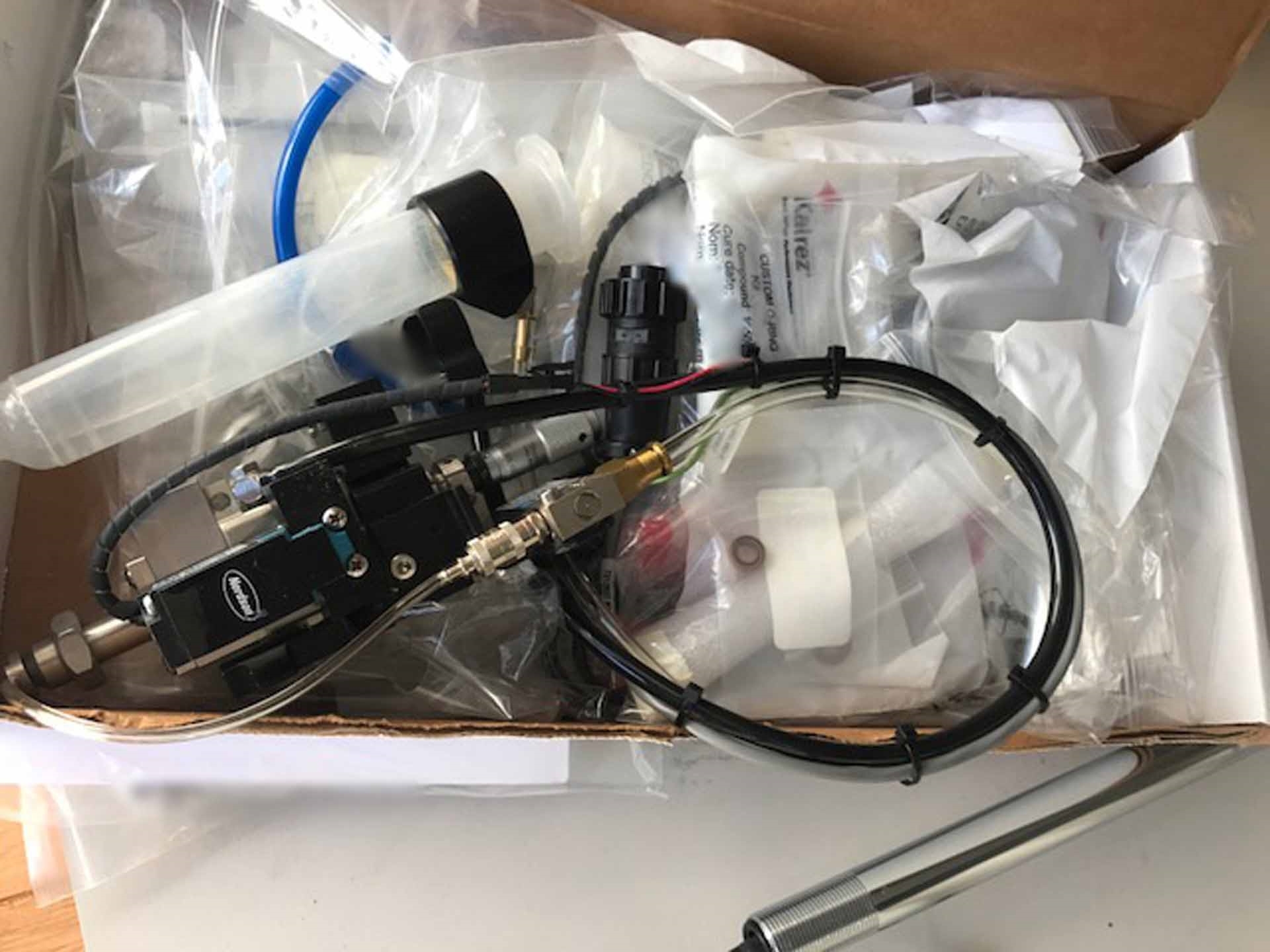

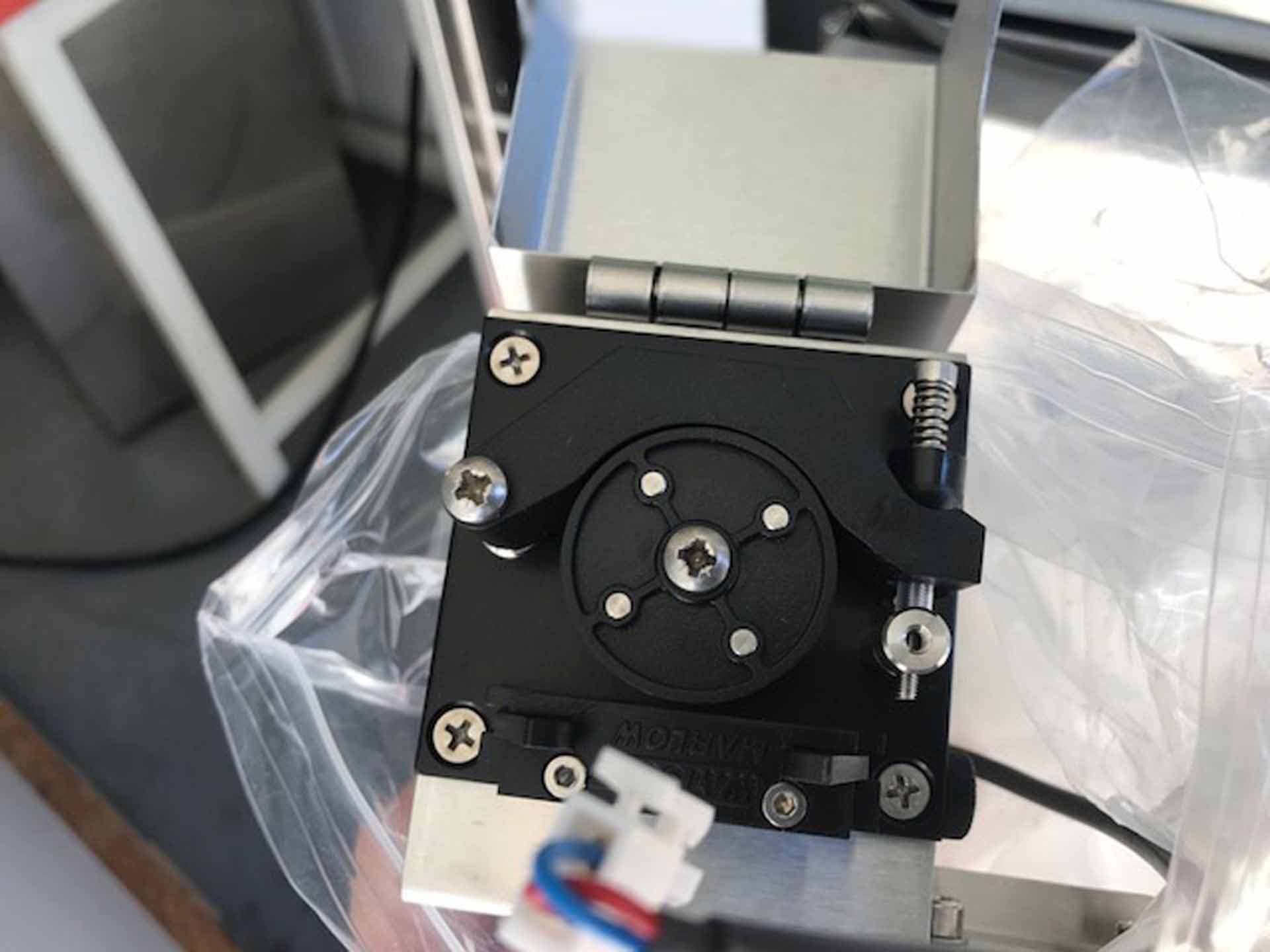

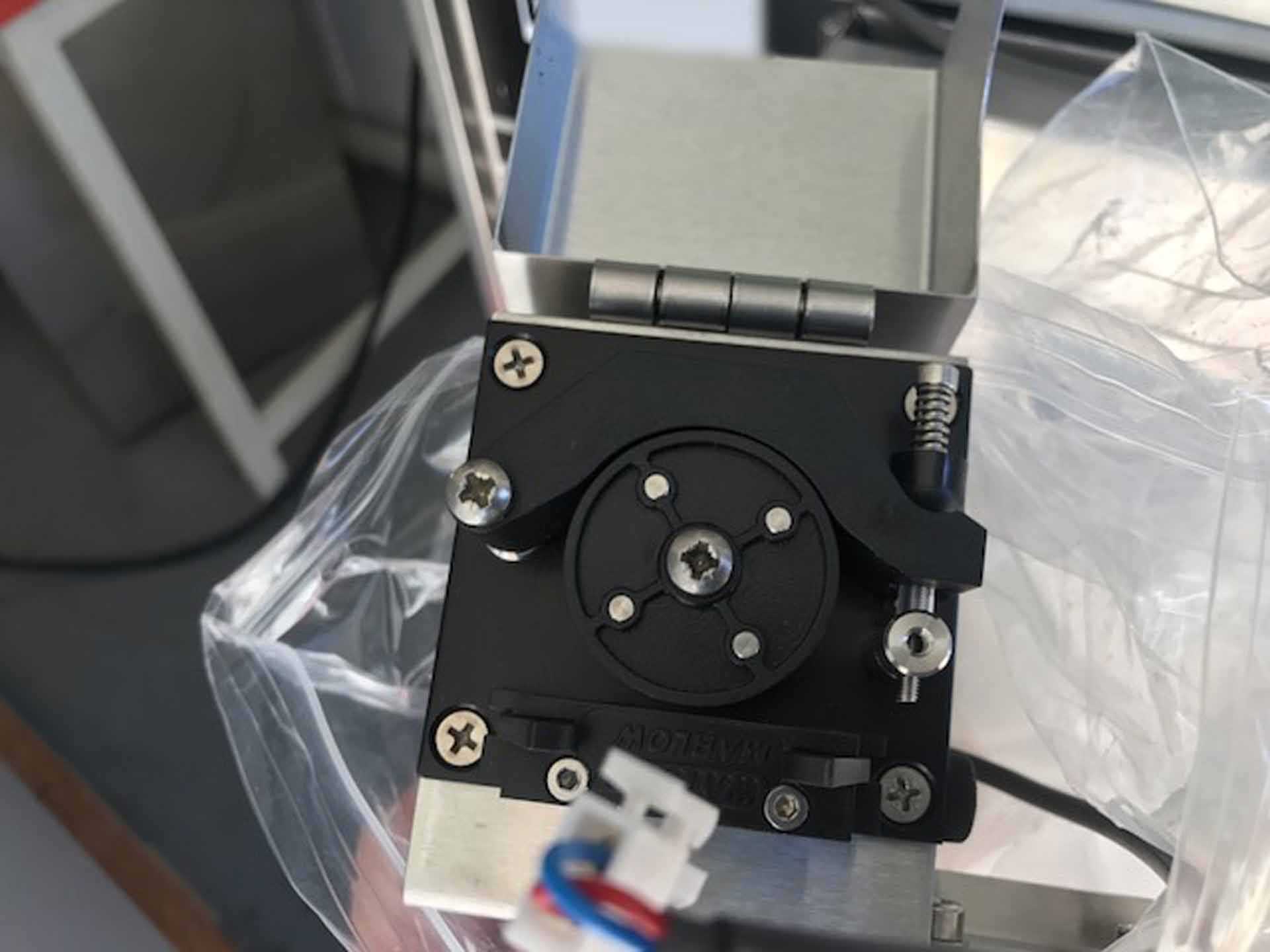

(2) / 99-013520 / Phosphor coating valves - DJ-22002

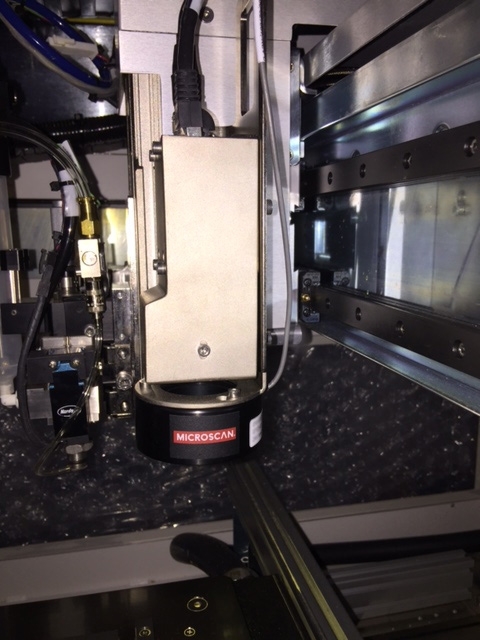

