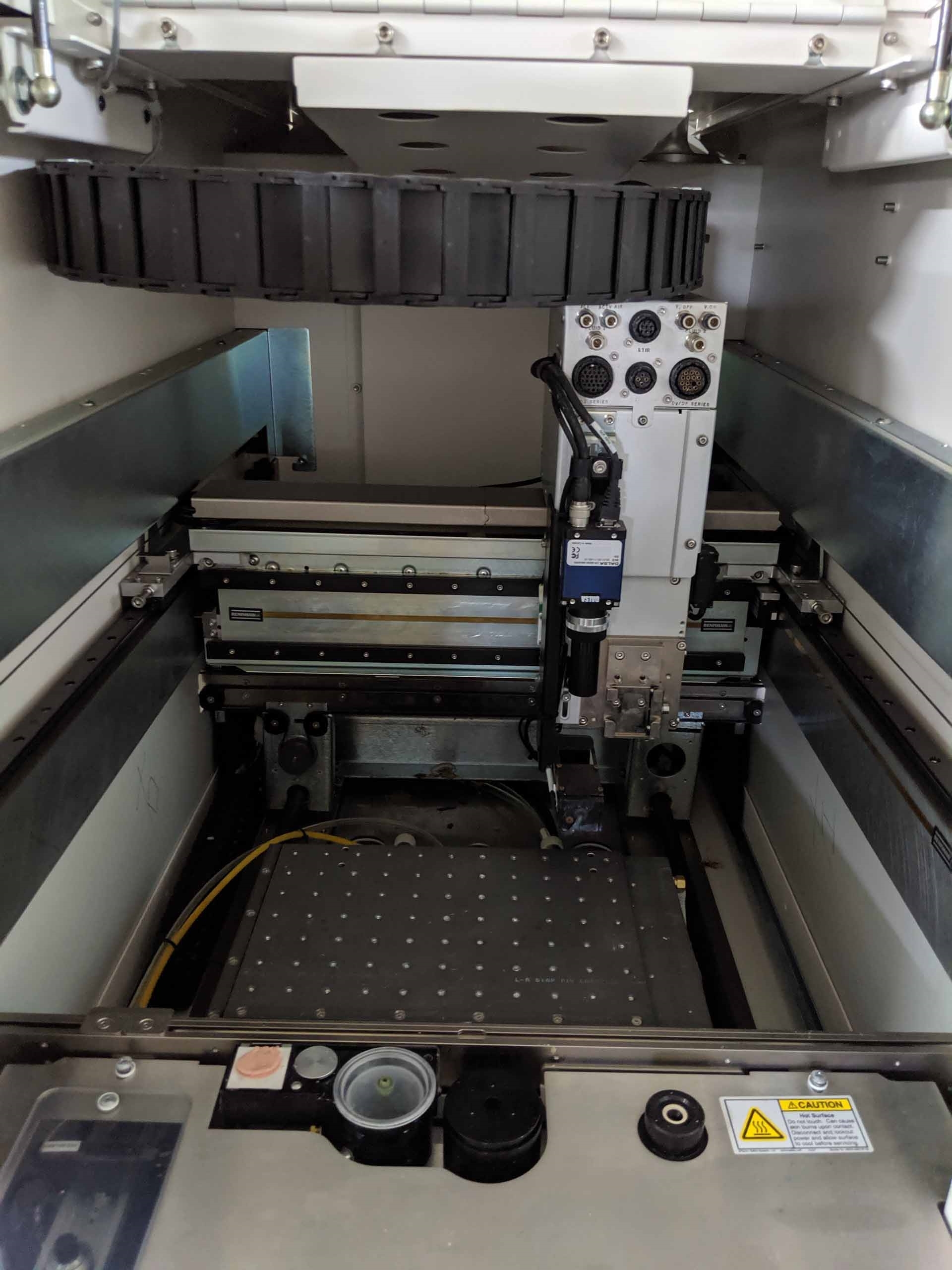

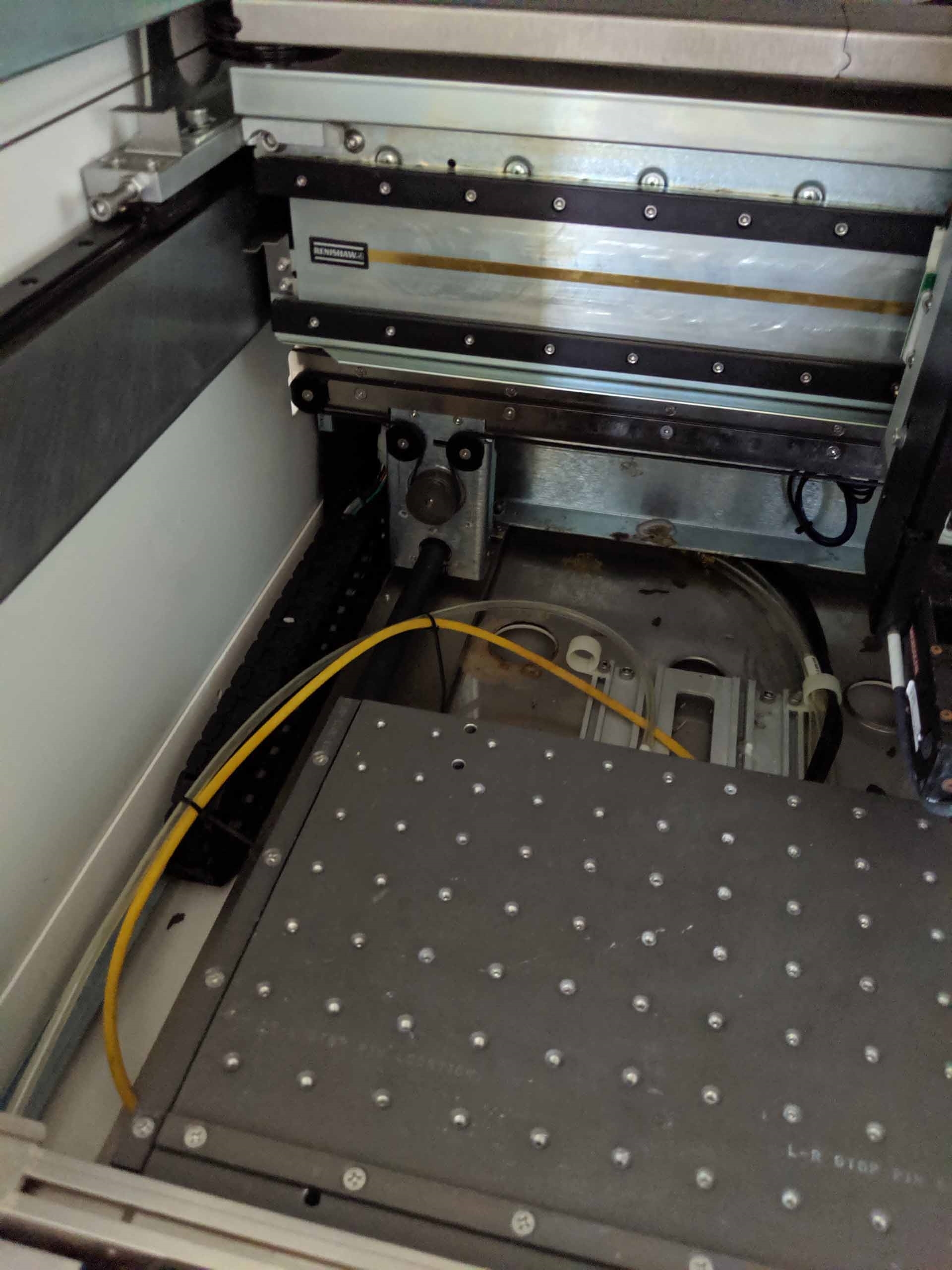

