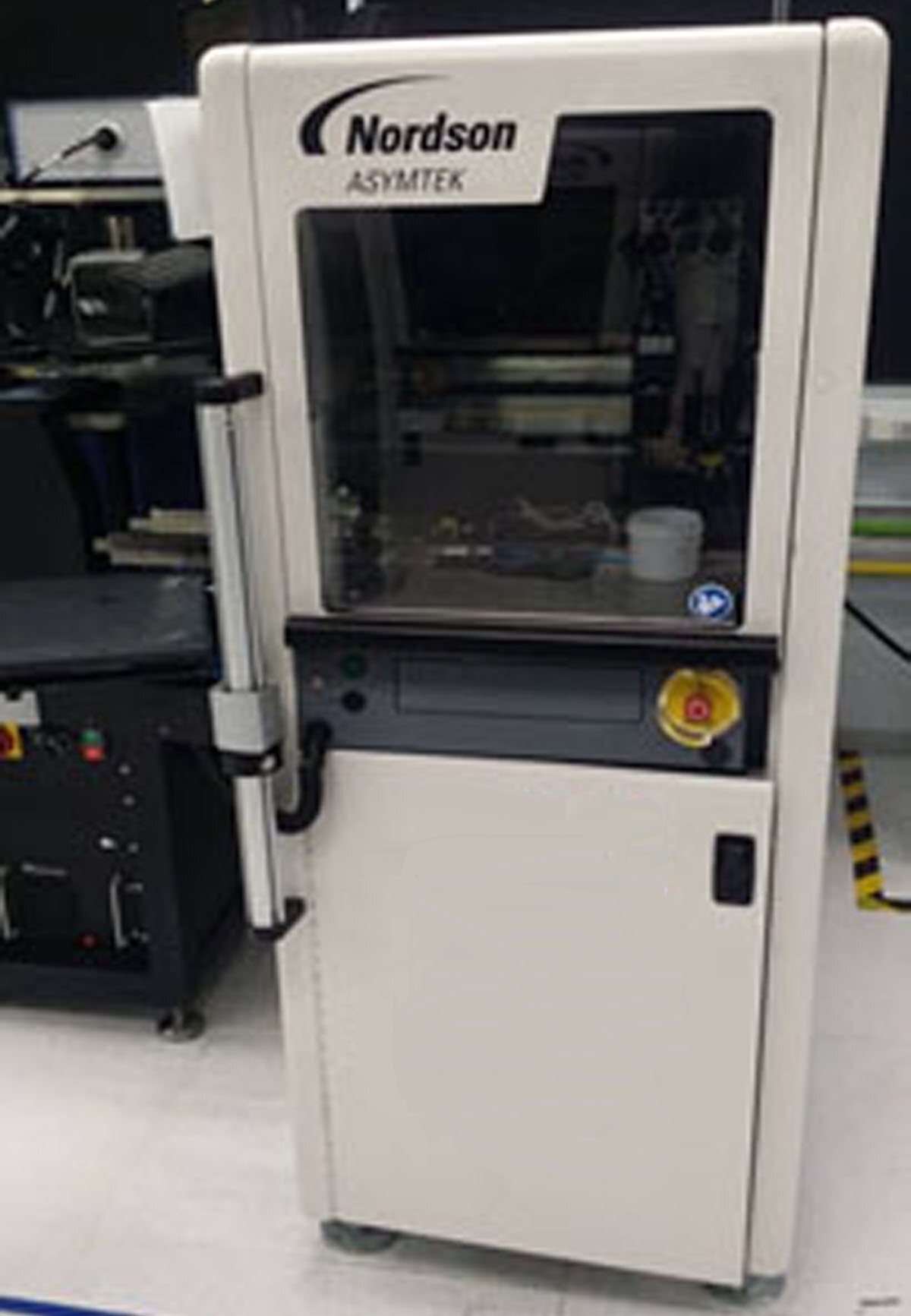

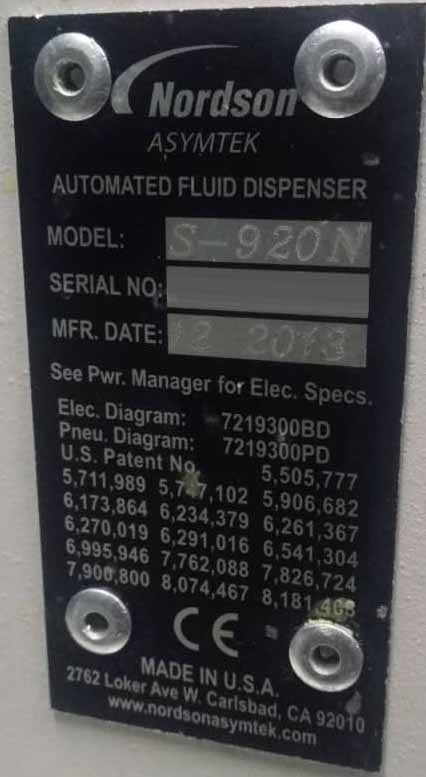

Used NORDSON / ASYMTEK S-920N #9293485 for sale

URL successfully copied!