(1) / 99-015429 / Camera cover - phosphor coater

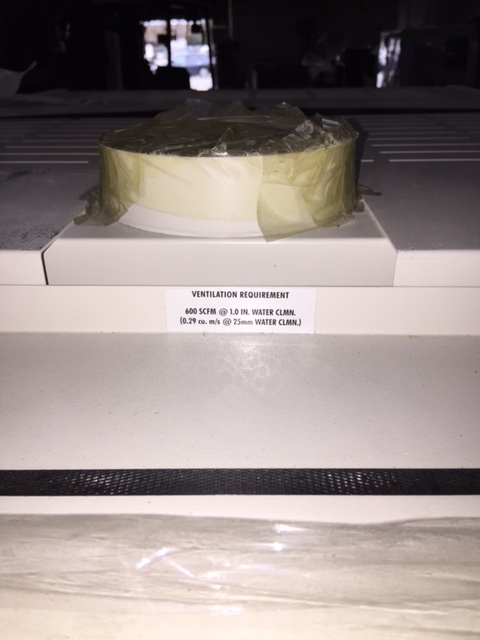

(1) / 99-013574 / Cup, purge, ventilated

(2) / 99-013524 / Pumps, peristaltic, phosphor- 55 cc

(1) / 99-014189 / Circulate pump tubes 55 cc (50 Fits)