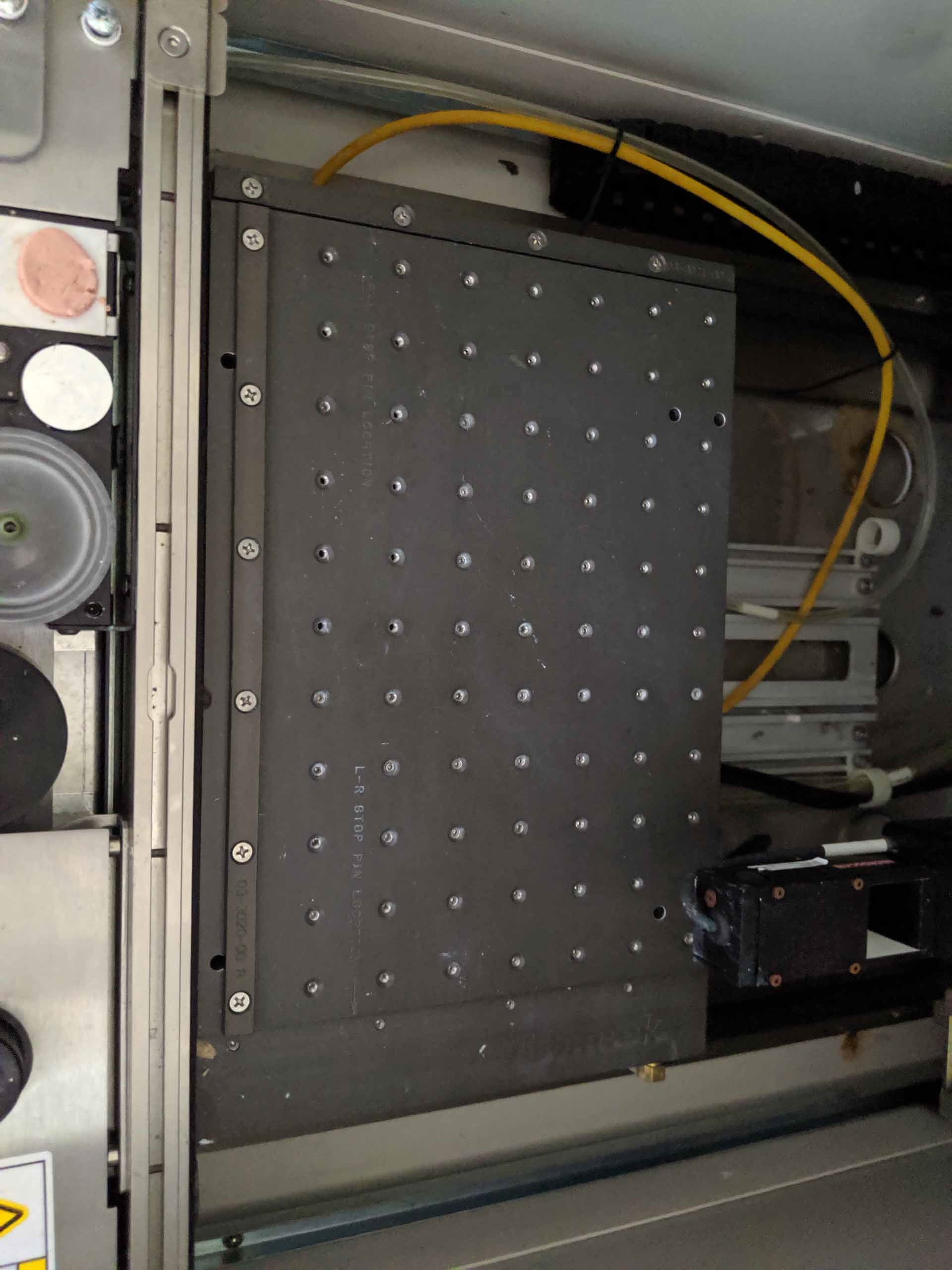

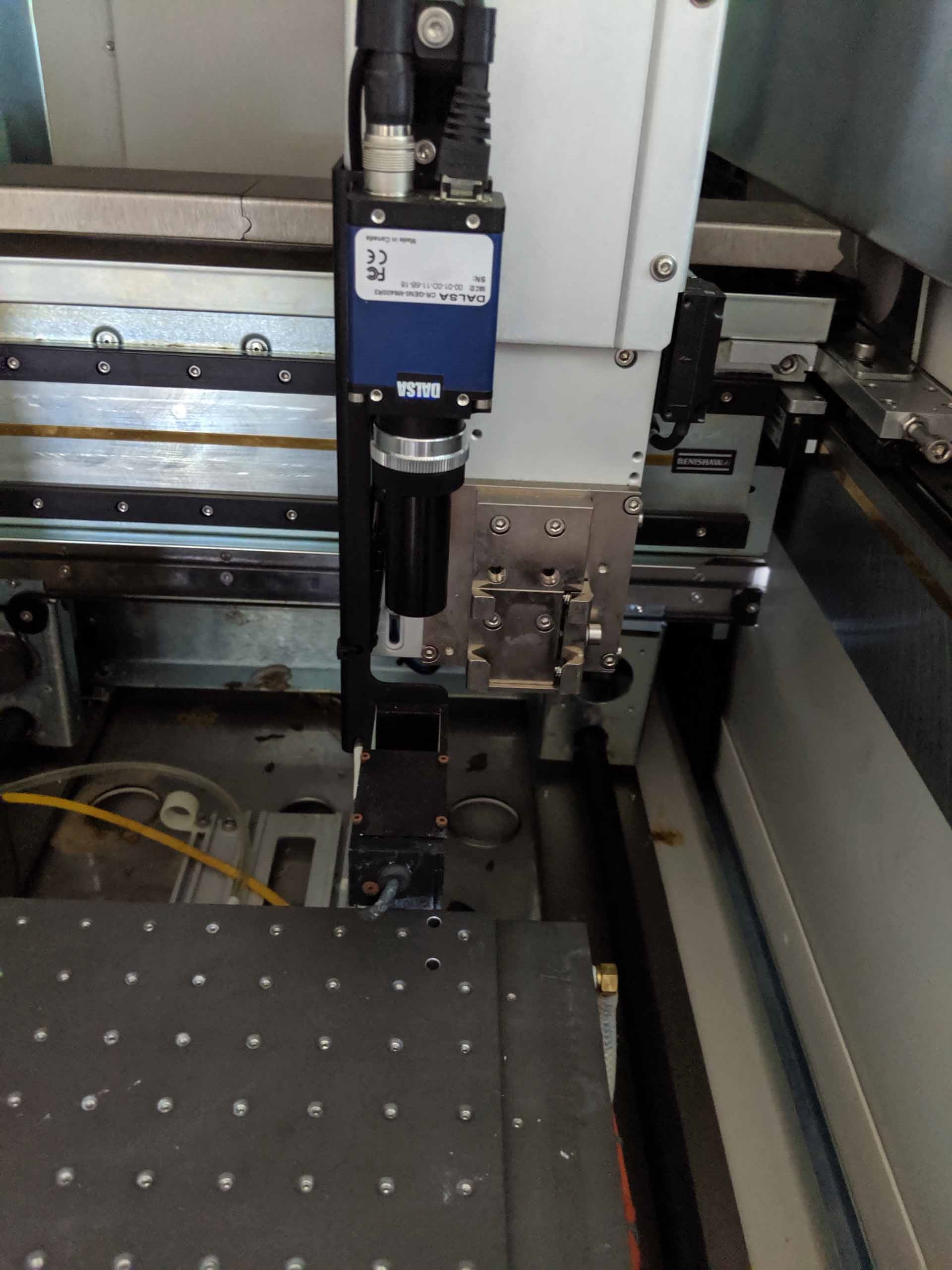

