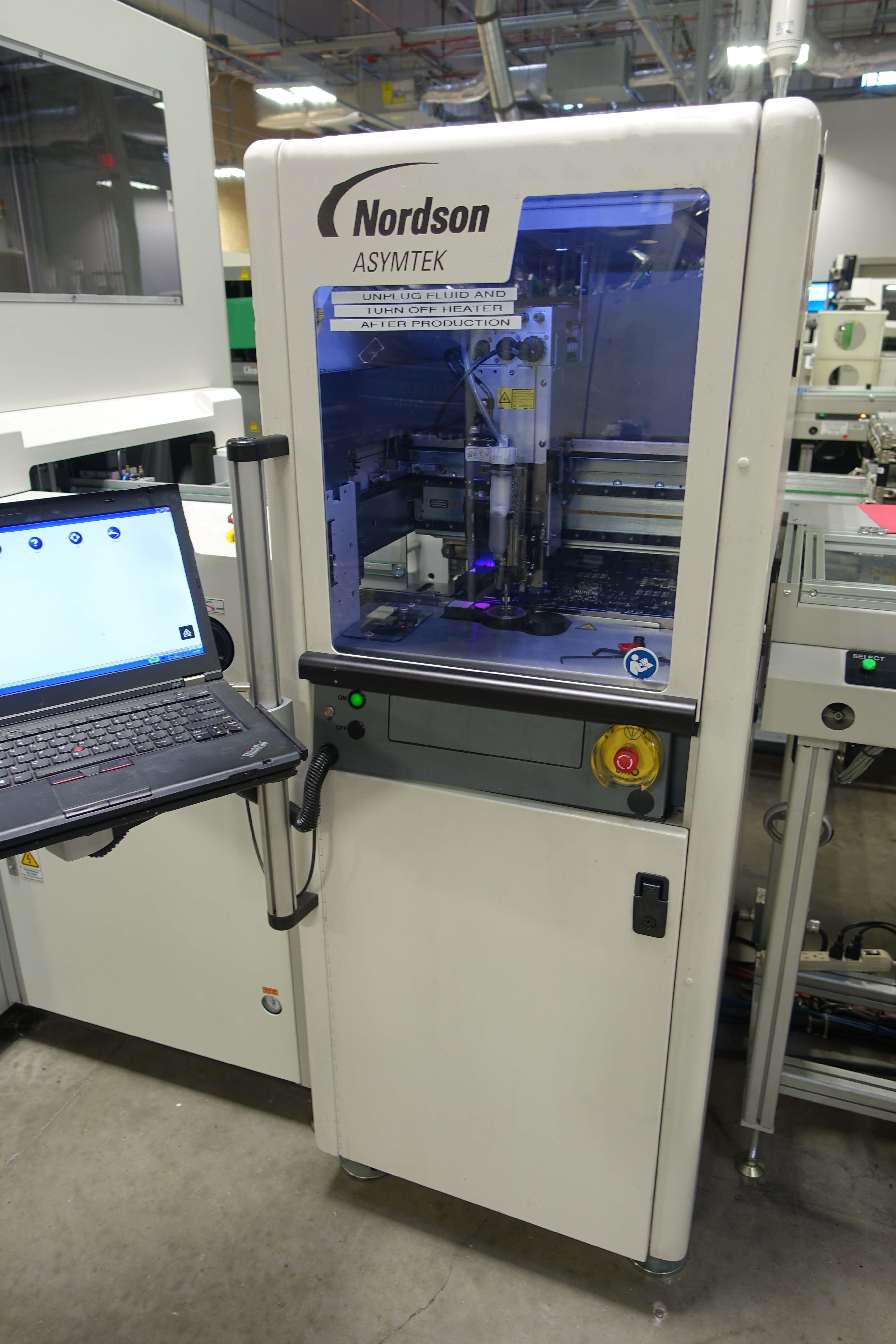

Used NORDSON / ASYMTEK S-922N #9354584 for sale

URL successfully copied!