(1) / 99-014634 / Differential pressure gauge

(10) 99-013730 / Spray valve particle accumulation improvements

(1) / 99-013518 / Regulator, EP, high res, 0-14 PSI

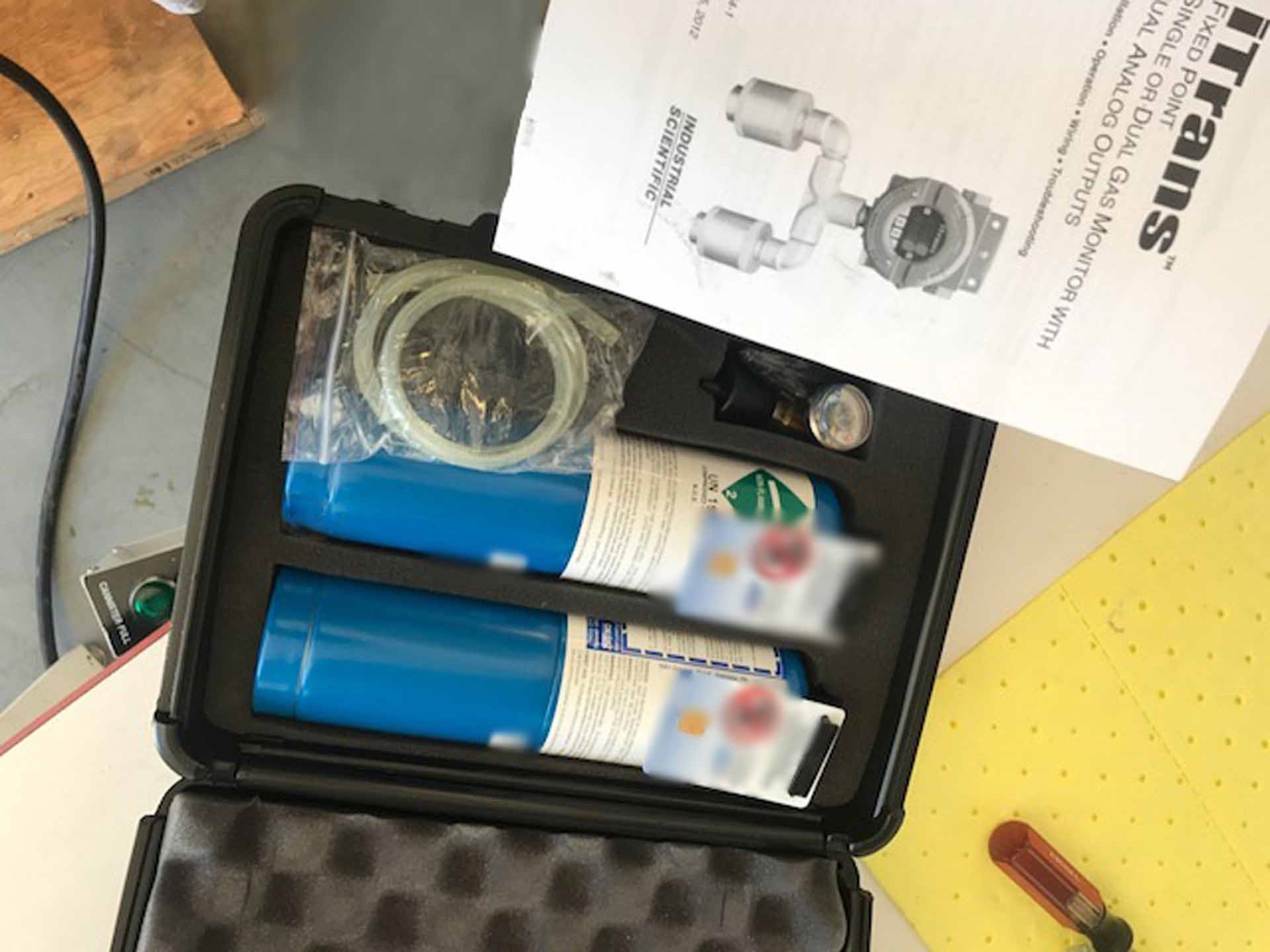

(1) / 99-013305 / OPT, Sensor, VOC, LEL

(1) / 99-013573 / UPGD, Power MGR, 30 A

(2) / 99-014905 / Stirrers, 30/55 cc, phosphor

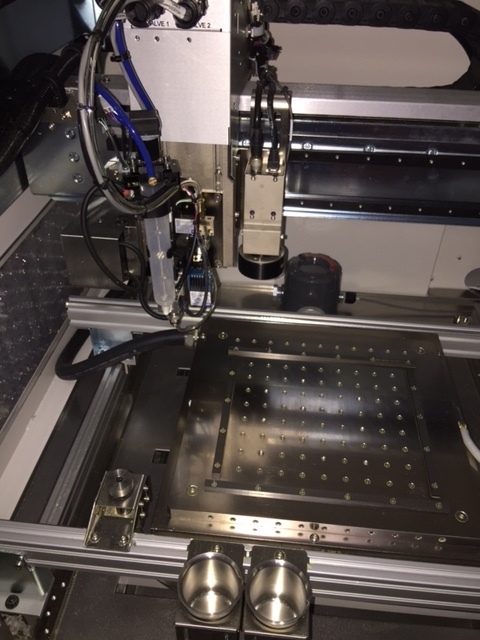