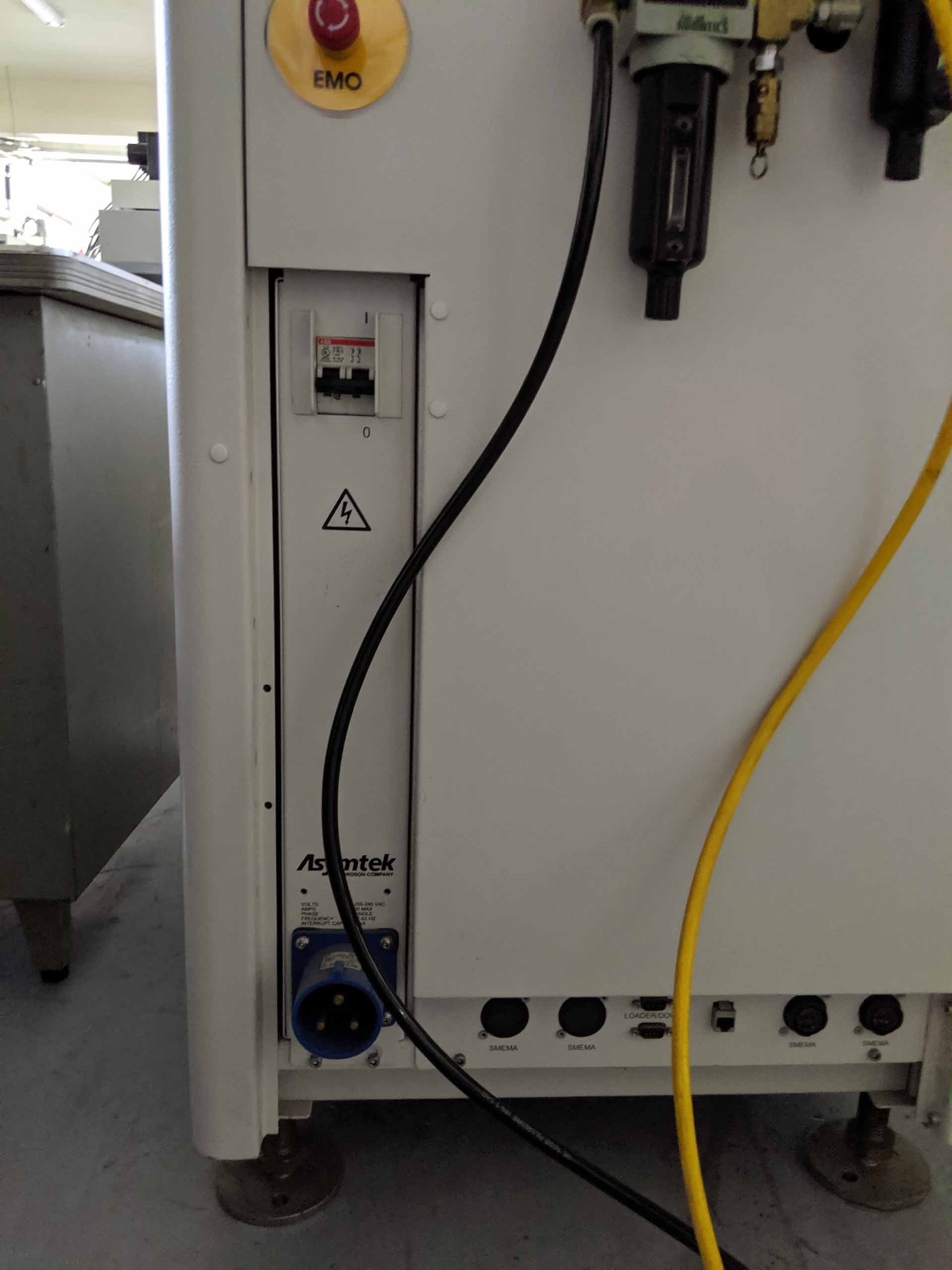

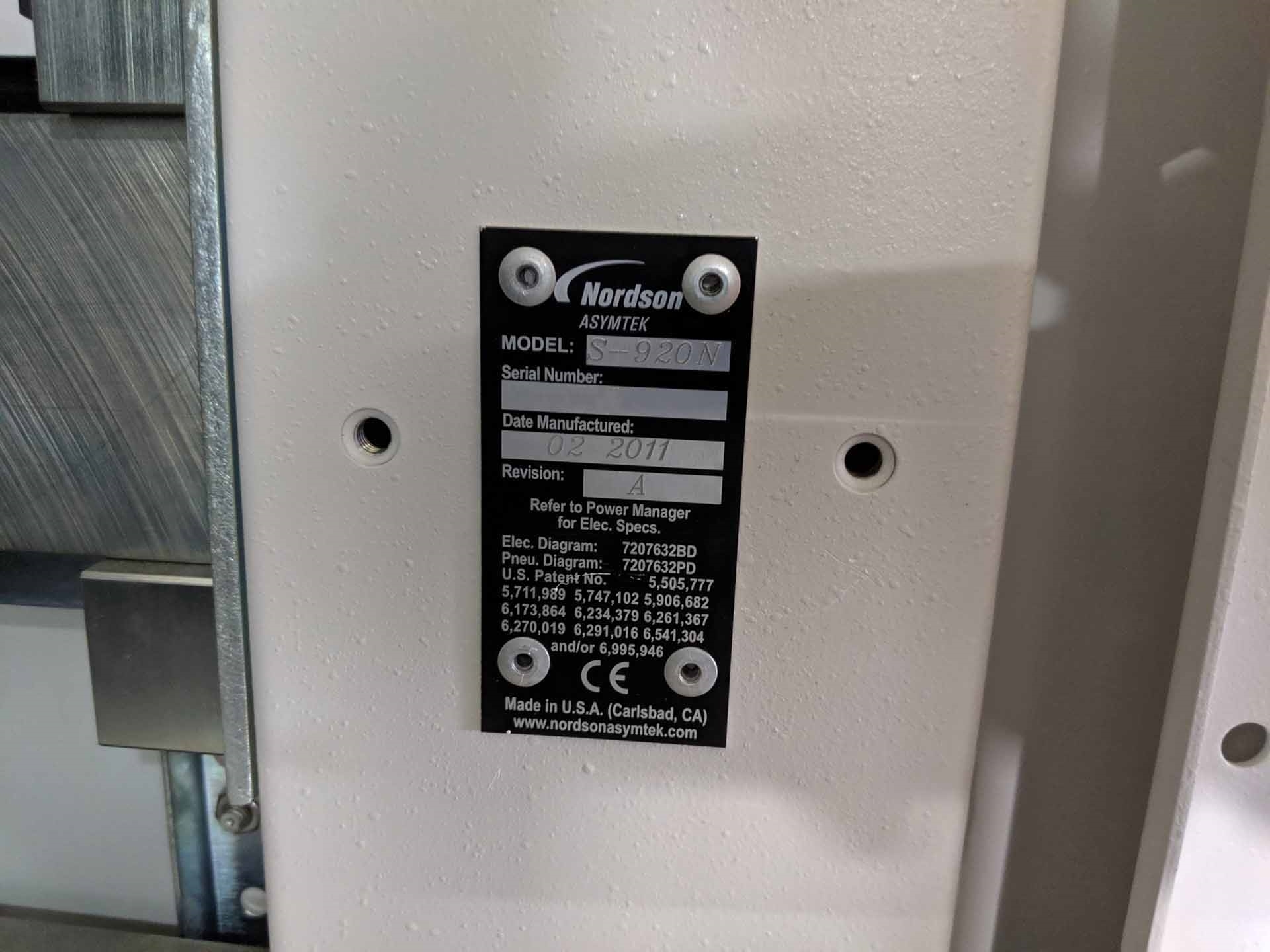