Tap to zoom

ID: 9293485

Vintage: 2013

Automated fluid dispenser

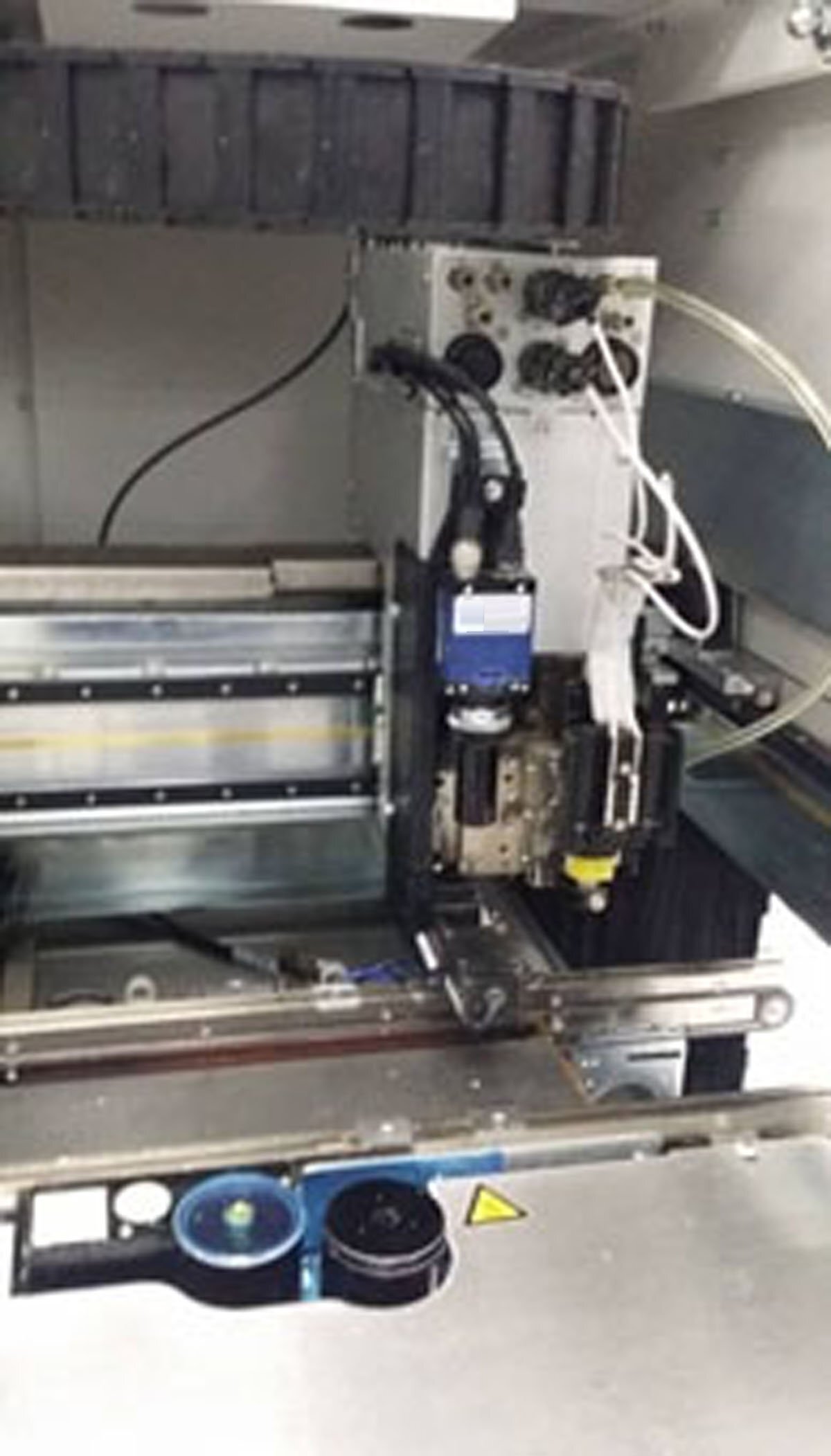

Operations:

Dual 10cc syringe PLC controlled fluid agitation system

With modified dual ported DV-07 / DJ-9k

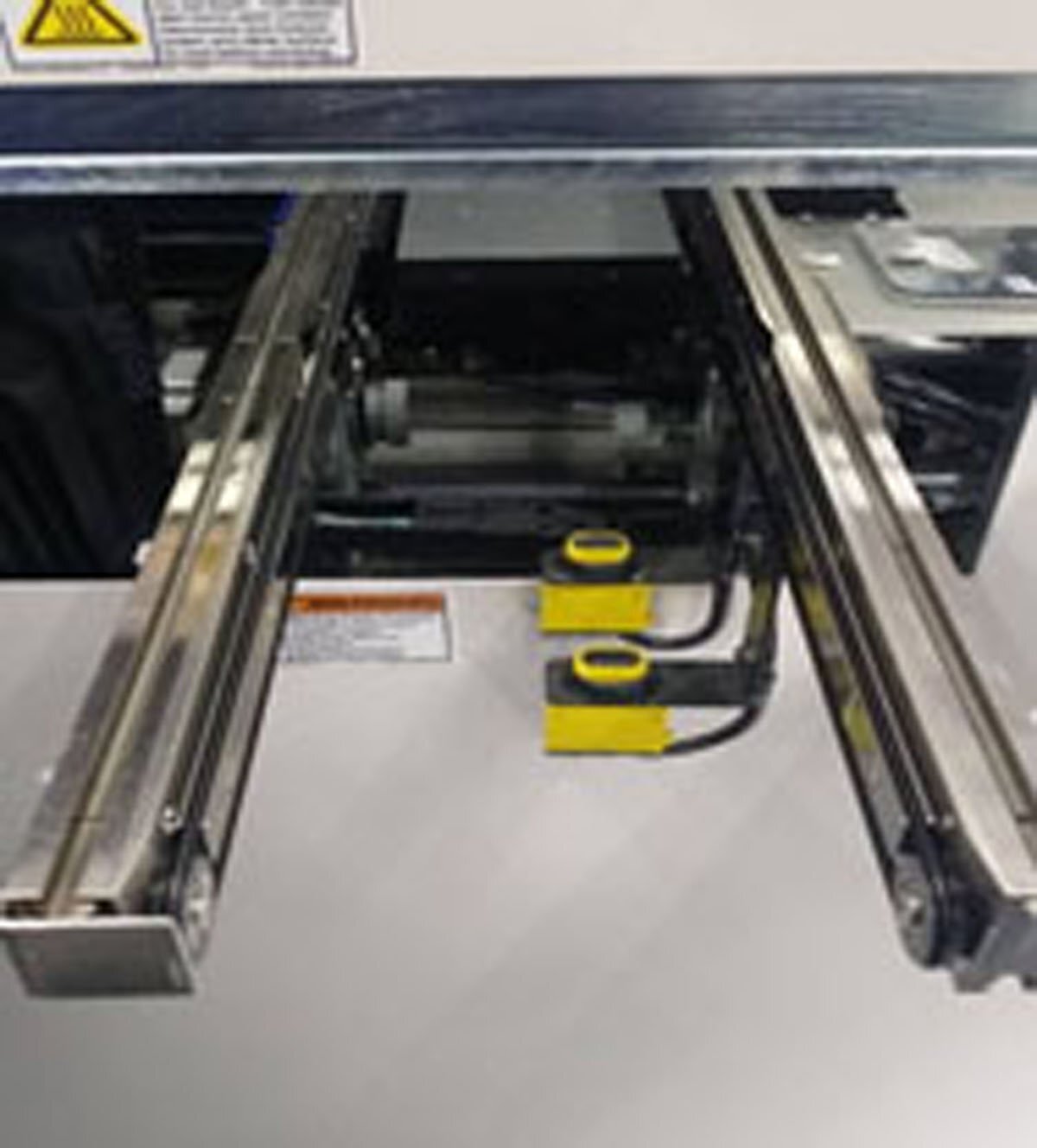

Conveyor:

Input carrier

Length: 6"

Width: 4.5"

Heating element: Bottom plate with heater tool

2013 vintage.

NORDSON / ASYMTEK S-920N is an advanced PC board assembly and manufacturing equipment that offers reliable and efficient operations. It is capable of assembling and manufacturing precisely and efficiently utilizing a wide range of component sizes and varieties. It is made up of four independent application areas, including pick-and-place, conformal coating, dispensing, and printing, and is equipped with integrated vision systems for effective quality control and high productivity. The pick-and-place section utilizes both rotary indexing and linear placement technologies for efficient mounting of the components on the PC boards. The system is designed to handle smaller and more delicate parts, making it especially suitable for high-value components. It is equipped with triple-servo drives for fast, precise placement of the components. Furthermore, the unit utilizes robotics control and advanced CAD/CAM features to provide accurate positioning and delivery of the components. The conformal coating section of the machine is capable of applying conformal coatings to protect components and PC boards from harsh environmental conditions. This section utilizes automated robot arms that are equipped with vision systems for accurate positioning and consistent coating delivery. It also features high-precision temperature control to ensure even coating thickness. This section is expandable and can be used to apply other coatings, such as masking, milling, and rework. The dispensing section of the tool is capable of dispensing solutions, waxes, and other liquids to the PC boards, accurately and reliably. It is equipped with an industrial-grade programming software that enables fast and accurate programming of the dispensing heads, for precise delivery of the materials. Furthermore, it is capable of using different dispensing tips and multiple syringes for efficient dispensing of complex components. Finally, the printing section is used to print circuit diagrams and other markings on PC boards. The asset is equipped with a high-end inkjet printer for fast and accurate printing of the desired markings on the boards. It is also equipped with a vision model for quality control and correction of errors in the printing process. In summary, NORDSON S-920N is an advanced PC board assembly and manufacturing equipment designed for efficient and reliable operations. It consists of four distinct application areas that are equipped with robotics and vision systems for enhanced productivity and quality control. It is capable of handling a wide variety of components and can be expanded to accommodate additional processing needs.

There are no reviews yet