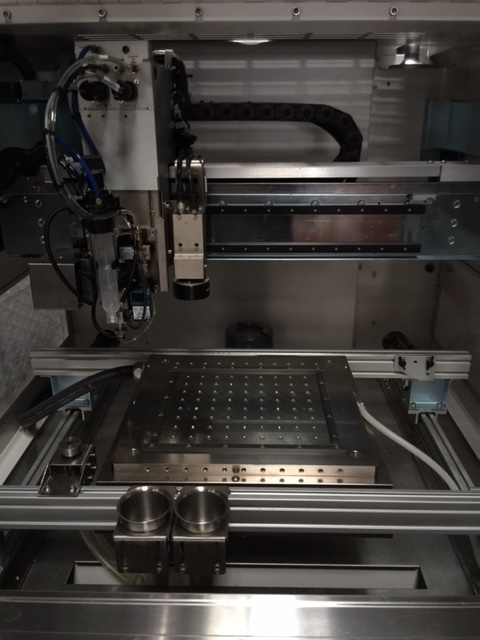

(1) / 99-013522 / Integrated Heated VAC tooling

(1) / 99-014441 / Tooling, 300 mm x 300 tooling - lightning

(1) / 99-013577 / Integrated, phosphor spray valve

(1) / 99-014208 / N2 Air input

(1) / 99-014848 / SL94xE Interlock ring

(1) / 99-014847 / Circulate pump cartridge modification for 55 cc

(2) / 99-014819 / Assy, air cap, 22.5°, 440 SS