Tap to zoom

ID: 9354584

Vintage: 2013

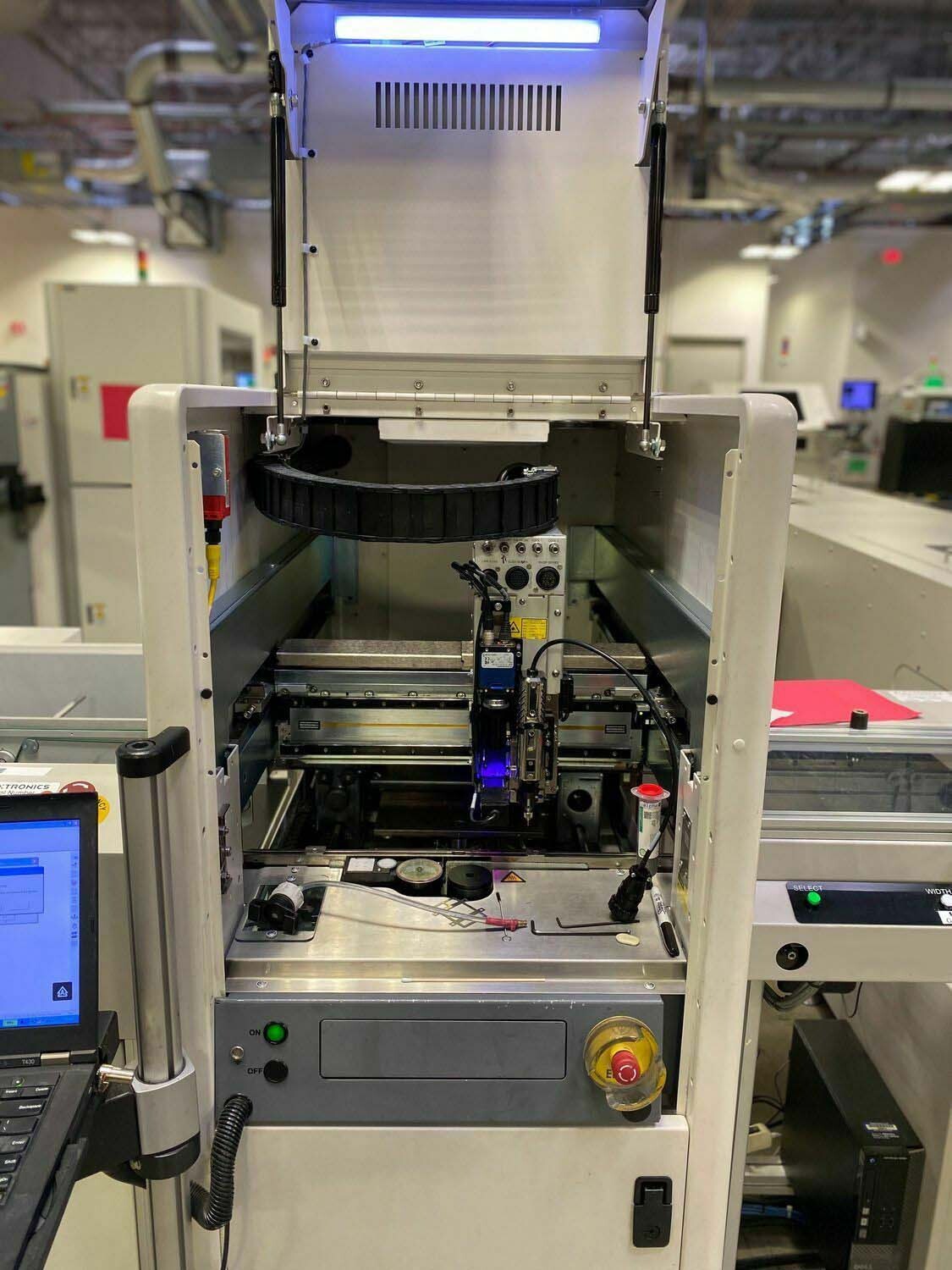

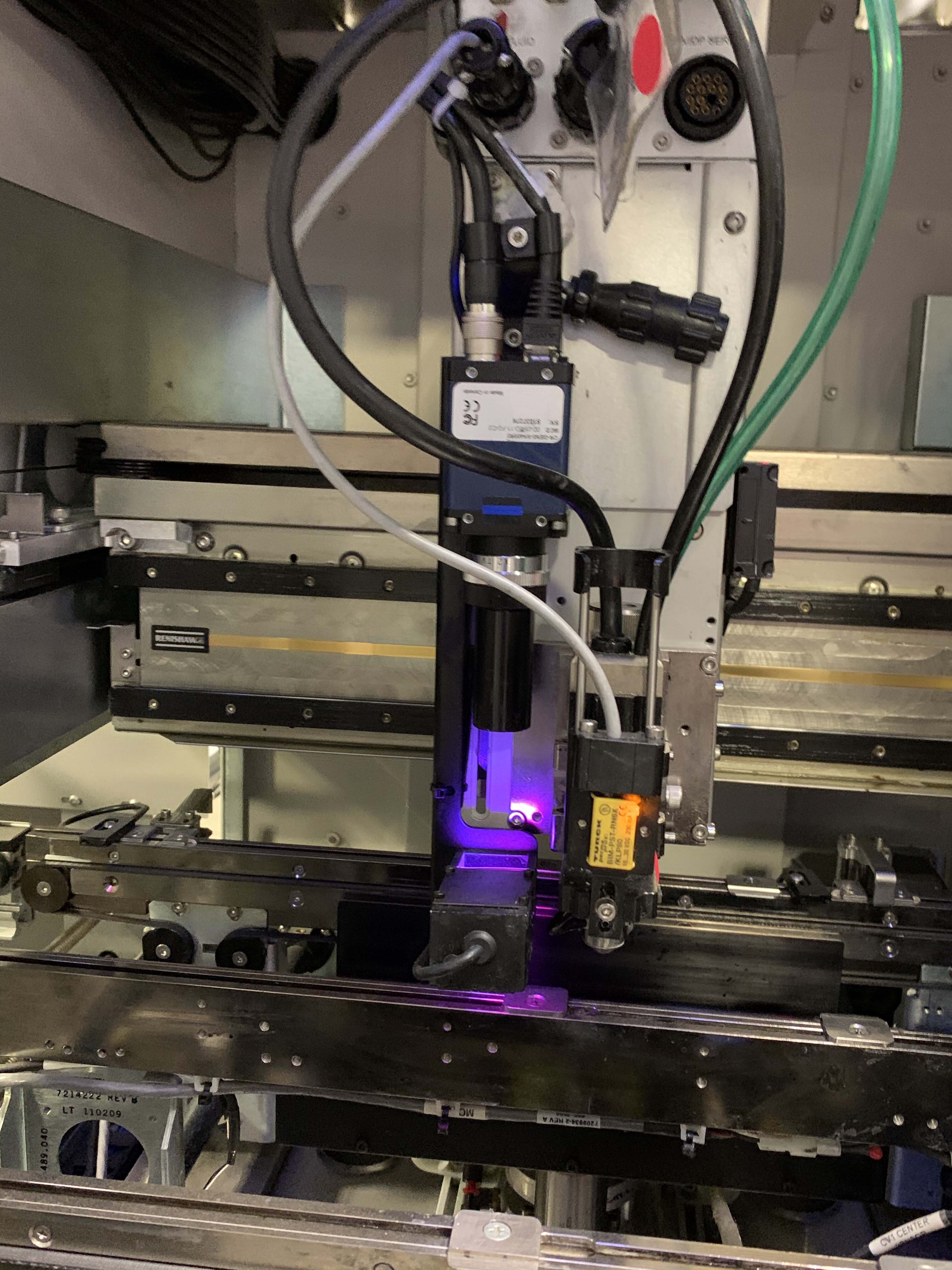

