Used NORDSON / ASYMTEK SD-960 #9361811 for sale

URL successfully copied!

Tap to zoom

ID: 9361811

Vintage: 2018

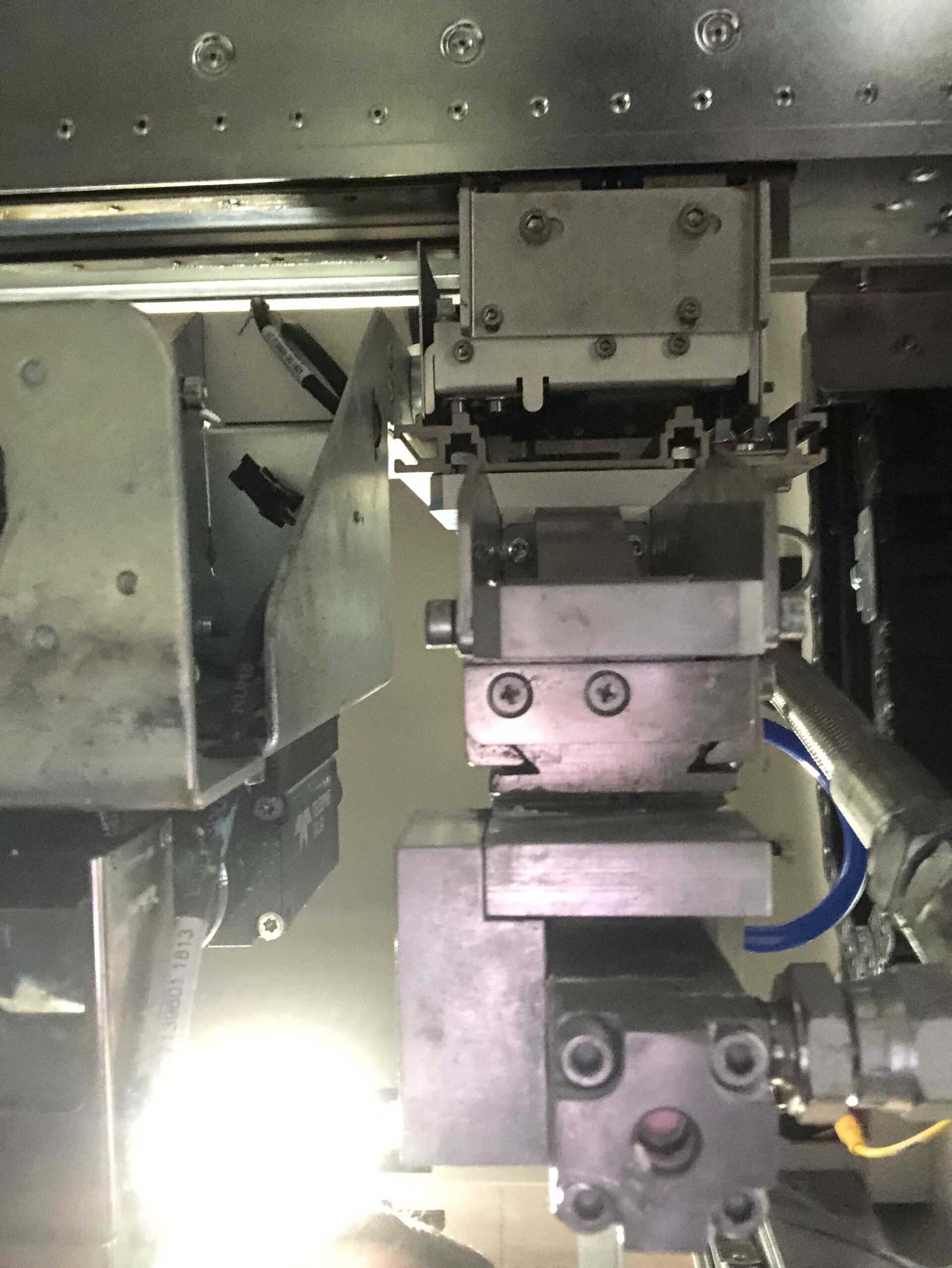

Fluid dispensing system

For potting type

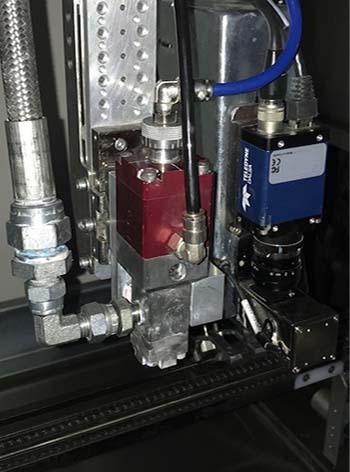

High pressure valve SB300

Laser height sensor

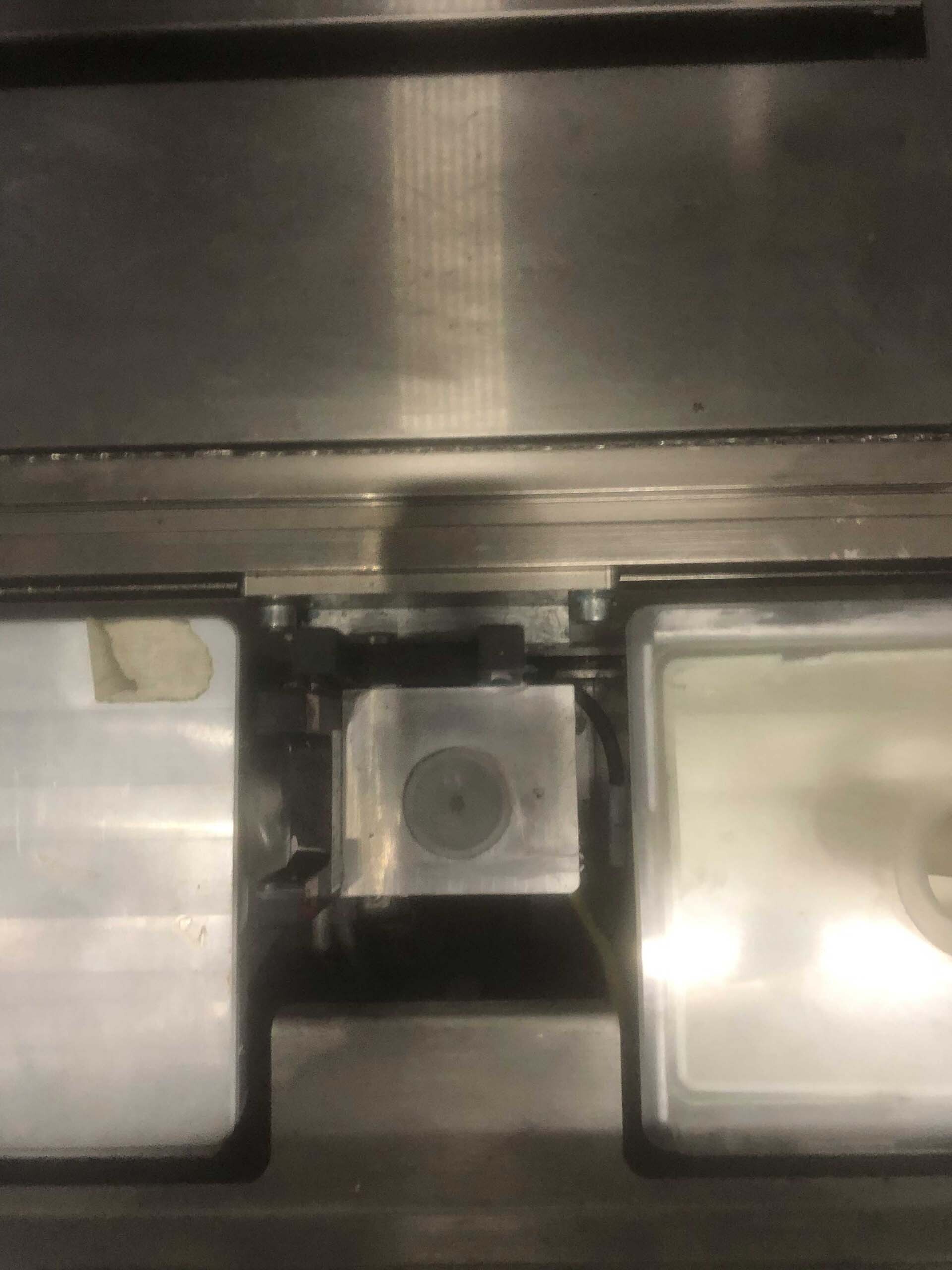

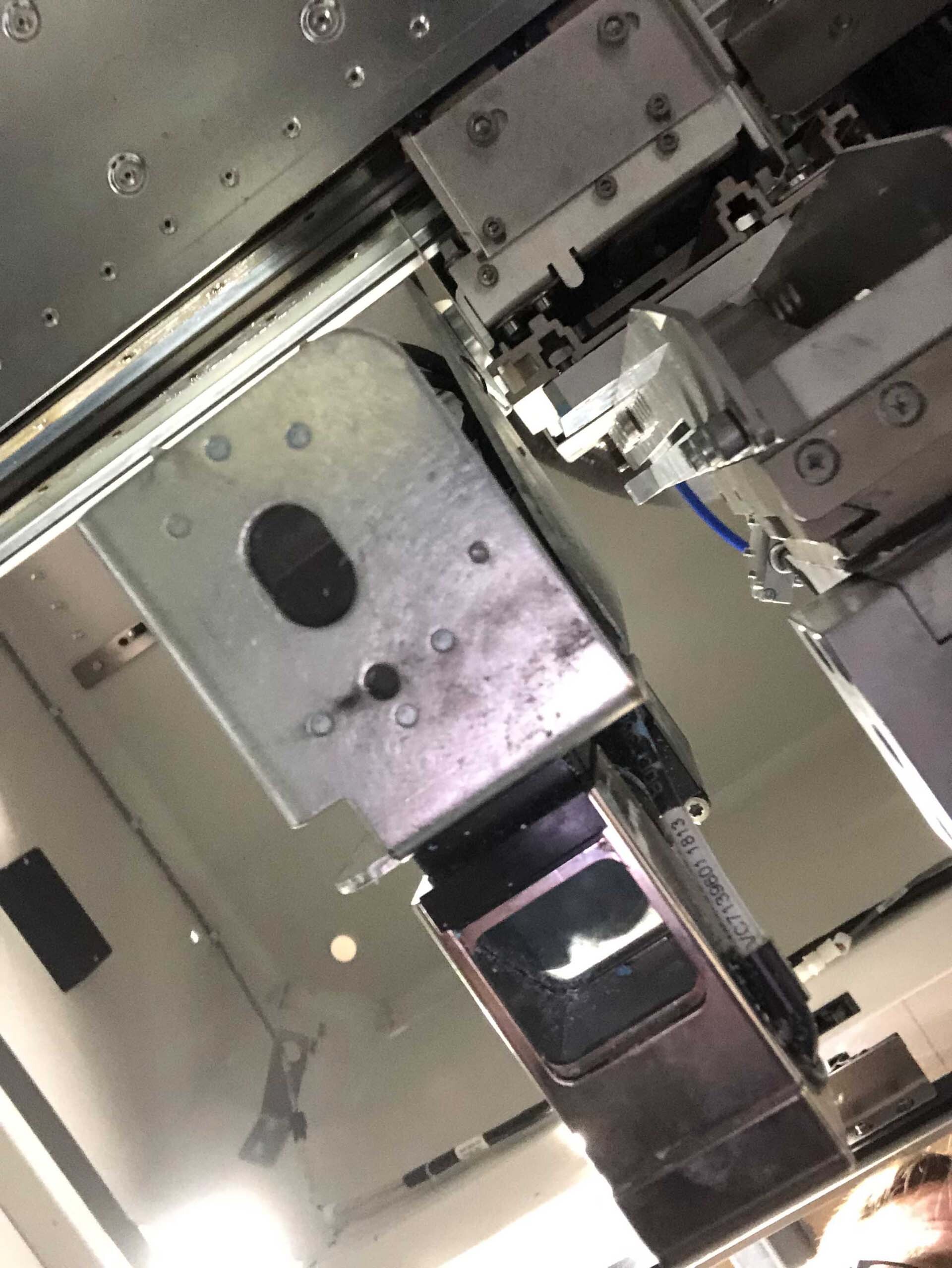

Chain type conveyor with stop pin

Product sensor

Motor driven width adjustment: 35-475 mm

Payload: 5 Kg

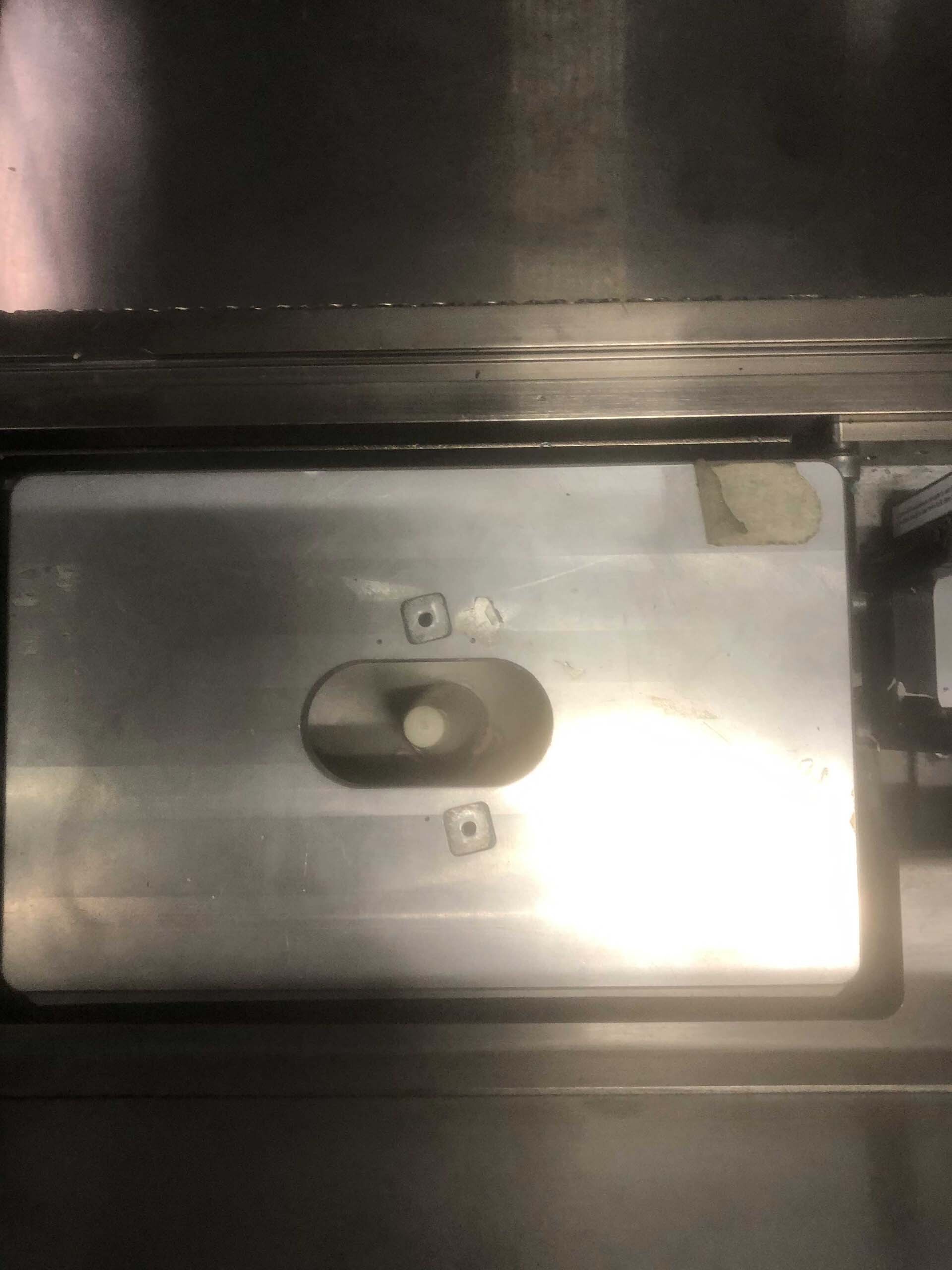