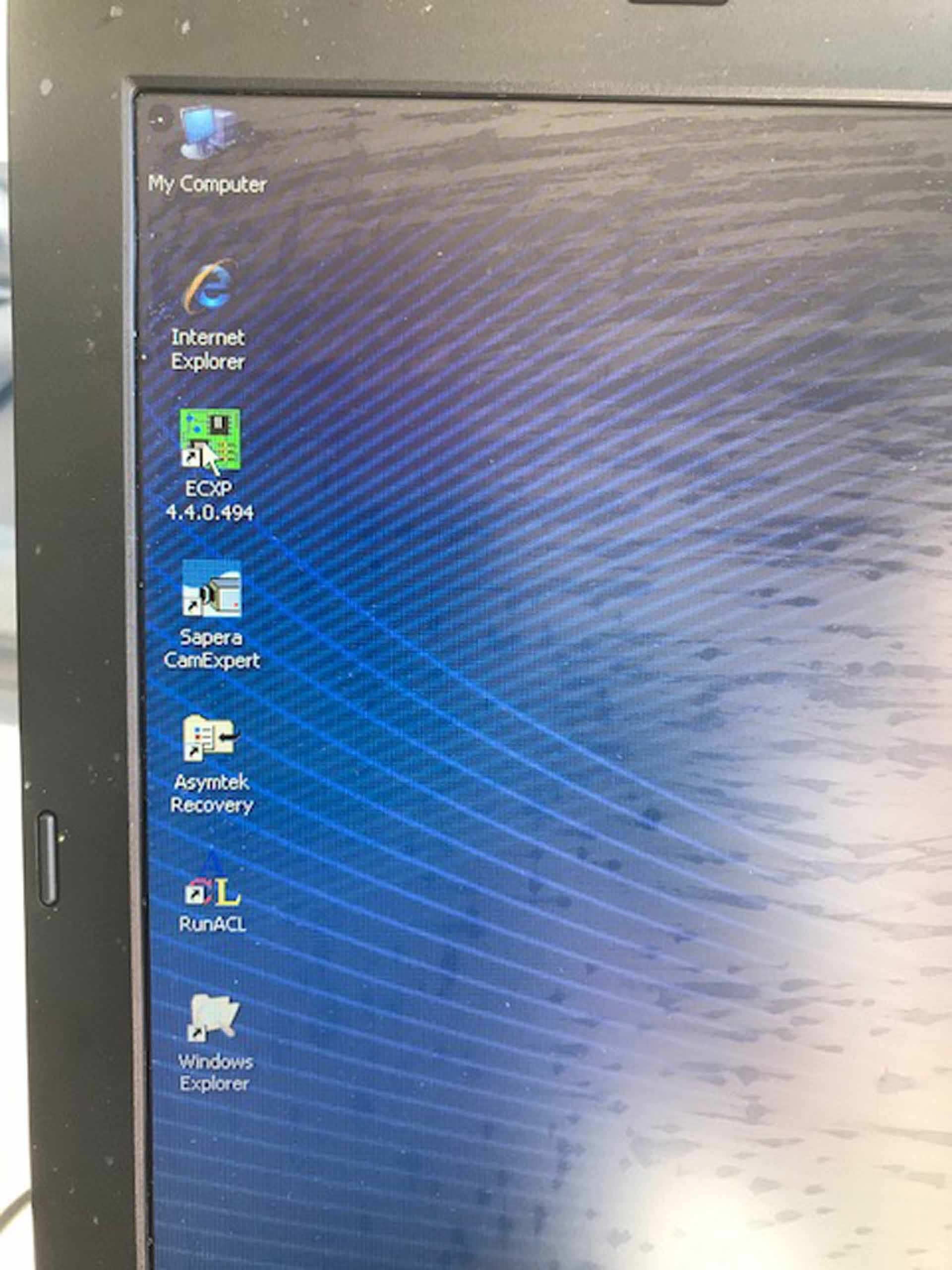

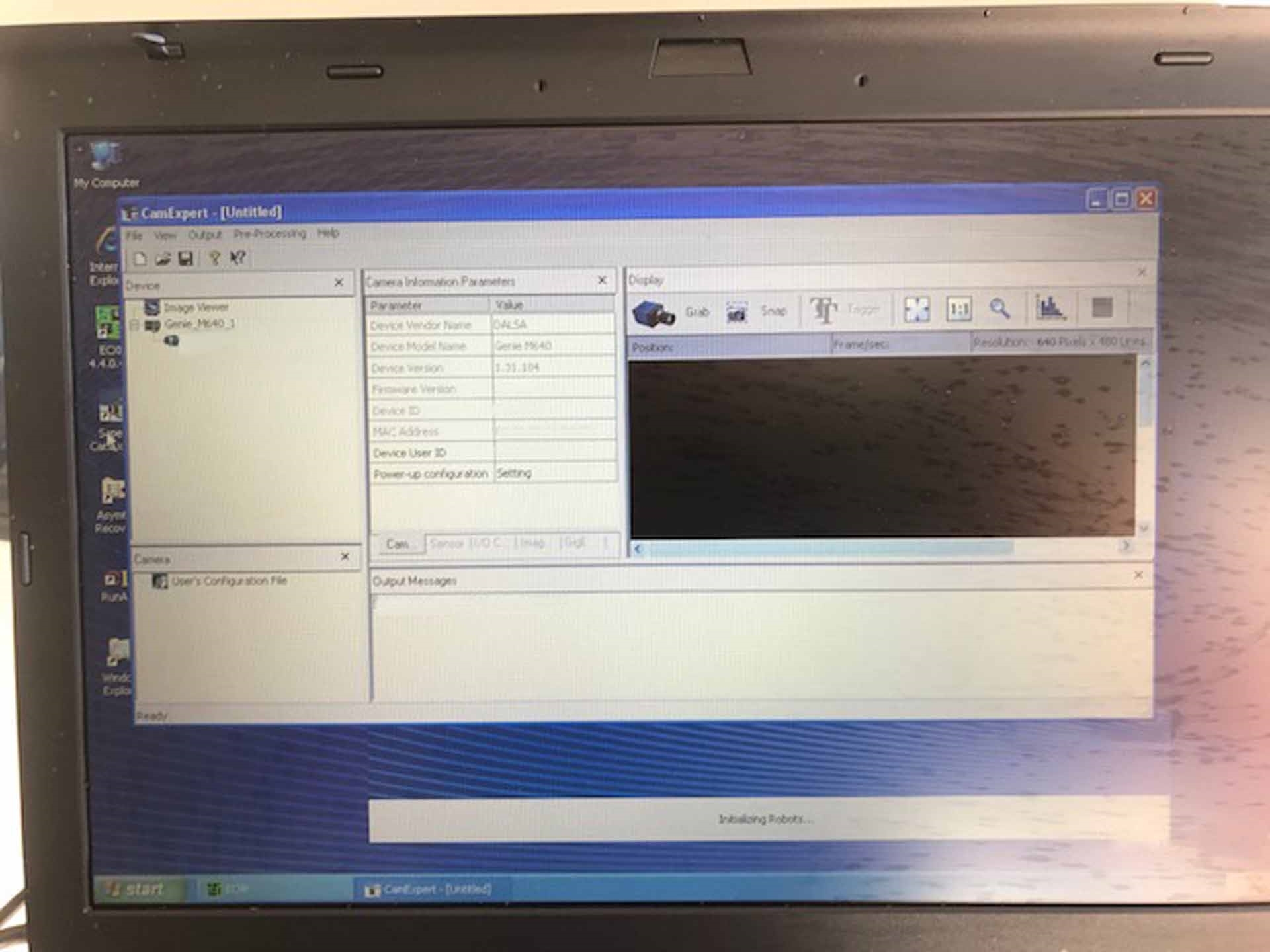

(1) / 7216280 / Vision system with PRS

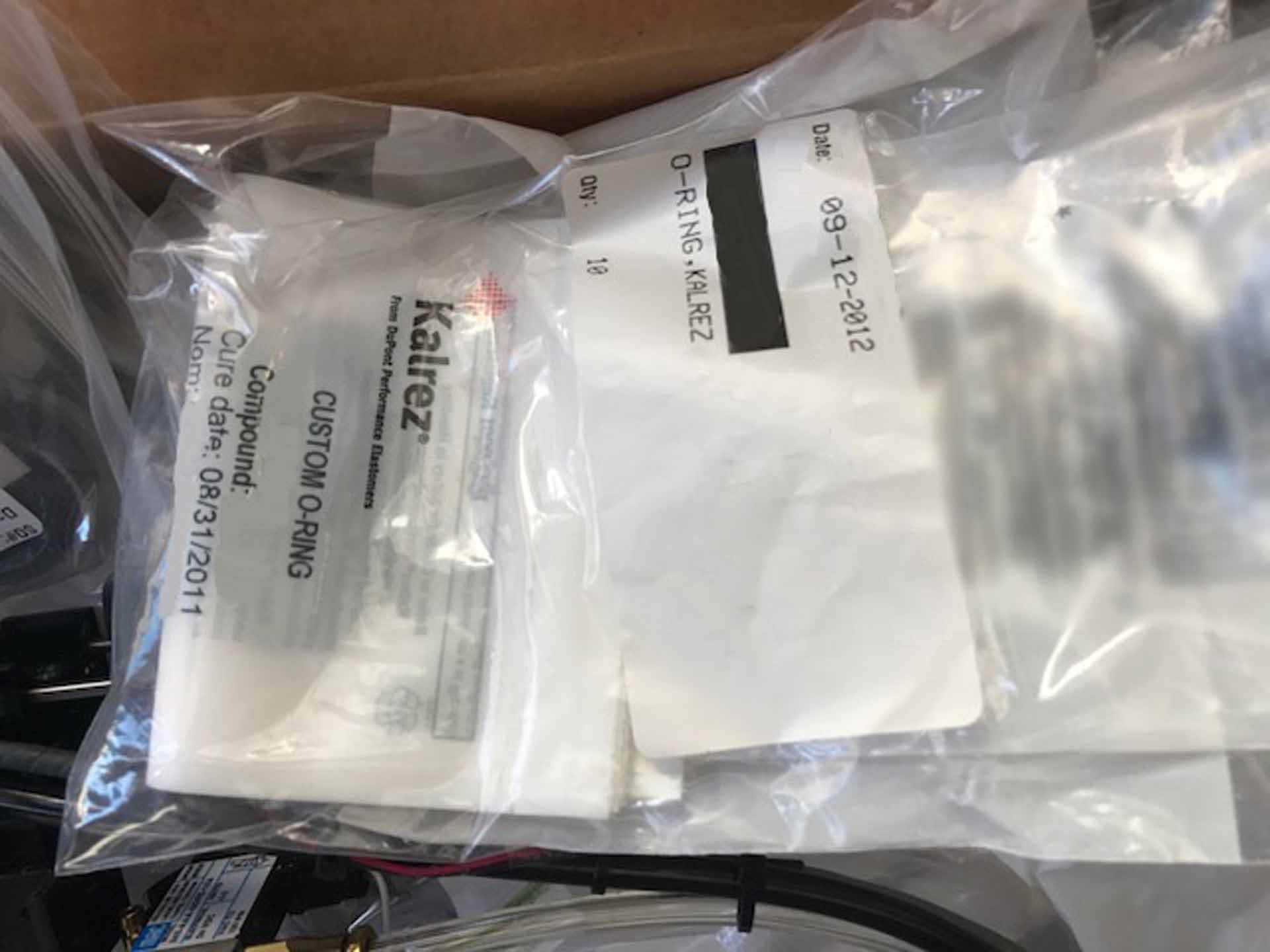

(10) / 940139 / White (Chemraz) O-rings

(10) / 168824 / U-Cup seals

(10) / 719082 / O-Rings, KALREZ, 0.563 x 0.688 x 0.063

(10) / 940090 / Seal lock nut O-rings

(1) / 249942 / Solenoid valve (3-Way , 24 DC ,120 PSI)

