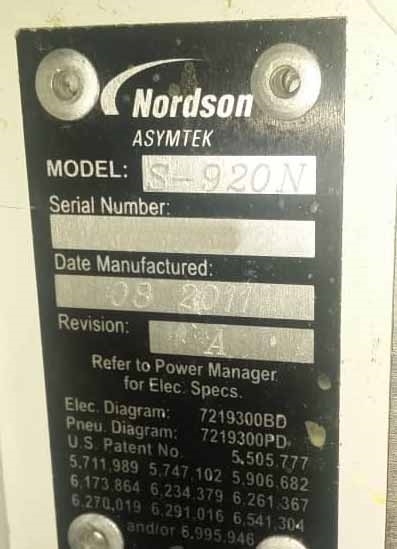

Used NORDSON / ASYMTEK S-920N #9293483 for sale

URL successfully copied!

Tap to zoom

ID: 9293483

Vintage: 2011

Automated fluid dispenser

Revision: A

Operations:

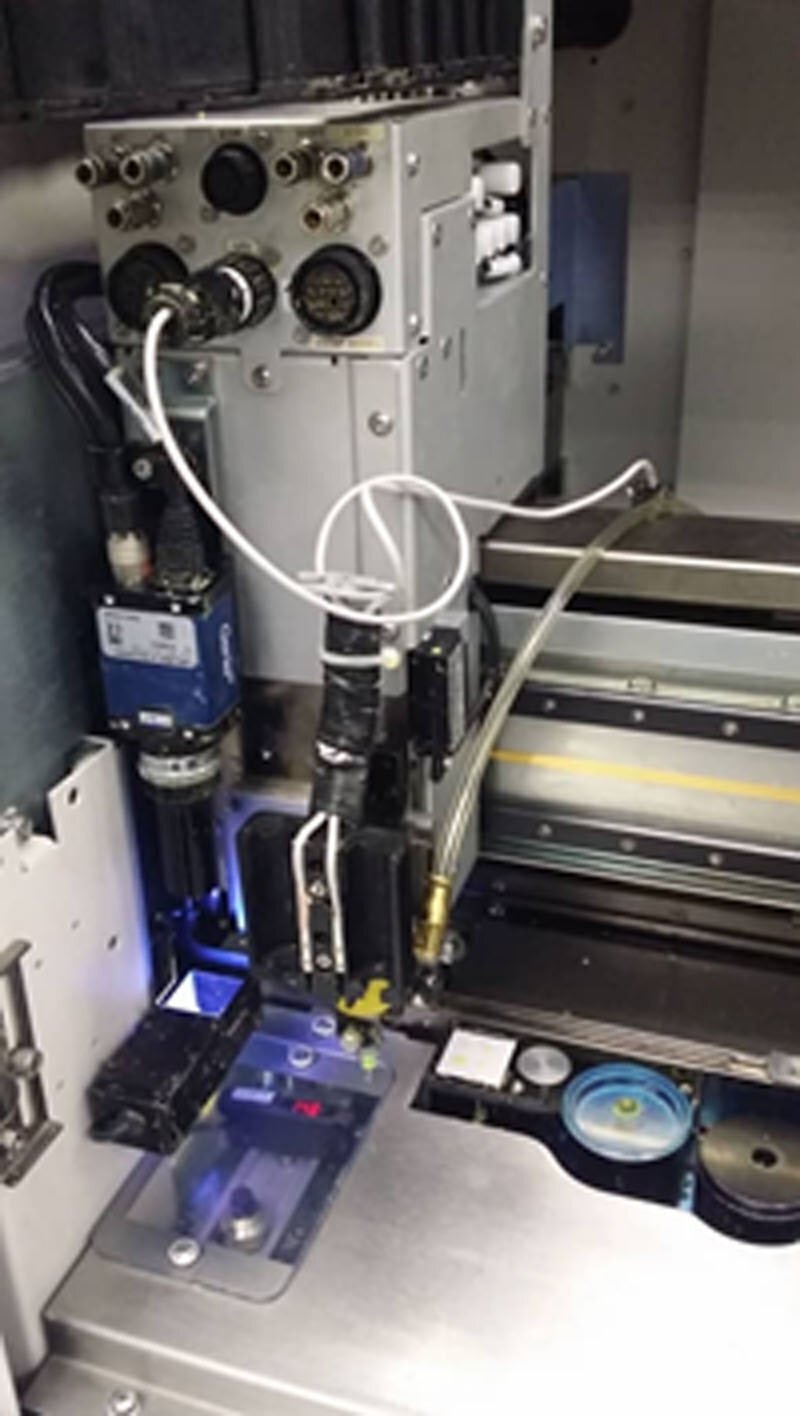

Dual 10cc syringe PLC controlled fluid agitation system

With modified dual ported DV-07 / DJ-9k

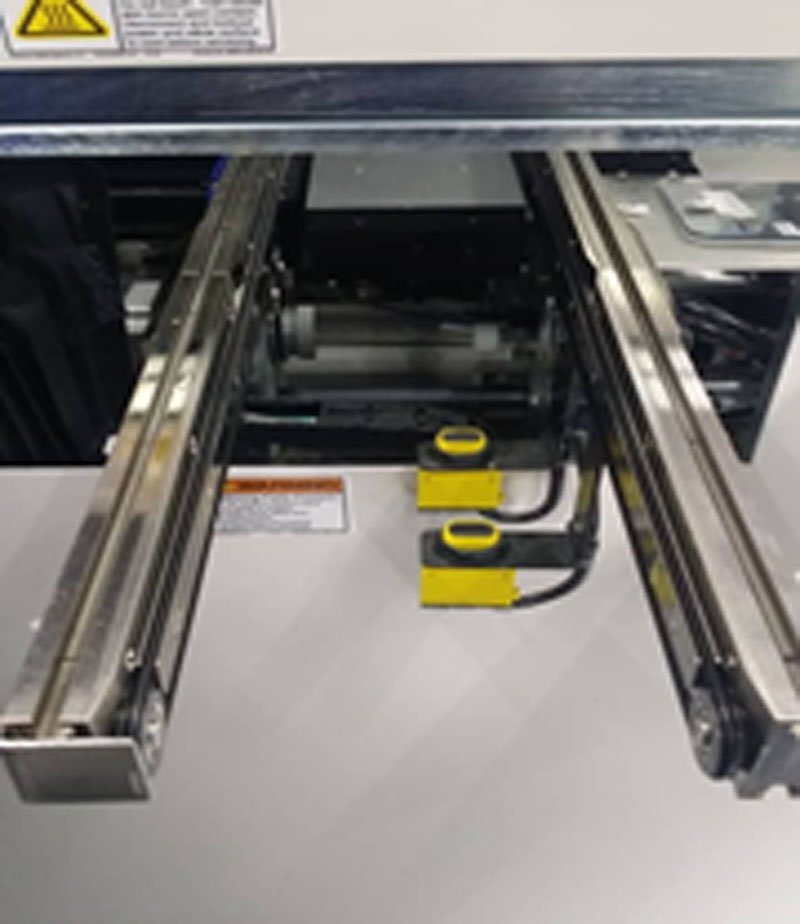

Conveyor:

Input carrier

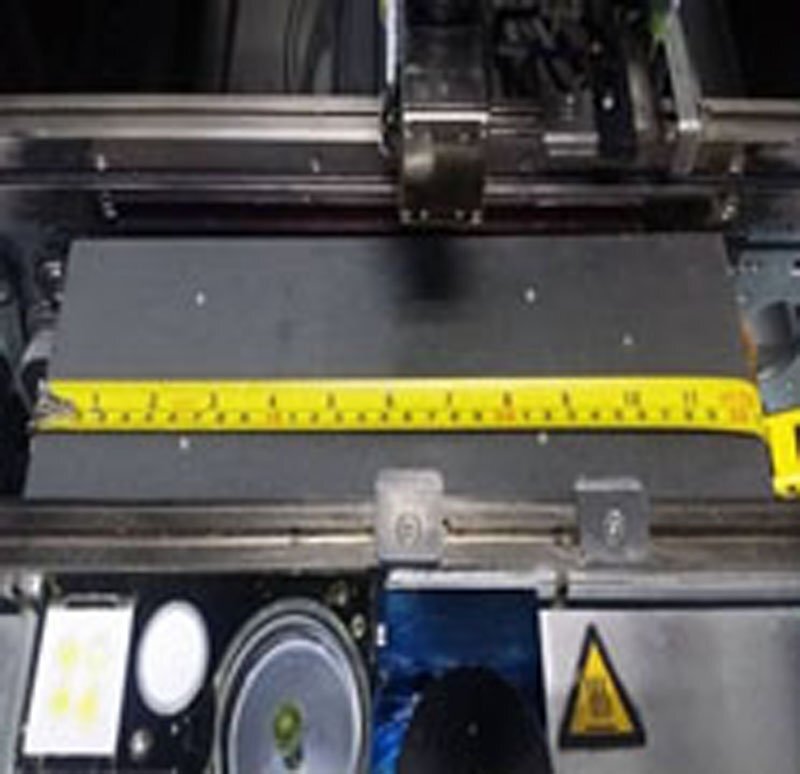

Length: 6"

Width: 4.5"

Heating element: Bottom plate with heater tool

2011 vintage.

NORDSON / ASYMTEK S-920N is a piece of industrial equipment designed for the automated production of PC boards through assembly and manufacturing. It is ideal for the production of circuit boards in high-volume, high-quality production runs. The equipment features an advanced motion control system that provides precise computer-controlled motion. This allows for rapid motion of components and PCB's through the entire production process, and ensures accuracy and repeatability. The motion control unit is capable of coordinating up to 6 axes of motion at once, allowing complex PCBs to be manufactured at a fixed rate with no need for manual intervention. A dual-arm pick and place machine is also integral to NORDSON S-920N. This allows for superior component accuracy and placement accuracy, and works in conjunction with the motion control tool to ensure flawless production. The dual-arm overhead camera asset allows for accurate vision inspection of PCB assemblies during the production process. ASYMTEK S-920N also features a machine access panel. This provides easy maintenance access, and also allows for quick and easy parameter settings, enabling changes to be made at the press of a button. Diagnostics tools are also provided for automated troubleshooting and fault finding if required. The model is capable of handling a variety of components, including axial, surface mount, and dual in-line configurations, and is capable of processing bare substrate as well as fluxless solder coating. It also features a semi-automated cleaning station, which can be used for process verification, and features jet heads for both silkscreening and stencil printing. Overall, S-920N provides an automated manufacturing and assembly solution for PCBs. Its advanced motion control equipment ensures accuracy and repeatability, the dual-arm pick and place system allows for superior component accuracy and placement, and an access panel provides easy accessibility for maintenance and parameter settings. It is a highly advanced unit for the production of high-quality, high-volume runs of PC boards.

There are no reviews yet