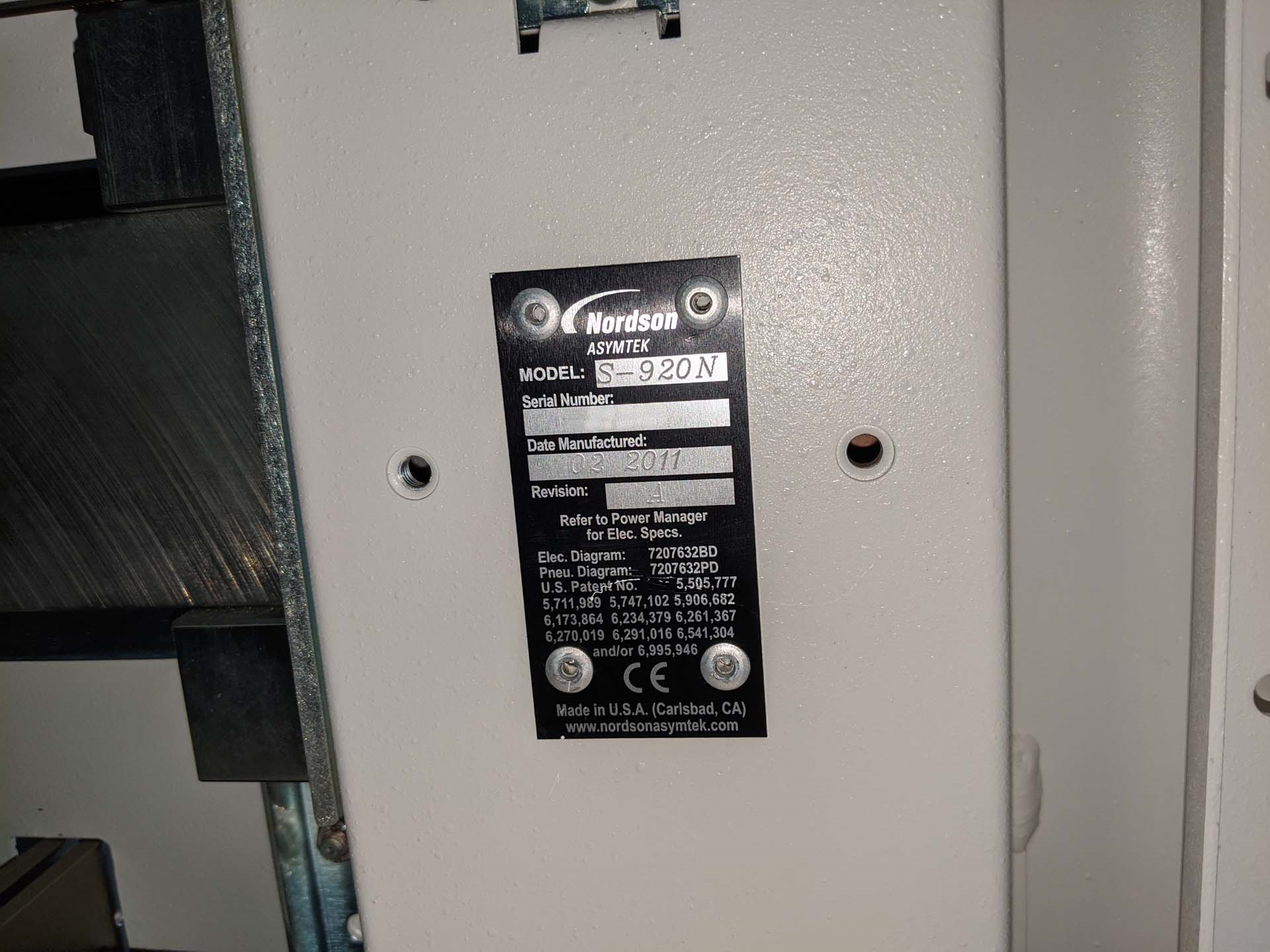

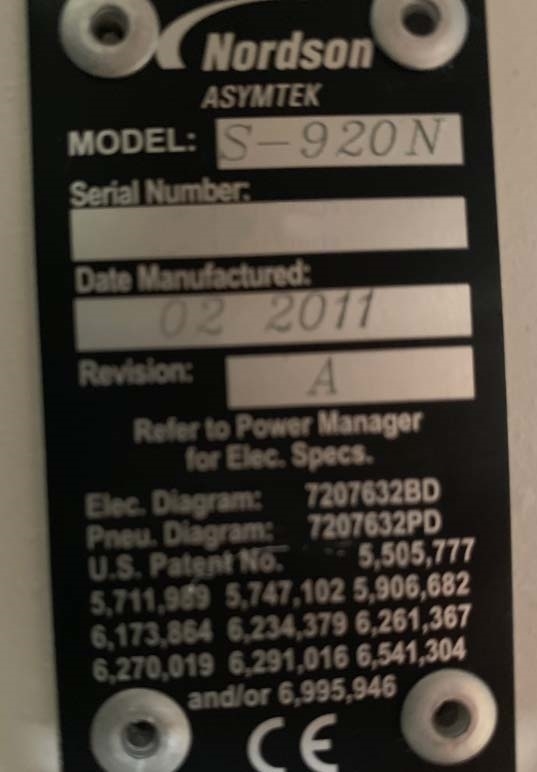

Used NORDSON / ASYMTEK S-920N #9247018 for sale

URL successfully copied!