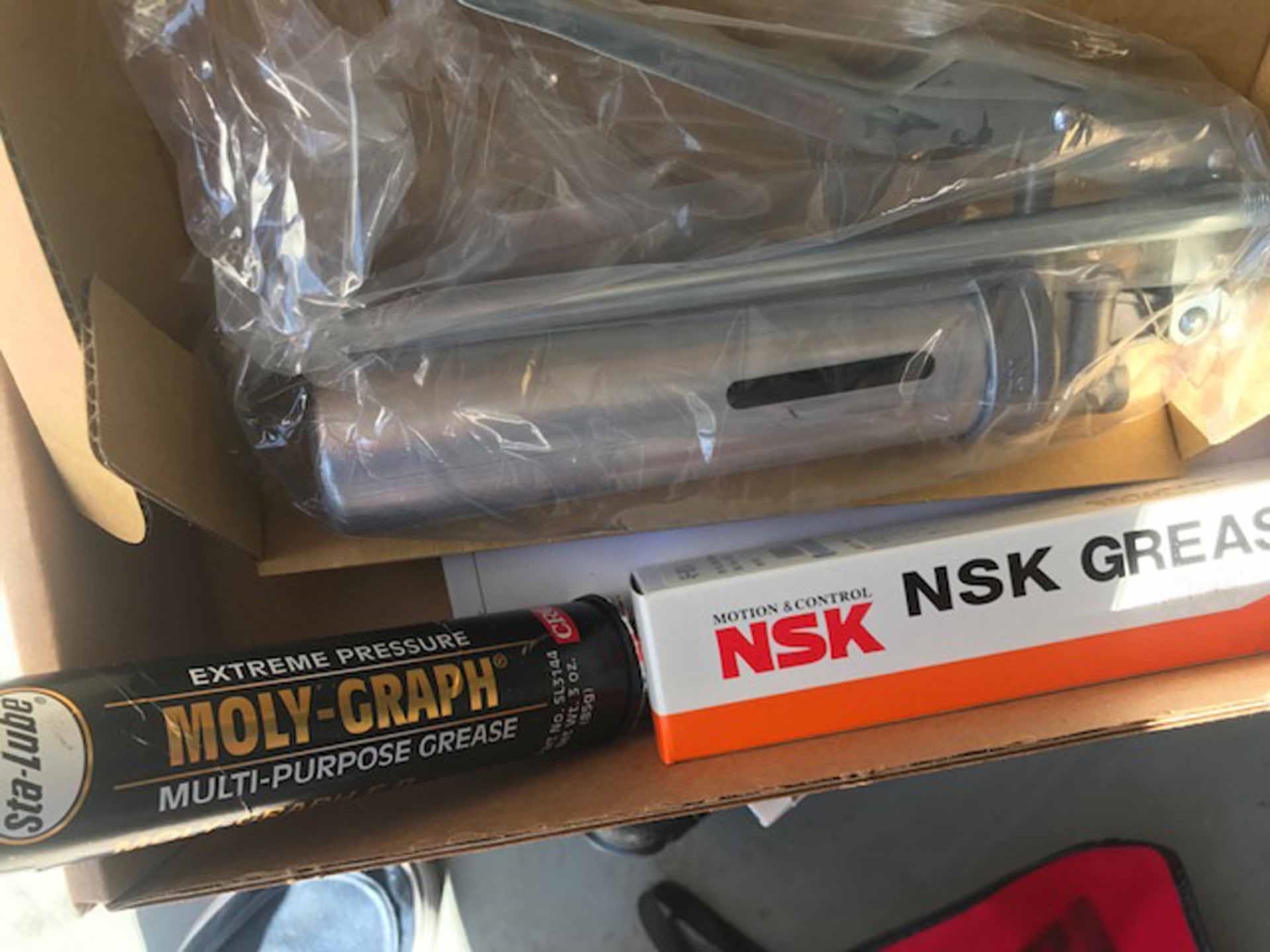

(1) / 7217284 / Micrometer assembly

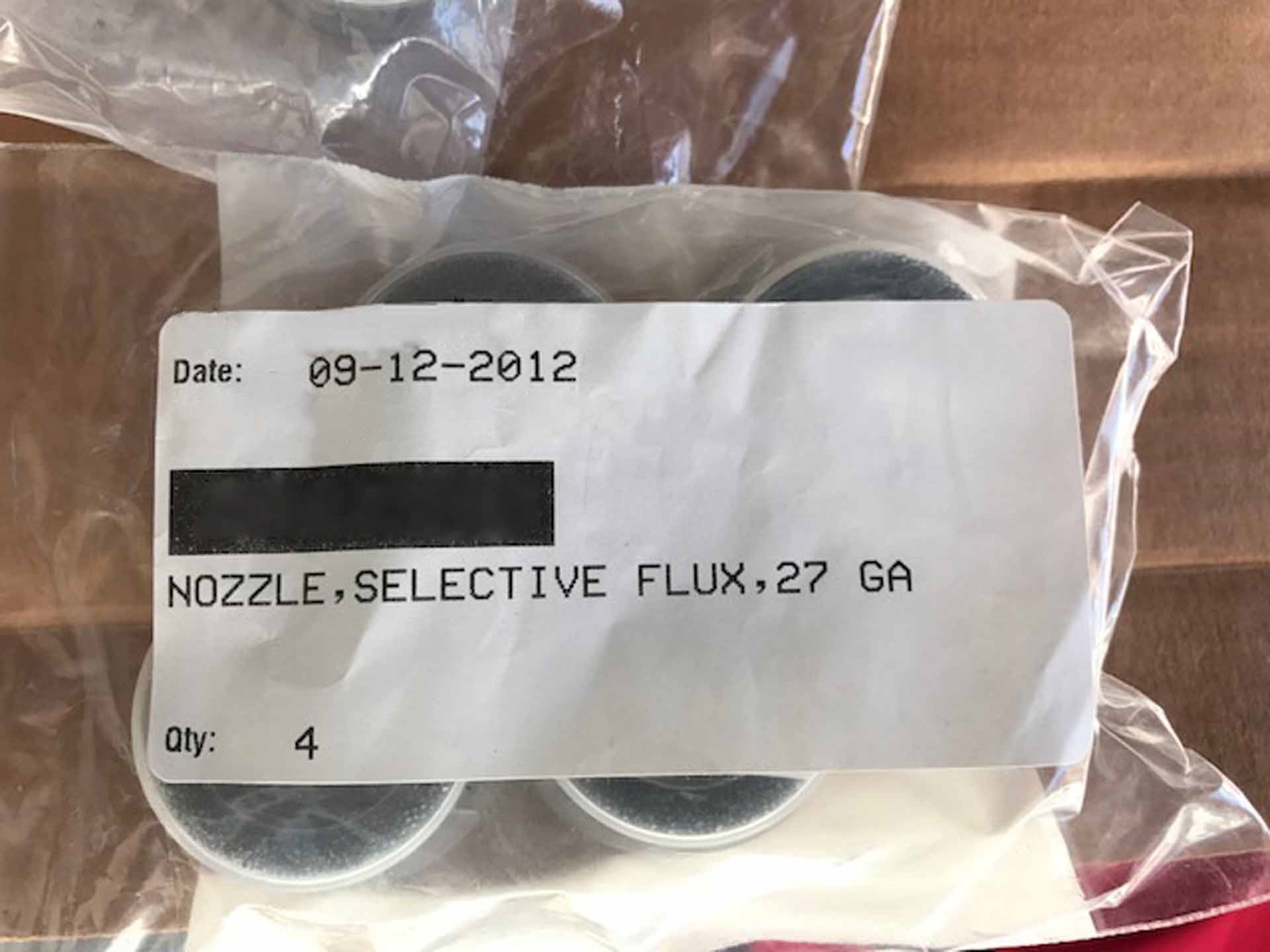

(4) / 391782 / Fluid nozzles, 26 gauge

(2) / 338757 / DJ-2200 Applicator seal kits and consumables

(2) / 7216330 / Assy, air cap, tan 225.5°, TQ

(10) / 332496 / O-Rings, KALREZ, 0.07 ID x 0.04 W

(4) / 391783 / Fluid nozzles, 27 gauge

(10) / 955055 / Seals, FLUOROLOYG, 0.313 x 0.125

2012 vintage.

