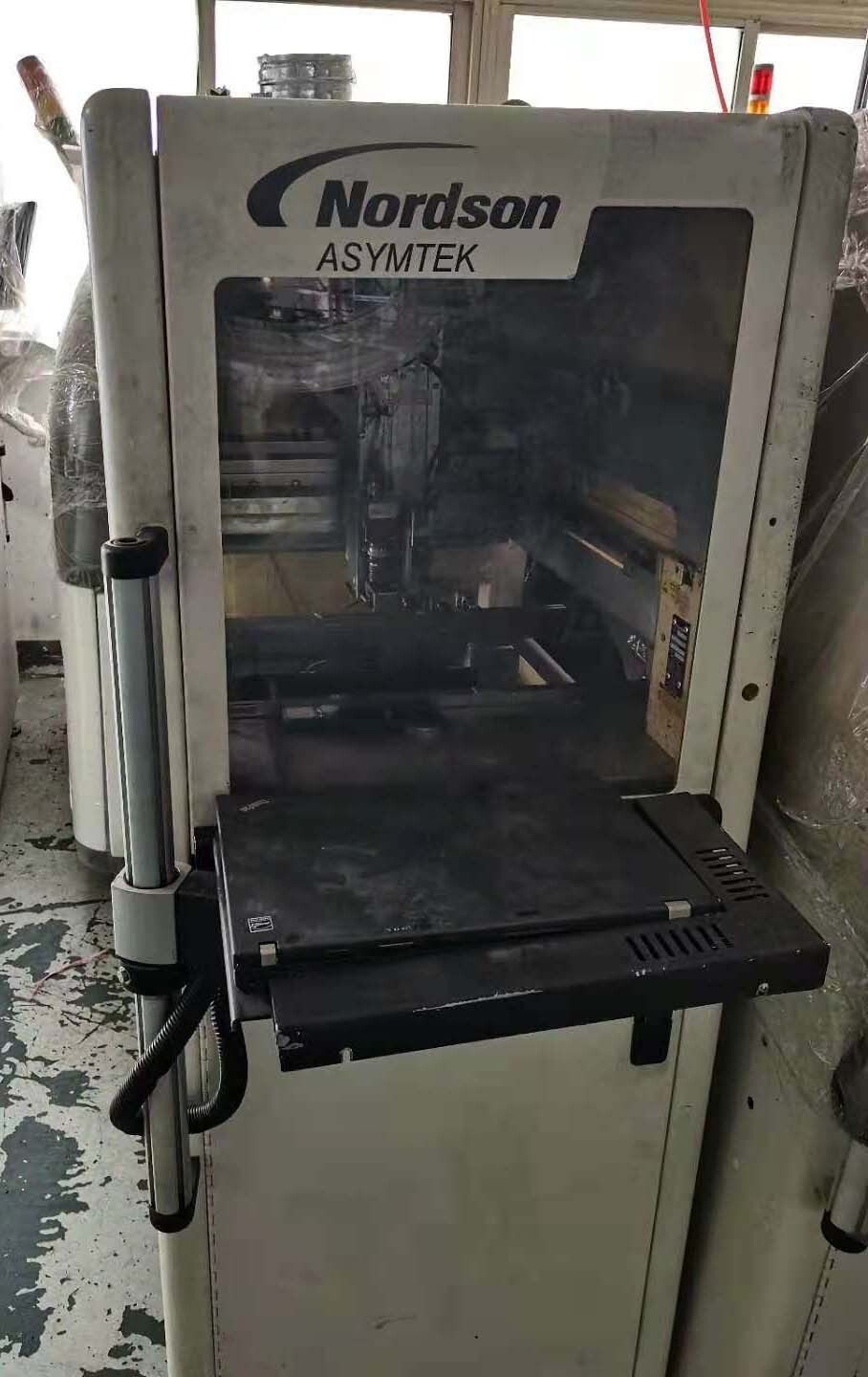

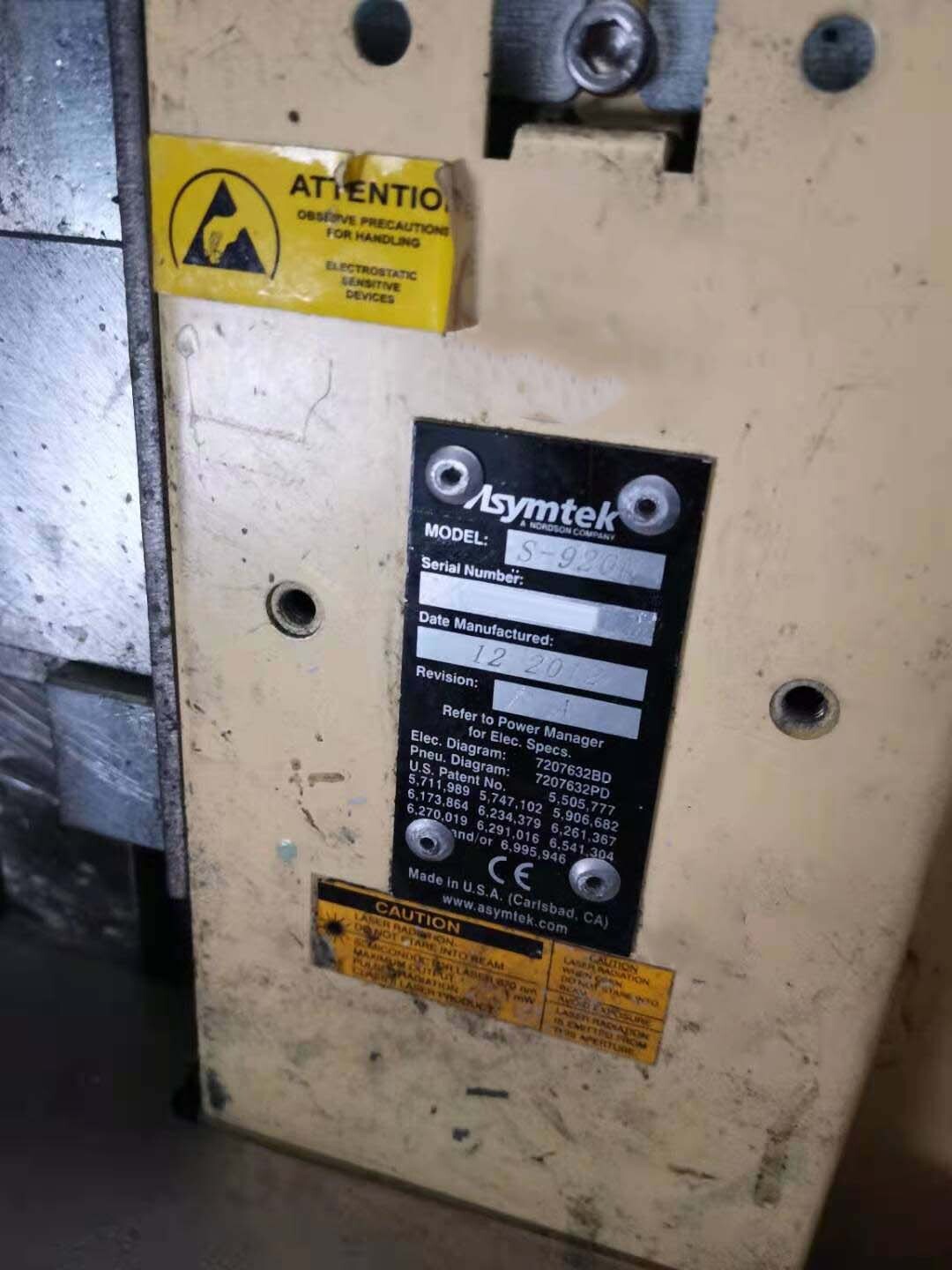

Used NORDSON / ASYMTEK S-920N #293606864 for sale

URL successfully copied!

Tap to zoom

NORDSON / ASYMTEK S-920N is a fully automated PC board assembly and manufacturing equipment designed for precision, high-volume production. It is equipped with an advanced vision system for advanced part detection and pick-and-place accuracy. The unit includes both standard and optional features to accommodate diverse application requirements. NORDSON S-920N features a dual-lane belt conveyor machine for accurate and efficient component placement. It offers a wide range of component feeders for both through-hole and surface-mount technology, including general feeders, high-speed servo-controlled feeders, and precision-feeders. An integrated component-checker function inspects component accuracy, ensuring only correctly placed components are used. ASYMTEK S-920N comes with an AsymCad CAD interface, simplifying the setup of component placement, enabling faster program creation. The tool is compatible with an array of dispenser modules, providing the user with a wide range of fluid dispensing and jetting capabilities. It is also supported by a comprehensive library of stencils, as well as a solder jetting subsystem that allows fine-pitch soldering. The asset is equipped with four-axis robotic arm, enabling mount accuracy. Its advanced vision model further enhances robotic accuracy by providing quick detection, leading to high placement accuracy. The equipment includes intuitive user features, such as real-time part pick-up feedback, jog control, and auto-focus camera control. S-920N also features NORDSON thermal cycling system, which provides full-sonic soldering powered by a closed-loop temperature control unit, optimizing temperature accuracy and repeatability. The machine is equipped with a high-power flow heating tool, offering temperature profiles to meet the specific needs of a process. NORDSON / ASYMTEK S-920N is a highly reliable and accurate automated PC board assembly and manufacturing asset. Its intuitive features and advanced vision model assure precision performance and repeatability. The equipment is also highly compatible, offering flexibility and customization for unique production challenges.

There are no reviews yet