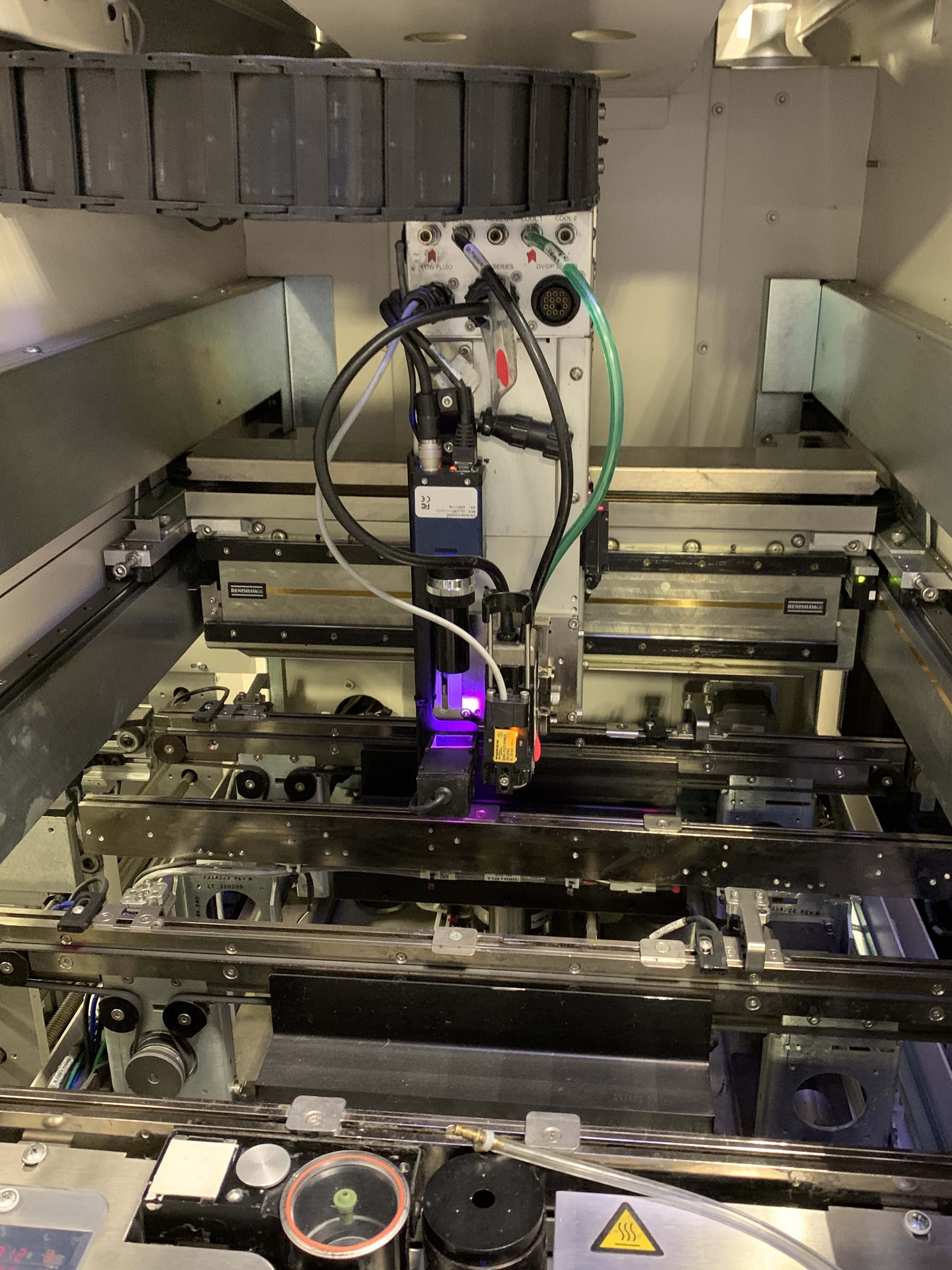

Automated fluid dispenser

Motion system:

X-Y Placement accuracy: ±0.050 mm, 3 σ

Z Accuracy: ±0.025 mm, 3 σ

X-Y Repeatability: ±0.025 mm, 3 σ

X-Y Acceleration: 1 g Peak

X-Y Velocity: 1 m/s Peak (40 in./s)