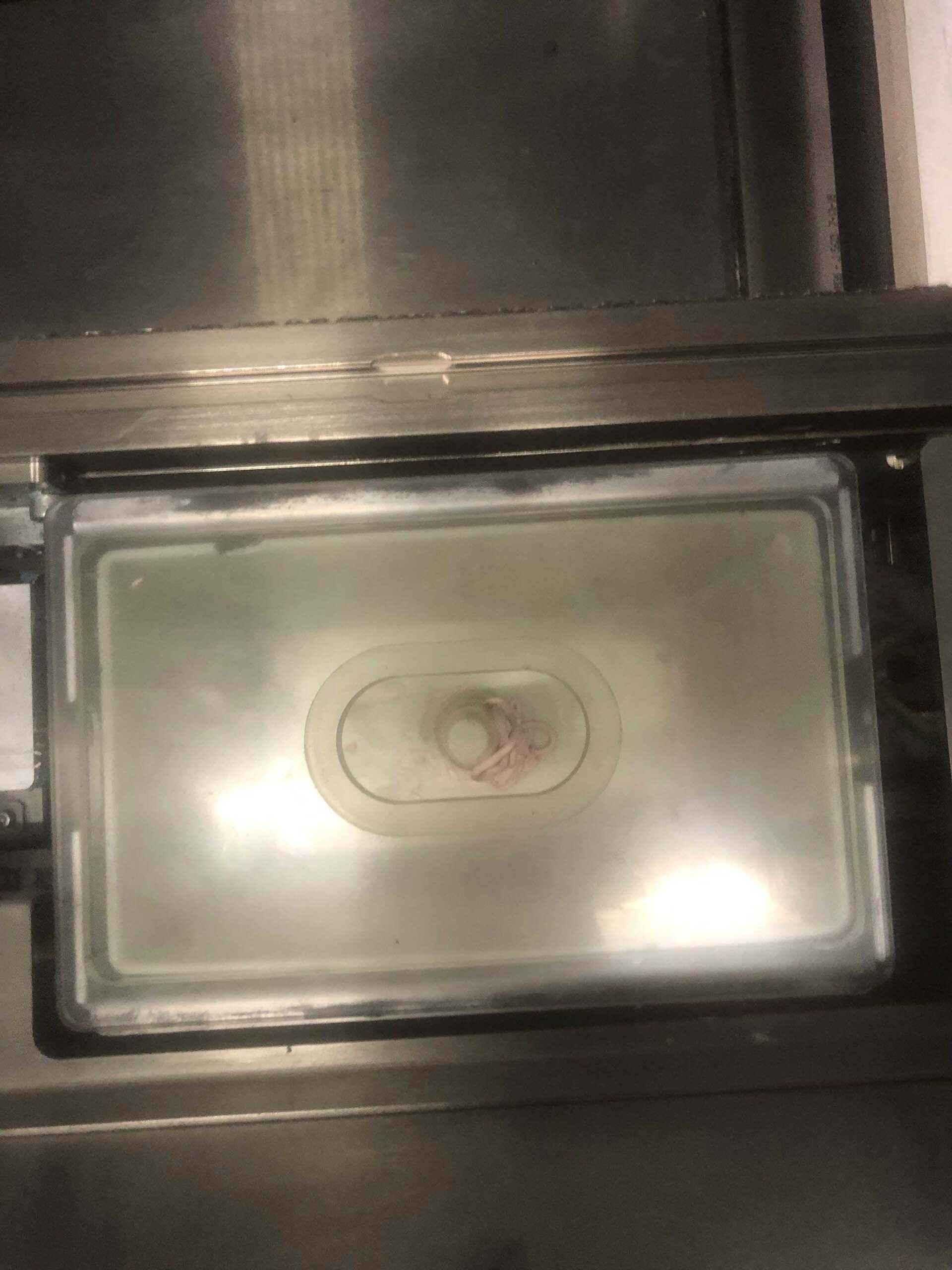

Dispense area X, Y: 500 x 440 mm

Pattern recognition system (Camera) with lighting

Door interlock control

Light beacon with audible alarm

Emergency stop button front and rear

Main circuit-breaker located rear machine

Exhaust chimney with pressure security valve

Stainless steel interior

Dark light

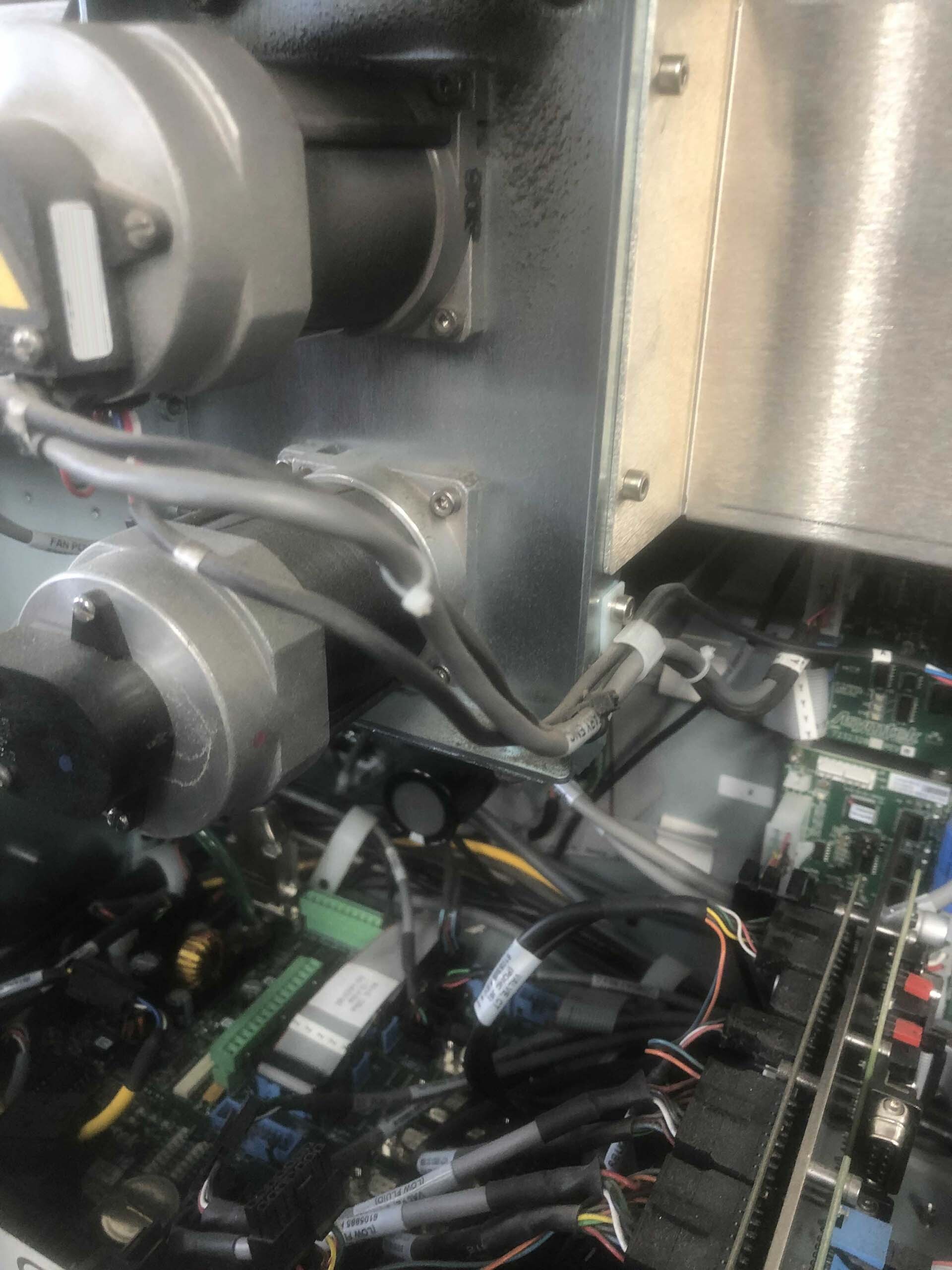

Laptop with Pentium processor

User interface: Keyboard and screen

Adjustable height computer arm

Air supply: 6-2 bar

Color: RAL 9002

