Used NORDSON / YESTECH F1 #9286408 for sale

URL successfully copied!

Tap to zoom

ID: 9286408

Automated Optical Inspection (AOI) system

High-speed PCB inspection

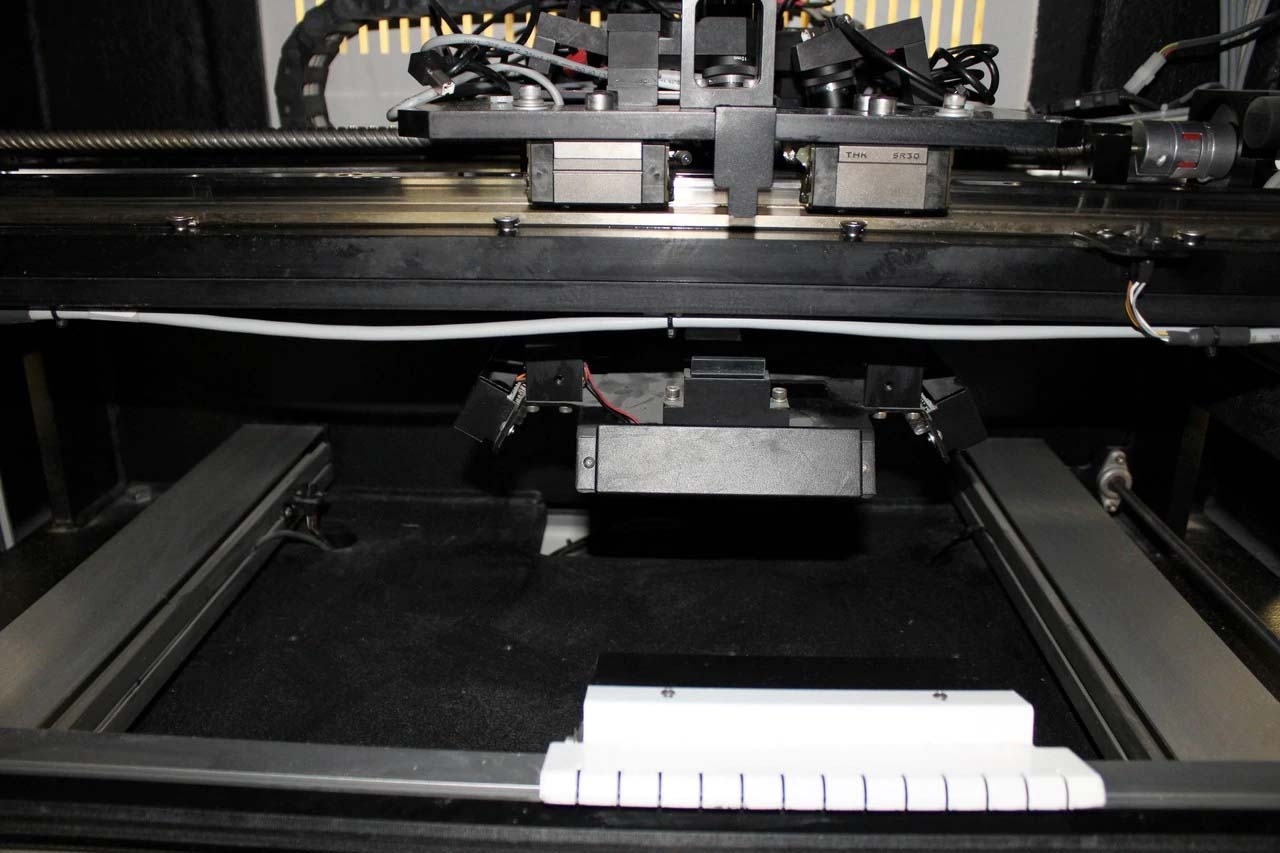

(2) Top-down viewing cameras

Four side viewing cameras

Inspection capabilities:

Throughput: Up to 5 sq.in / Sec

Components: >250,000 / Hour

Maximum board size: 22" x 20" (560 mm x 510 mm)

Clearance: 2" (50 mm) Top and bottom

Minimum component size: 0201, 01005

With high magnification option

Hardware:

Material handling:

USB 2

SMEMA

Dual direction auto width conveyor

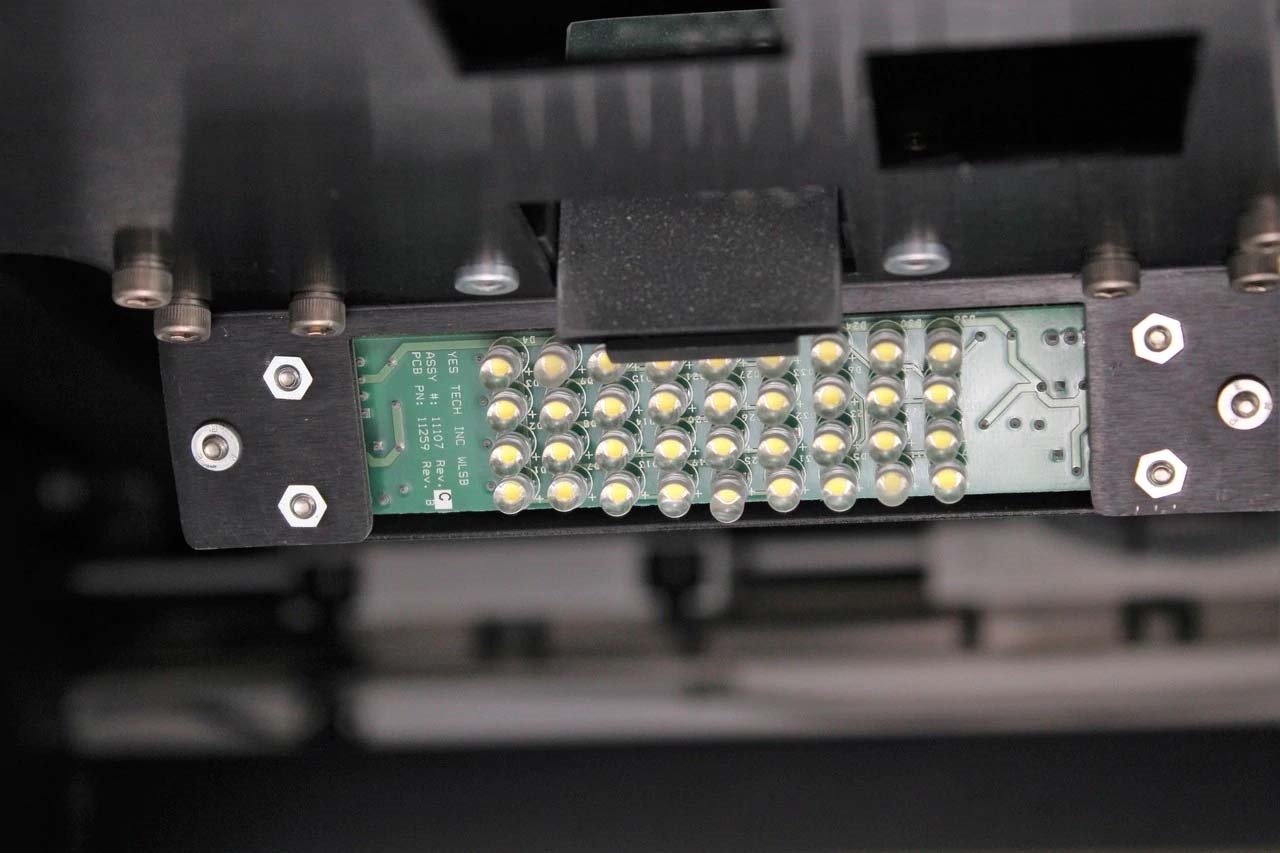

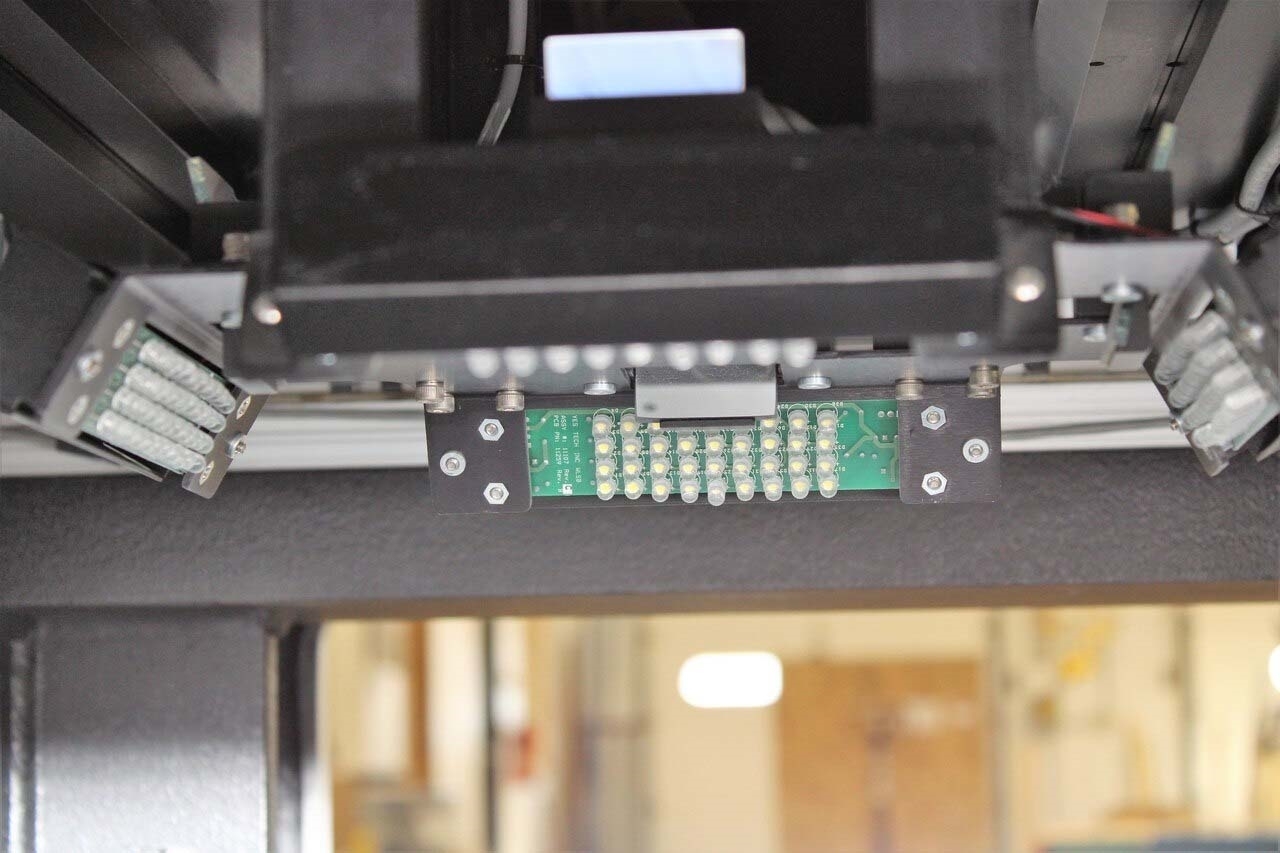

Lighting:

LED Top light

Proprietary bi-color multi-angle LED lighting

Imager:

Multiple thin camera

Mega-pixel color cameras

Resolution: 1280 x 1024

Pixel size: 25 Micron

Camera: Top

Defects detected:

Component: Position, missing, wrong, polarity, skew, tombstone

Lead: Bent, lifted, bridging

Solder: Open, insufficient, short, solder balls

Facilities:

Air input: 30 PSI min, 1/4 air hose

Power supply: 110 VAC, 50/60 Hz, 15 Amps.

NORDSON / YESTECH F1 is a state‐of‐the‐art PC board assembly and manufacturing equipment designed to accurately and efficiently produce high-quality, fully tested and functioning printed circuit board (PCB) assemblies. With its advanced automation and process control technology in a compact, easy to use machine design, it delivers improved throughput and enhanced process capability for all product manufacturing requirements. NORDSON F1 system is comprised of several main components, each playing its own critical role. The unit's manufacturing application is the foundation, offering a comprehensive and flexible set of production tools. This is supplemented by a hardware platform with precision motion and auxiliary control hardware, as well as vision, dimensional inspection and data-logging capabilities. YESTECH F1 offers fast and repeatable placement of components with the integrated delta robot. The delta robot is a six-axis tool, tightly integrated with a PC board handler and component feeders, allowing for accurate and efficient placement of components. The integrated vision cameras ensure accurate placement of components and identification of unique characteristics for part recognition. F1 also features integrated machine diagnostics and a comprehensive failure detection tool that instantly identifies, logs, and communicates when a component placement is not placed accurately. This is coupled with automated pick-and-place and test mechanisms that track assembly and diagnose faults in production pieces on-the-fly. In addition, NORDSON / YESTECH F1's effective process control software ensures that manufacturers can quickly and easily modify the entire assembly process to adapt to specific customer requirements or changing product requirements. This flexibility enables manufacturers to produce high-quality and reliable PCB assemblies with a shorter lead time. NORDSON F1 is an industry-leading asset that incorporates advanced automation and process control technology into a single, compact machine that delivers unparalleled performance for PCB assembly and manufacturing. It is the ideal choice for any PCB manufacturing operation - providing a powerful solution to produce high-quality and fully tested PCB assemblies.

There are no reviews yet