Tap to zoom

ID: 9247018

Vintage: 2011

Automated fluid dispenser

Single lane

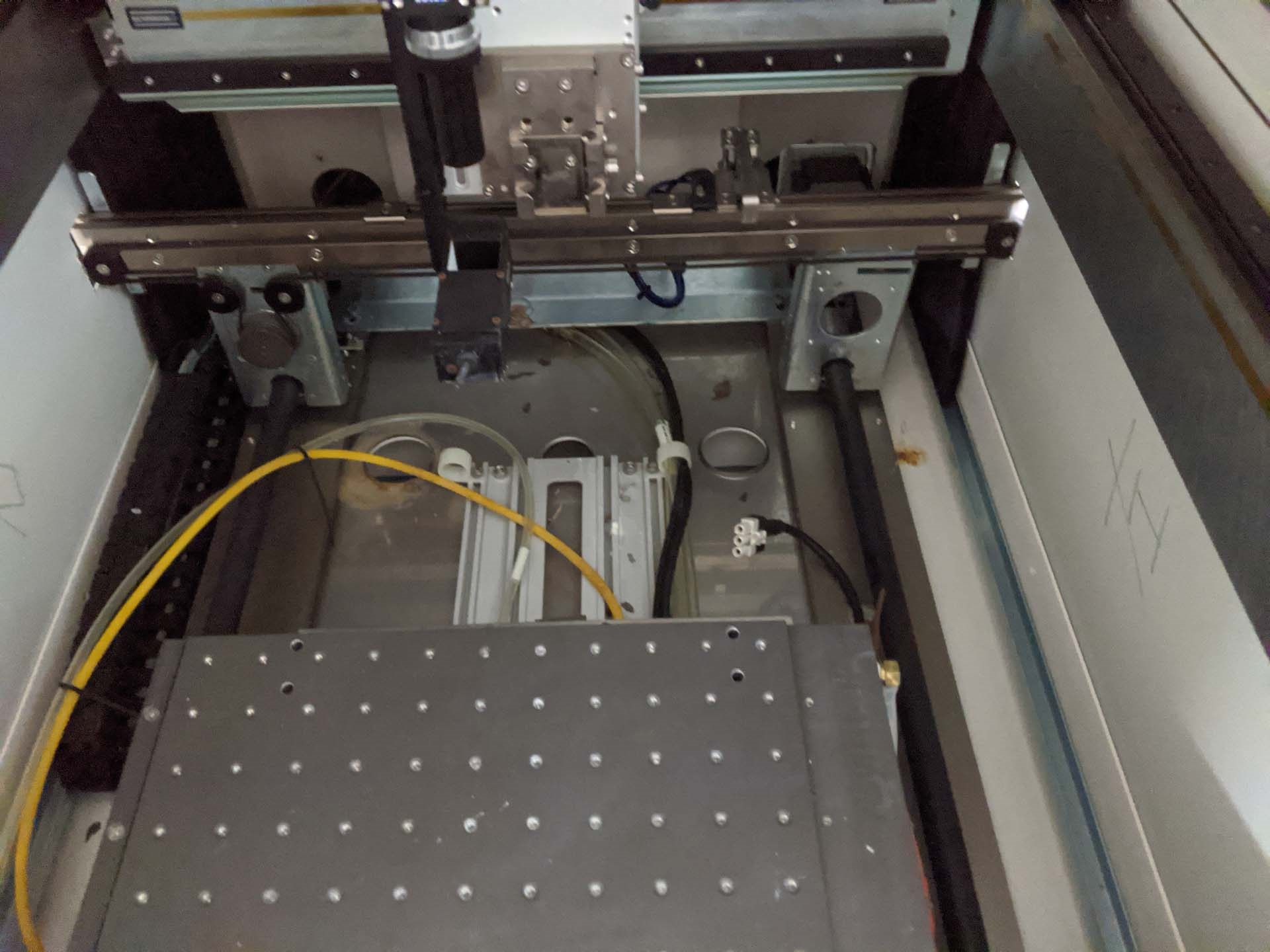

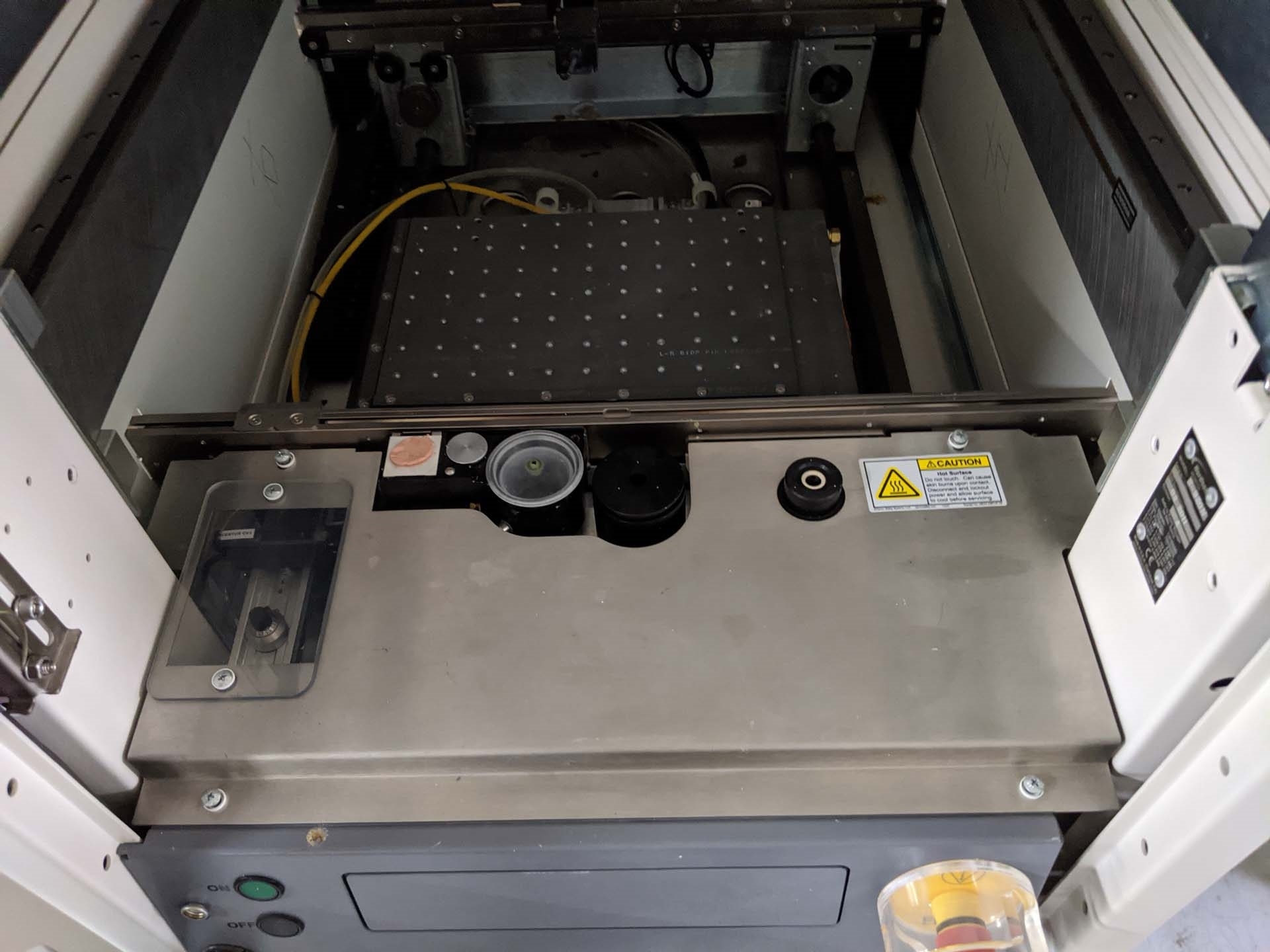

DJ-9500 Dispense jet

Loop processing

Flexible number of heating zones

Optional Controlled Process Heat (CPH)

Digital vision system

Tactile height sensor

Calibrated Process Jetting (CPJ)