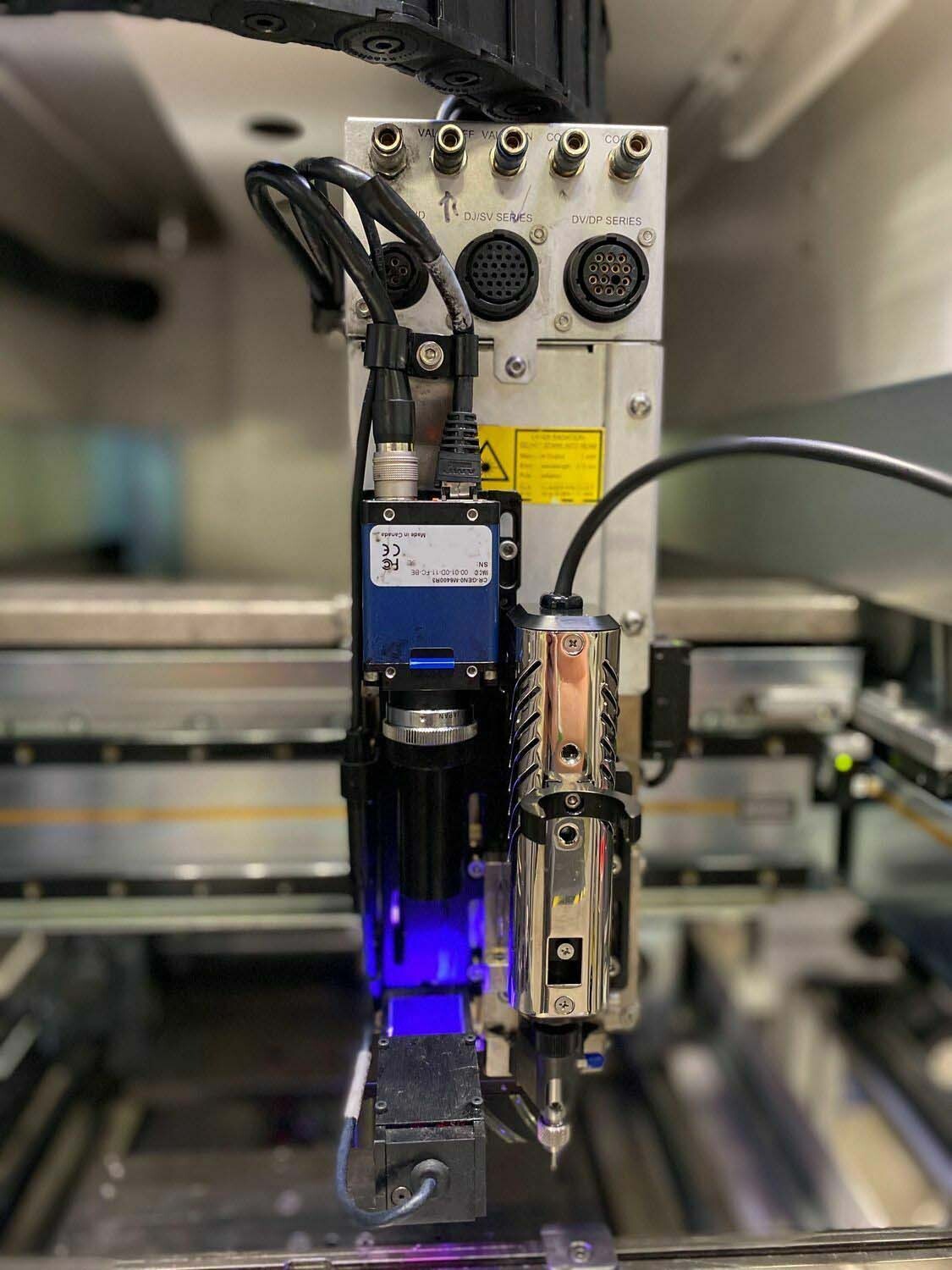

Vision and lighting:

Camera resolution: 640 x 480 Pixels

Field of view: 7.0 x 5.0 mm (0.28 x 0.20 in.)

Lighting: Red / Blue LED

With 255 independent light levels for each color

Computer:

Laptop with windows operating system

Dispense area (X-Y):

339 x 410 mm (13.3 x 16.1 in.)

Conveyor:

Maximum board / Carrier length:

One station: 340 mm (13.4 in.)

Three stations: 320 mm (12.6 in.)

Minimum board / Carrier length: 25 mm (1.0 in.)

Maximum board / Carrier width:

Single lane: 535 mm (21.1 in.)

Dual lane: Up to 228 mm (9.0 in.)

Minimum board / Carrier width: 34 mm (1.3 in.)

Maximum board / Carrier thickness: 12 mm (0.5 in.)

Maximum overboard clearance: 30 mm (1.2 in.)

Under board clearance: 2.75 mm (0.11 in.)

Maximum load capacity: 2 kg (4.4 lbs.)

Operation modes:

Automatic (SMEMA)

Manual

Pass-through

Belt types:

ESD O-ring

ESD High-temp 6-mm flat belt

ESD High-temp 4-mm flat belt

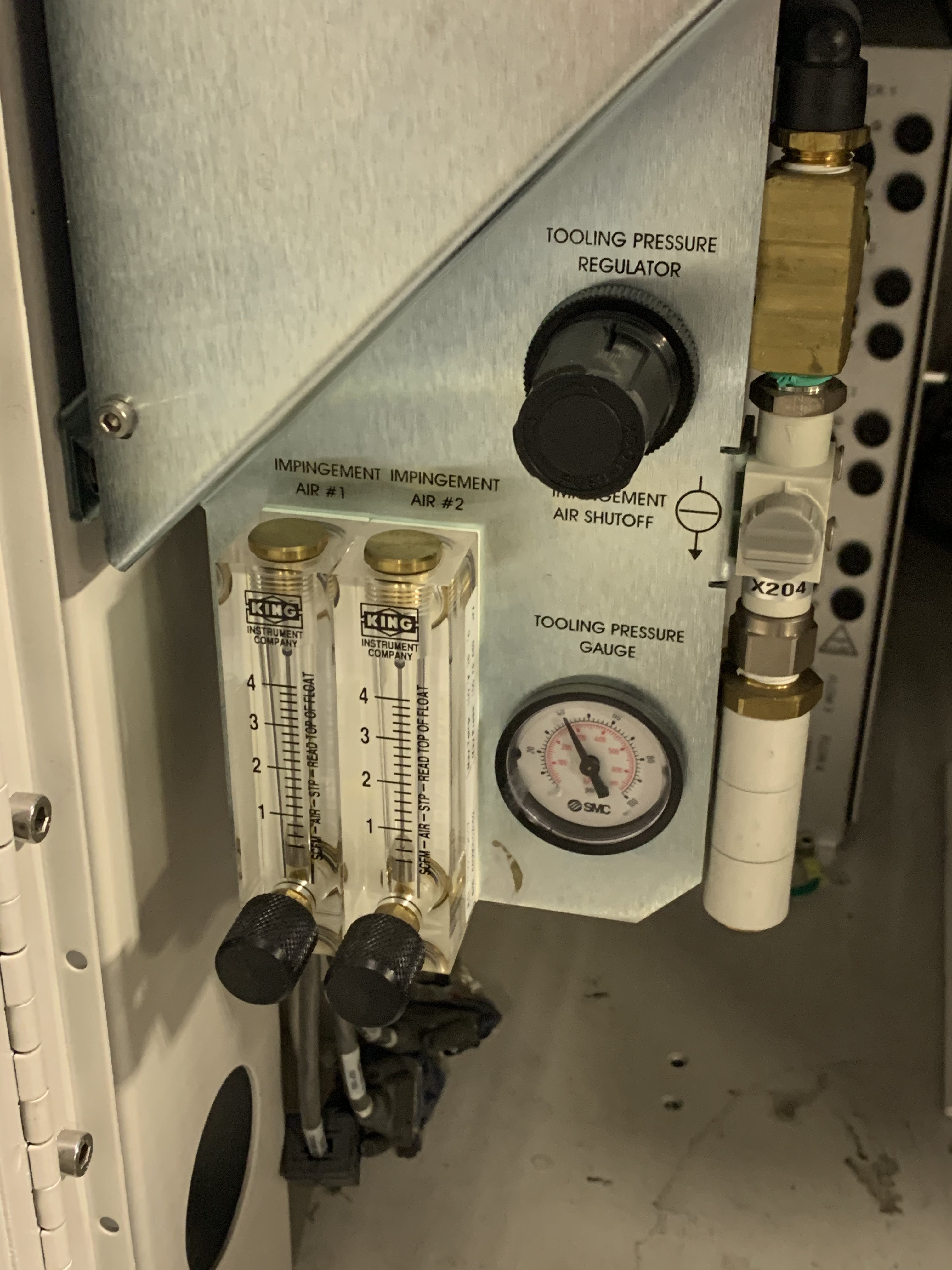

Facilities requirements:

System footprint: 600 mm wide x 1321 mm deep (23.6 x 52.0 in.)

Two heat stations: 850 x 1321 mm (33.5 x 52.0 in.)

Three heat stations: 1100 x 1321 mm (43.3 x 52.0 in.)

Air supply: 689 kPa (6.8 atm, 100 psi)

Power supply: 200-240 VAC, 47-63 Hz, Single phase, 30 A

2013 vintage.