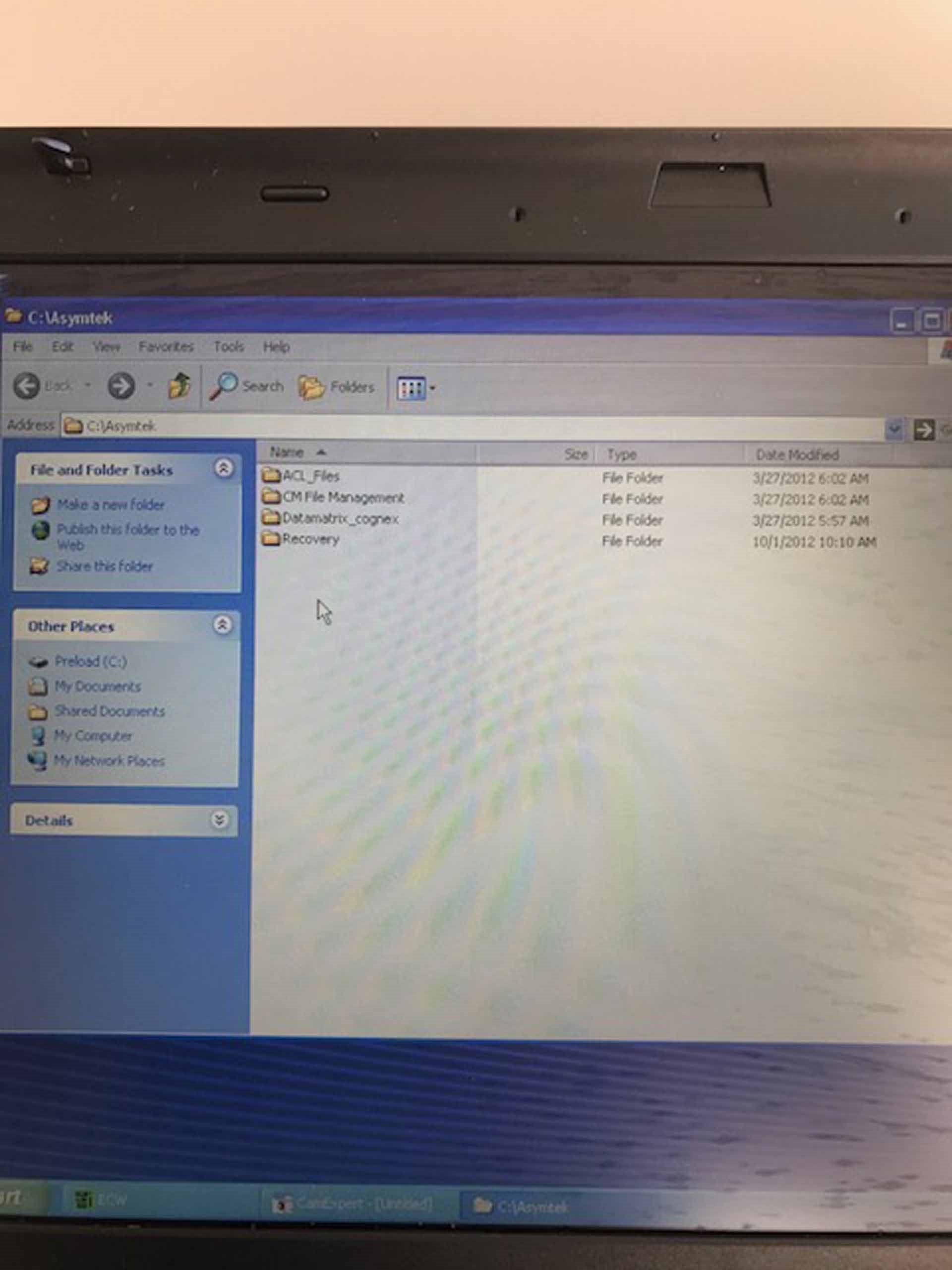

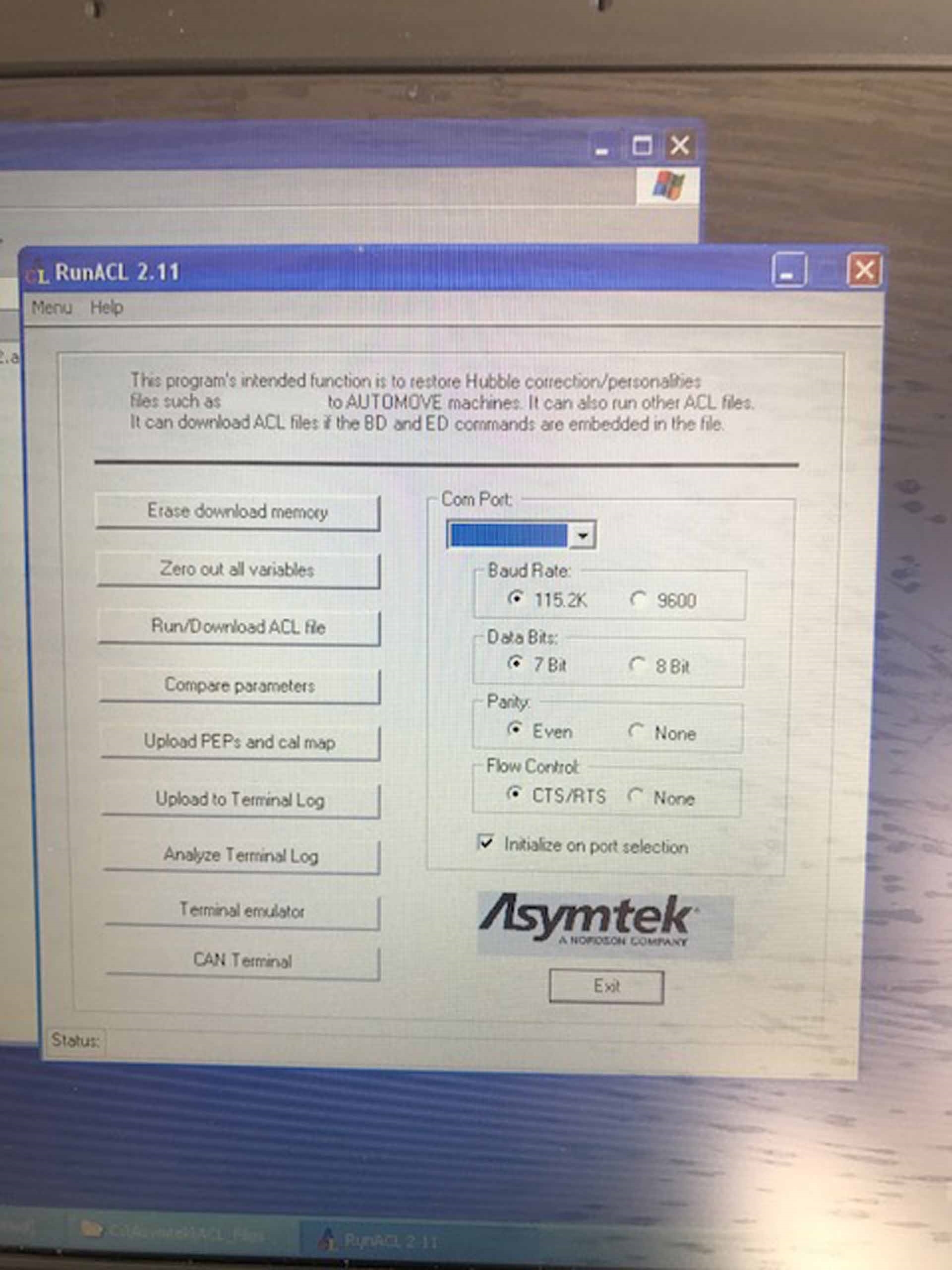

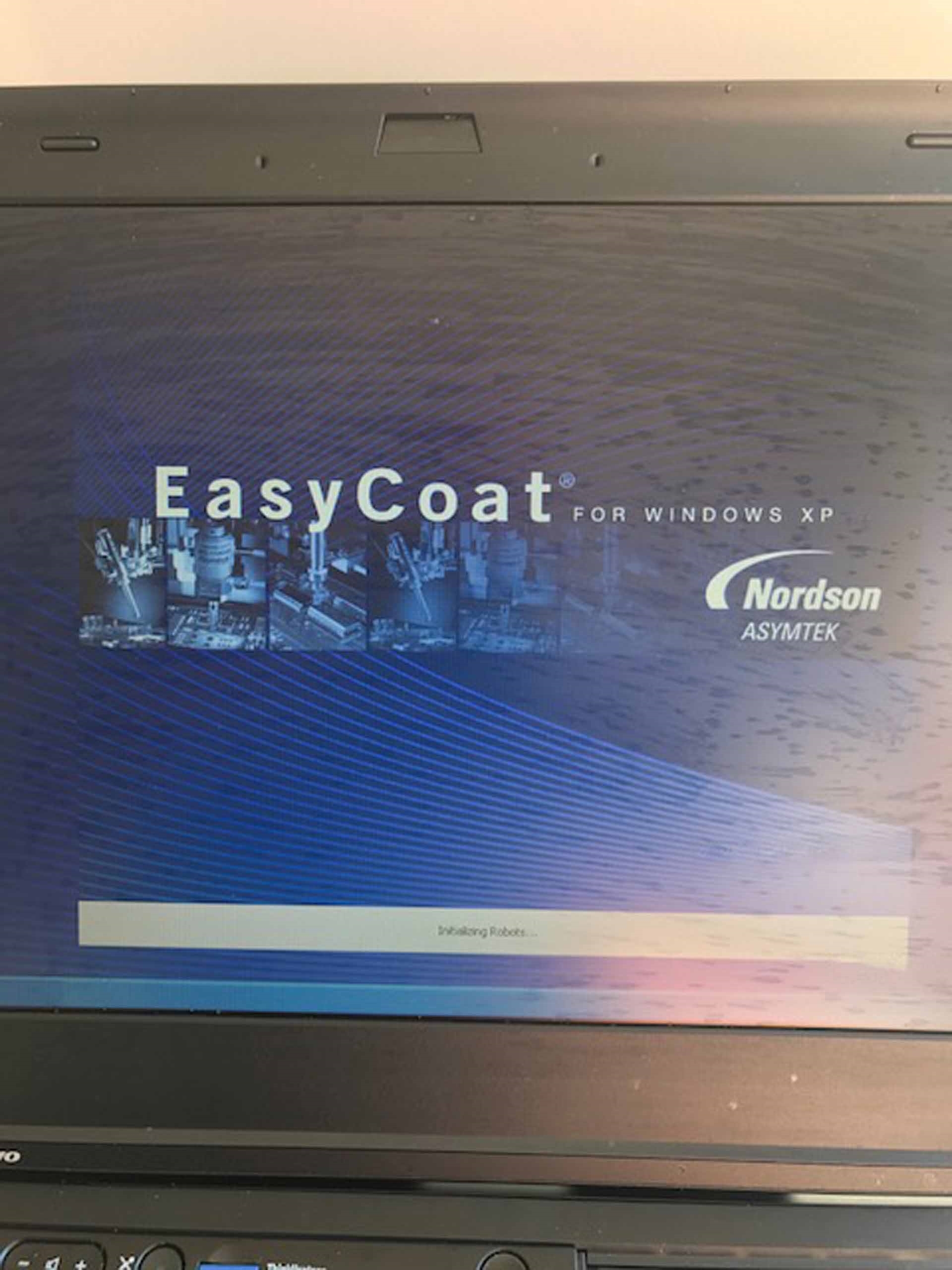

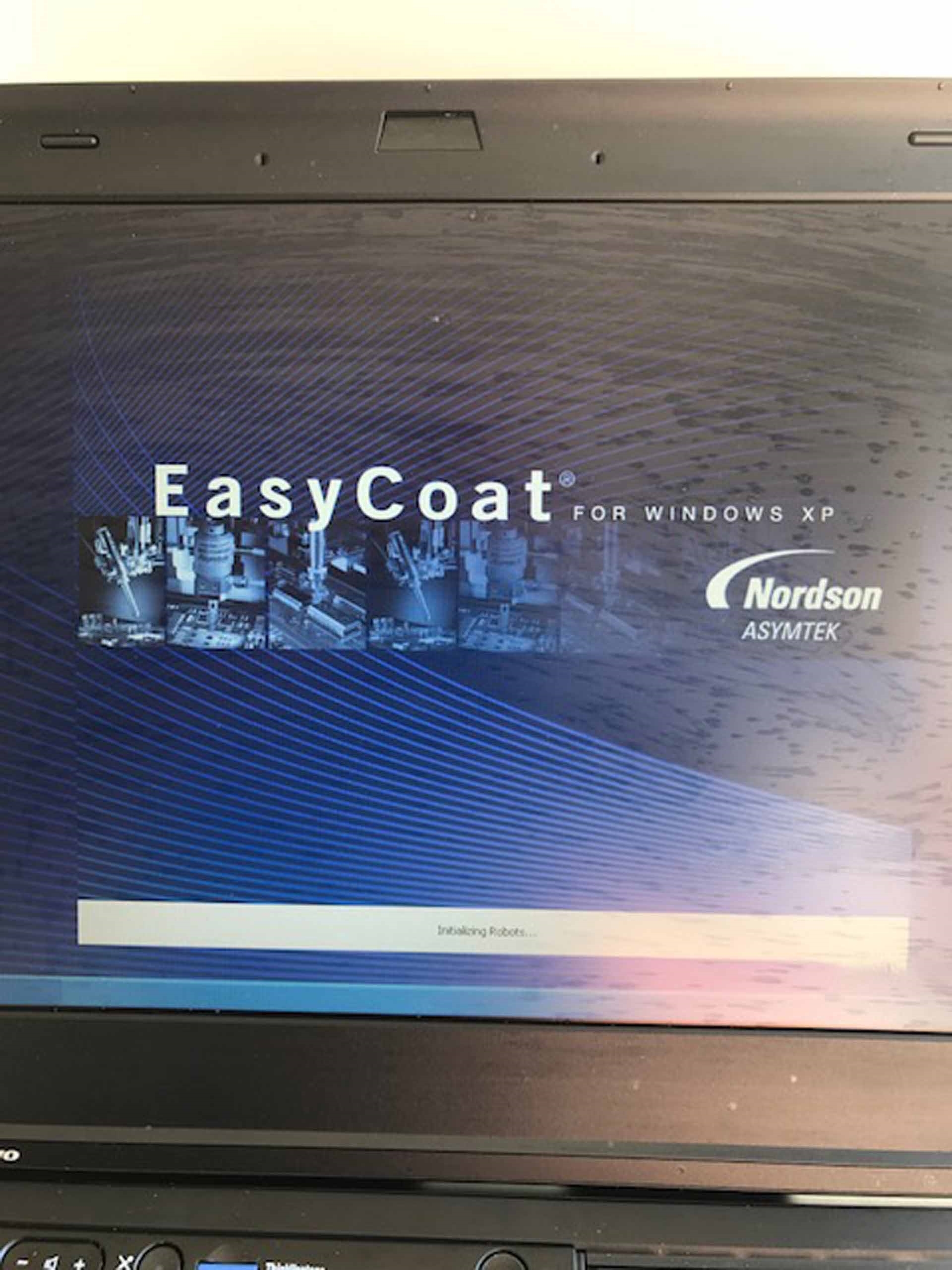

NORDSON / ASYMTEK S-820 is a PC board assembly and manufacturing equipment designed for the automated assembly and inspection of printed circuit boards (PCBs). This system is equipped with advanced motion and vision technologies and features a flexible and easy to use platform. It is designed to provide high accuracy, speed, repeatability, and reliability. NORDSON S-820 is equipped with an advanced custom vision unit which is used to identify and inspect components for accuracy. The vision machine is capable of detecting color, shape, size, position, and orientation of components, as well as verifying part numbers on component labels. It also has an adjustable Zoom-in imaging capability to provide high-magnification visuals allowing for precise vision inspection. Additionally, the vision tool can be used to help detect defects such as a missing component, component misalignment, burrs, chips, and scratches in the contact area. ASYMTEK S 820 is equipped with advanced motion control technology which allows for accurate placement and assembly of components and improves component insertion accuracy. The asset is also equipped with an integrated robotic arm for high-precision material handling which improves material accuracy and cycle time. The robotic arm is designed to be intuitive and allows multiple components to be arrayed in one simultaneous operation. In addition, ASYMTEK S-820 model is fully integrated with a quality tracking equipment, which streamlines the material management process. This system helps to ensure the highest quality components are used in the assembly process and helps to identify and eliminate defective parts and materials. Additionally, the quality tracking unit tracks component inspection data, allowing for more accurate component traceability and overall traceability throughout the entire assembly process. S 820 is also designed to be cost-effective and efficient. It is equipped with an efficient and powerful PC-based Windows operating machine, eliminating the need for complex hardware or software. Additionally, the tool features a user-friendly interface which allows for easy programming and setup. NORDSON S 820 is designed for minimal maintenance and is certified to ISO 9001 and ISO 14000 standards, providing the highest quality process control and reducing downtime. In summary, S-820 is a cutting-edge PC board assembly and manufacturing asset, designed for the automated assembly and inspection of printed circuit boards. It is equipped with advanced motion and vision technology and an integrated robotic arm for high-precision material handling. Furthermore, it features a powerful PC-based Windows operating model, intuitive user interface, integrated quality tracking equipment, and is certified to ISO 9001 and ISO 14000 standards. NORDSON / ASYMTEK S 820 system offers an effective, efficient, easy to use, and cost-effective solution for PCB assembly and manufacturing.

There are no reviews yet