Light beacon with audible alarm

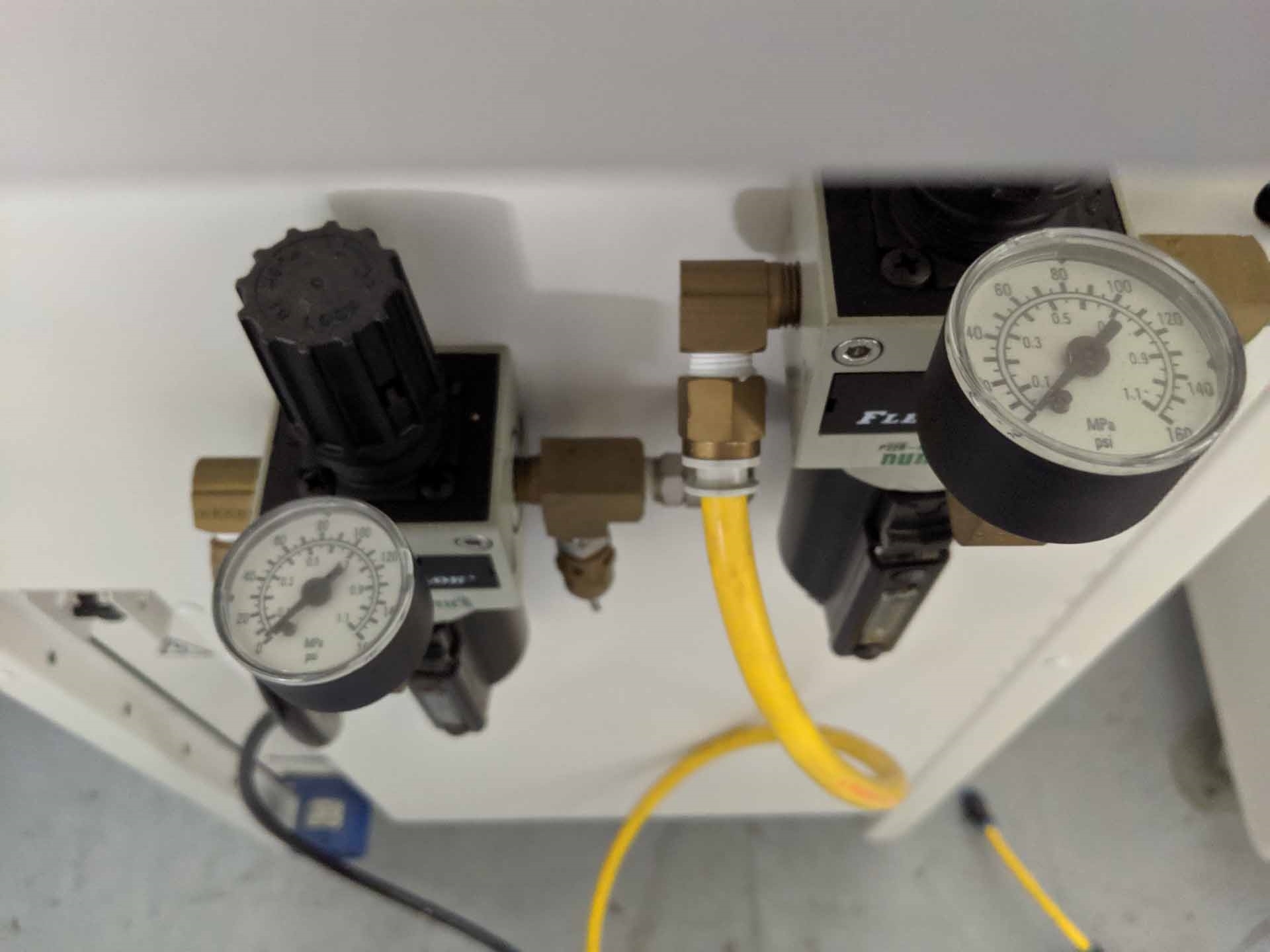

Low pressure sensor

Programmable fluid and valve pressure

Tactile height sensor

Ventilation exhaust system

2011 vintage.

The NORDONNORDSON / ASYMTEK S-920N is a component placement and manufacturing equipment designed for PC board assembly and manufacturing operations. This system is designed to quickly and accurately place and attach electronic components onto a printed circuit board (PCB). NORDSON S-920N utilizes two applicators to give the operator precise control and accurate placement of components while being easy to maintain. The unit primarily consists of two component pick-and-place head components which contain nozzles that rupture large, precut sprues that are associated with the specific part. The high-speed pick-and-place heads include laser vision guidance and backstand vision sensors to ensure accurate placement. The laser vision guidance machine works in tandem with the software-driven nozzle head positioning to ensure precise component placement. ASYMTEK S-920N utilizes liquid flux systems to ensure adequate adhesion. This allows for more accurate through-hole soldering, as the flux can reach difficult-to-access parts within the circuit board. Additionally, the tool also employs an advanced vision detection asset and automated fiducials to ensure repeatable part placement. This increases the accuracy and repeatability of the placement process. The model can automatically populates parts from over 8 feeder positions and place components as small as 0201. Additionally, the equipment includes a remote monitor that allows the operator to monitor and adjust machine functions as well as the part position from a remote location. S-920N also features real-time traceability capabilities with serialized parts information tracking with the capability of up to 10 million unique serial numbers. The system is easy to maintain due to the modular construction that allows simple replacement of broken parts. In addition, NORDSON / ASYMTEK S-920N has an adjustable mounting design that allows operation on mounting heights of up to 40-inch. This makes the unit highly adaptable to many applications and diverse environments. In conclusion, the NORDONNORDSON S-920N is a component placement and manufacturing machine designed for PC board assembly and manufacturing operations. This tool is capable of fast and accurate component placement with precise vision guidance and automated fiducials. ASYMTEK S-920N also has adjustable mounting options and advanced traceability and serialization capabilities allowing for improved process consistency. This makes S-920N an ideal solution for PC board assembly and manufacturing operations.

There are no reviews yet