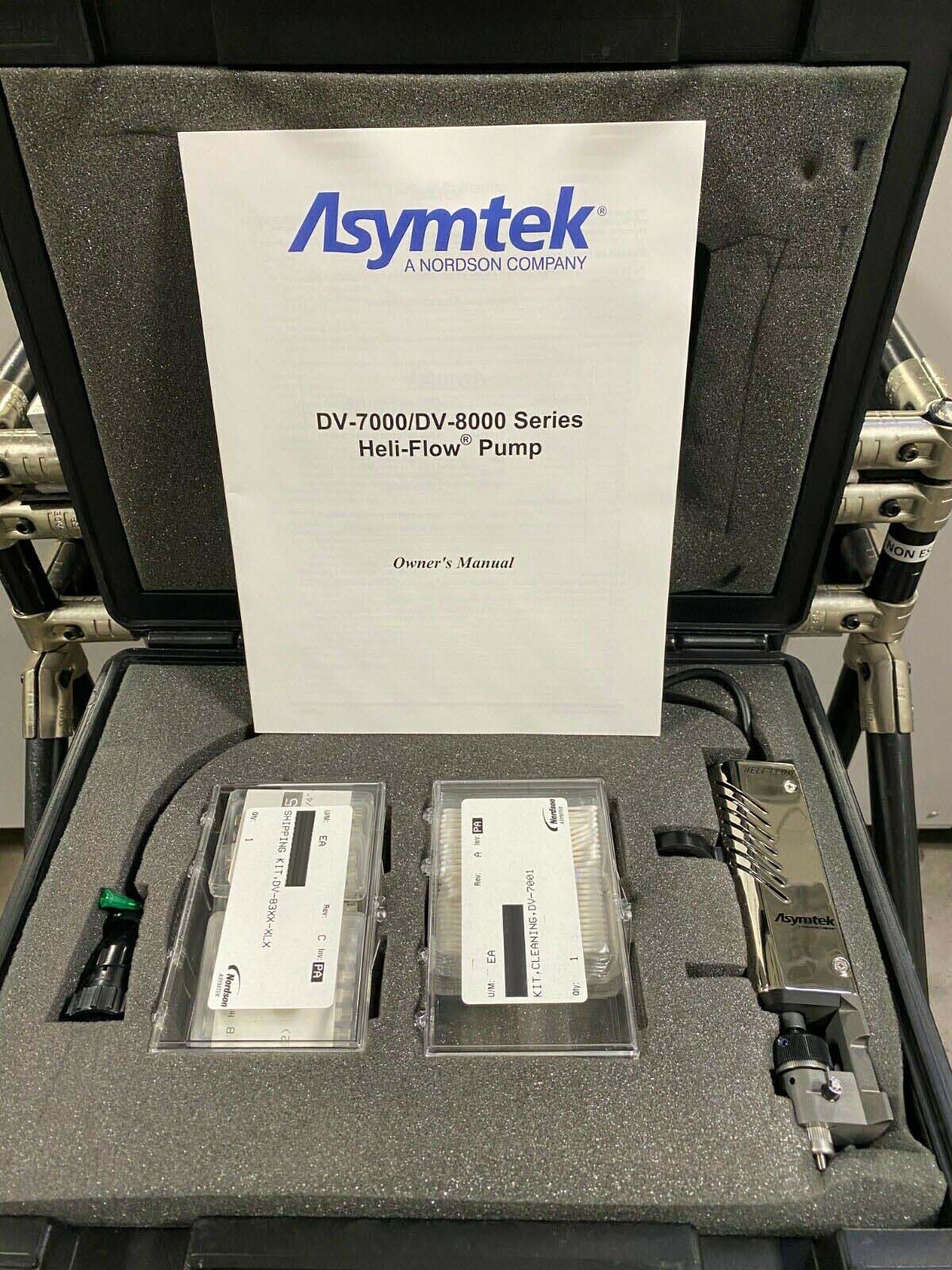

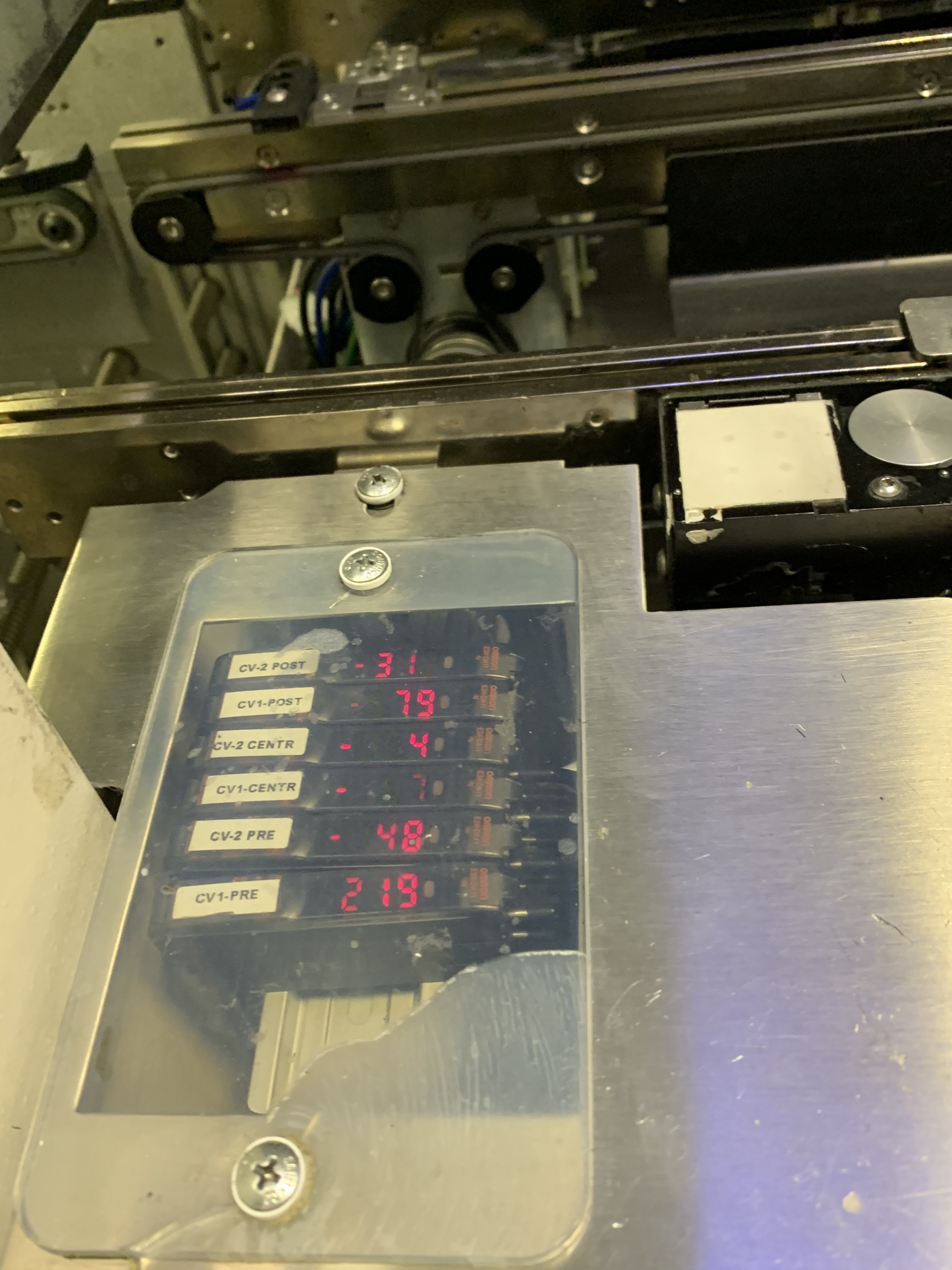

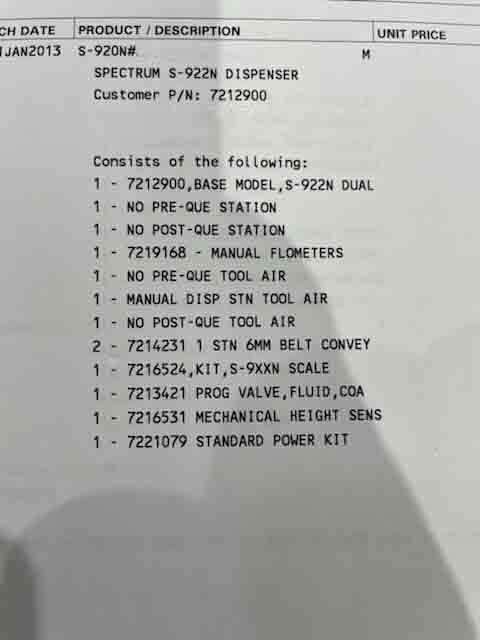

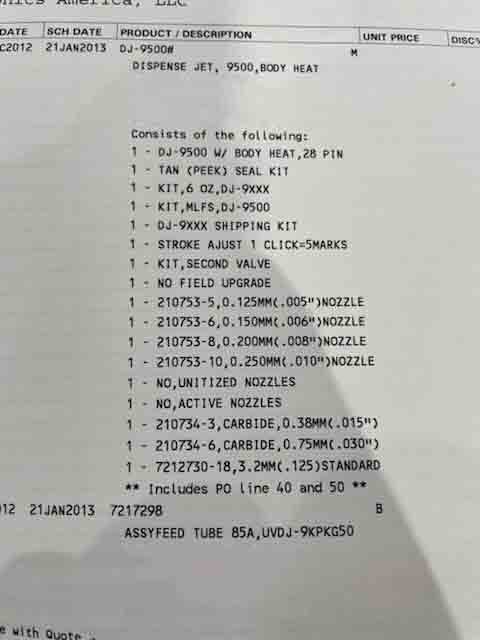

NORDSON / ASYMTEK S-922N is a fully automated, multiple station, pc board assembly and manufacturing equipment, designed to produce high quality SMT and dip PC board assemblies. The advanced design allows for the integration of multiple process technologies and station configurations in a single platform. NORDSON S-922N features a number of advanced technologies, such as an enclosed, part-tracing, double-track conveyor belt, high-speed digital network dispensers, dual-lane SMT fed component placement systems, as well as In-line AOI vision and component presence detection components. It also provides Class A1 inspection technology for each component, and automatic component sorting capabilities. ASYMTEK S-922N operates on an advanced control system, featuring several automated operational functions as well as interactive diagnostics. The unit can be configured with two, four, and six-stage linear component transport and placement, with each stage featuring its own independently controlled linear motors to ensure optimum placement accuracy. S-922N also features an improved mechanical design for maximum reliability and efficiency, including an extendable indexer head with multiple nozzle options, as well as a pneumatically operated assemblies for smooth and precise movement between stages. NORDSON / ASYMTEK S-922N's advanced manufacturing software enables on-the-fly job setting, serialization, as well as real-time job management. NORDSON S-922N is designed to meet high quality production standards and offers a variety of customization options including component verification, open cavity, soldering, component marking, and wire sizing. Additionally, ASYMTEK S-922N provides a variety of power supply options to meet any power requirement, including single-phase, three-phase, AC or DC, and dual voltage options. S-922N is designed to provide a high-performance, cost-effective solution for pc board assembly and manufacturing. The advanced technologies, control machine, and multiple customization options ensure that the tool can easily meet the most demanding production needs.

There are no reviews yet