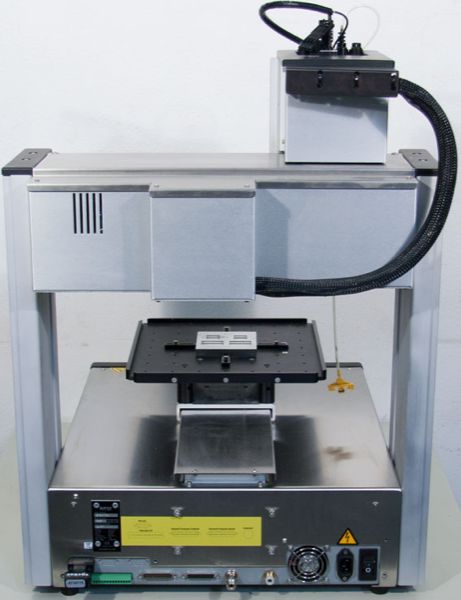

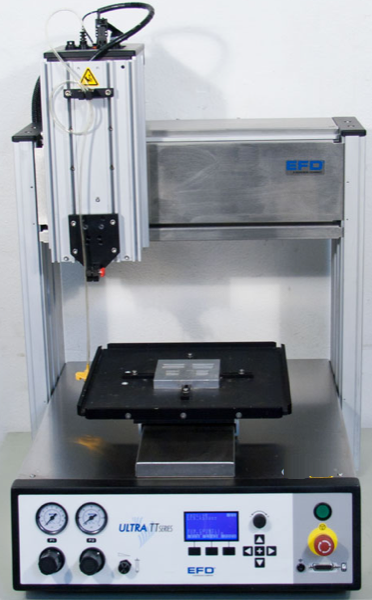

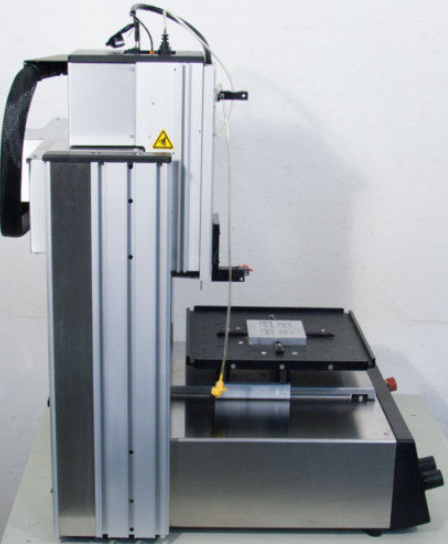

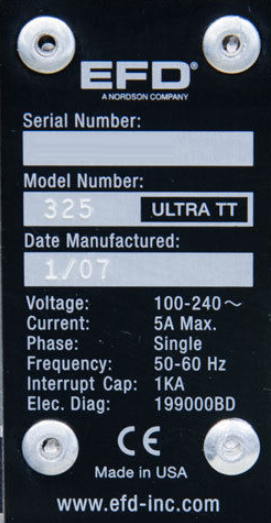

Used NORDSON-EFD 325 Ultra TT #168394 for sale

URL successfully copied!

Tap to zoom

ID: 168394

Vintage: 2007

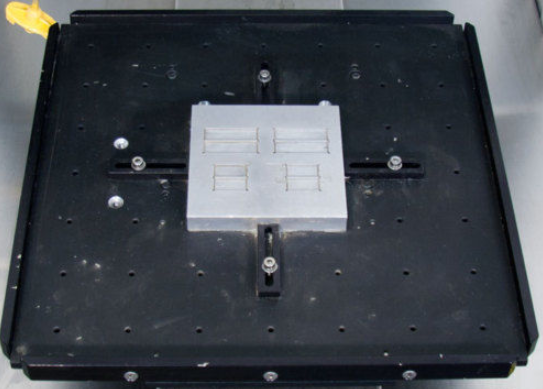

Automated dispensing system

Specifications:

Resolution: 10 µ

Repeatability: 25 µ

Maximum speed: 500 mm/sec

Acceleration: 0.25 g

Mechanical configuration: H-Bridge de-coupled axes

Control method: Closed loop DC servo

Drive system: Cable drive

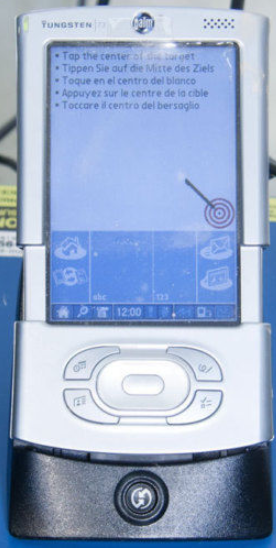

Programming interface: Front panel buttons, palm handheld

Program capacity: 100

Point capacity: 10000

General purpose I/O: 16 Inputs / 16 Outputs

Discrete I/O: 1 Analog input / output, 4 inputs / 4 outputs, (2) solenoid drivers

External communications: 1 RS232 / 1 Pal

Height sensor

Tip change reset

Current consumption: 320 Watts

Input voltage: 100 VAC ~ 240 VAC (±10%)

Dispense controller: Integrated

Number of dispense valves/syringes: 1, 2 or 3

Patterns: Lines, circles, arcs, continuous paths, potting and dotsdot

Height sensor for critical deposit control

Front panel control: Offset, jogging & program select

Power requirements: 100-240 VAC~, 5 A, single phase, 50-60 Hz

2007 vintage.

The NORDSON EFD NORDSON-EFD 325 Ultra TT is a pc board assembly and manufacturing equipment designed to supplement manual soldering operations. Its advanced features enable the system to handle a variety of components, ranging from three- to eight-leaded parts to surface mount devices, and it can be integrated with other soldering systems as well. The unit features an intuitive graphical user interface and an automatic color detection tool. Additionally, the UltraTT is designed to provide a reliable solution for both through-hole and SMD components. The machine is equipped with a dynamic, self-leveling head that prevents expending heat on incorrect parts and includes an extendable arm. This arm allows for a wider reach and better placement of components. Included is a temperature control tool to ensure accurate and tolerances are met. The software also has a built-in auto-programming capability for hassle-free operation; for example, the operator can load part assemblies with just a few simple steps. The asset's integrated line visualization tool provides a view of what's going on in real-time. Additionally, to optimize results, the model includes a variety of engineering options such as board heating, air nozzles, solder paste printers, and robot systems, while it also supports the most up-to-date connectivity options such as Ethernet and USB. This allows the equipment to be integrated with multiple machines, providing flexibility in terms of part design and complexity. Due to its comprehensive features, the NORDSON EFD 325 Ultra TT is designed to reduce production cycle times and cost. It features power-saving technology to minimize energy costs and reduce environmental impact. Furthermore, the system is designed to ensure production quality by providing efficient inspection, while also offering programming and diagnostics to ensure consistent performance. Ultimately, it is an efficient, reliable, and environmentally friendly solution for circuit board assembly and manufacturing.

There are no reviews yet