Operating system: Windows 7

SMEMA Communication

CE Marked

Power supply: 230 V, 10 A, 50-60 Hz

2018 vintage.

NORDSON / ASYMTEK SD-960 is a top-of-the-line PC board assembly and manufacturing equipment for high-volume production. This system combines a full range of advanced dispensing and placement solutions in a single box. The unit can handle up to 1,250 boards per hour, which make it suitable for both small- and large-scale production. It offers a full complement of component placement, including surface mount, chip-on-board, and through-hole technologies. The dispensing technologies are capable of accurate and precise production with minimal material wastage, and conformal coating. NORDSON SD-960 is designed to meet the highest standards of quality. It utilizes a vision machine with 3 camera packages comprised of color, red, and infrared cameras. This sophisticated vision tool helps ensure accurate placement of components and repeatable results. Furthermore, the asset is equipped with advanced wafer edge reader capability for tape and reel management. This feature helps optimize material usage by providing a precise measurement of the amount of tape or reel remaining on the wafer. ASYMTEK SD-960 has a range of software features to provide operators with more control over the placement process. This includes batch monitoring and production reporting options that provide real-time information on model output and performance. The equipment also has built-in self-diagnostic and maintenance features that help simplify service requirements. Additionally, a library of recipes can be stored on the system for quick retrieval and optimization of production runs. SD-960 also features an easy-to-use interface. This helps make the unit more intuitive and easy to use. Furthermore, the full touch-screen control panel provides operators with increased visibility and flexibility, enabling them to quickly access different dispensing, coating, and placement methods and parameters. Additionally, the machine supports a range of virtual machine intelligence (VMI) capabilities, including automated material replenishment, automated material loading, and diversion capabilities. Overall, NORDSON / ASYMTEK SD-960 pc board assembly and manufacturing tool is one of the best on the market today. With its advanced technologies, sophisticated vision asset, and easy-to-use interface, the model is capable of providing high-quality results in a cost-effective manner. Furthermore, its range of software features enables operators to optimize production runs and simplify machine maintenance requirements.

There are no reviews yet