Used NORDSON / YESTECH F1 #9287523 for sale

URL successfully copied!

Tap to zoom

ID: 9287523

Automated Optical Inspection (AOI) system

Inspection capabilities:

Throughput: Up to 5 sq. in./ sec. > 250,000 components per hour

Clearance, 2”

Minimum component size: 0201, 01005 with high magnification option

Maximum board size: 22” x 20”

Defects detected:

Component: Position

Missing

Wrong

Polarity

Skew

Tombstone

Lead:

Bent

Lifted

Bridging

Solder: Open

Insufficient

Short

Solder balls

Hardware:

Material handling:

USB 2

SMEMA

Dual direction auto width conveyor

Lighting:

LED top light

Proprietary bi-color multi-angle LED lighting

Board clamps

Bottom side camera for bottom side bar codes

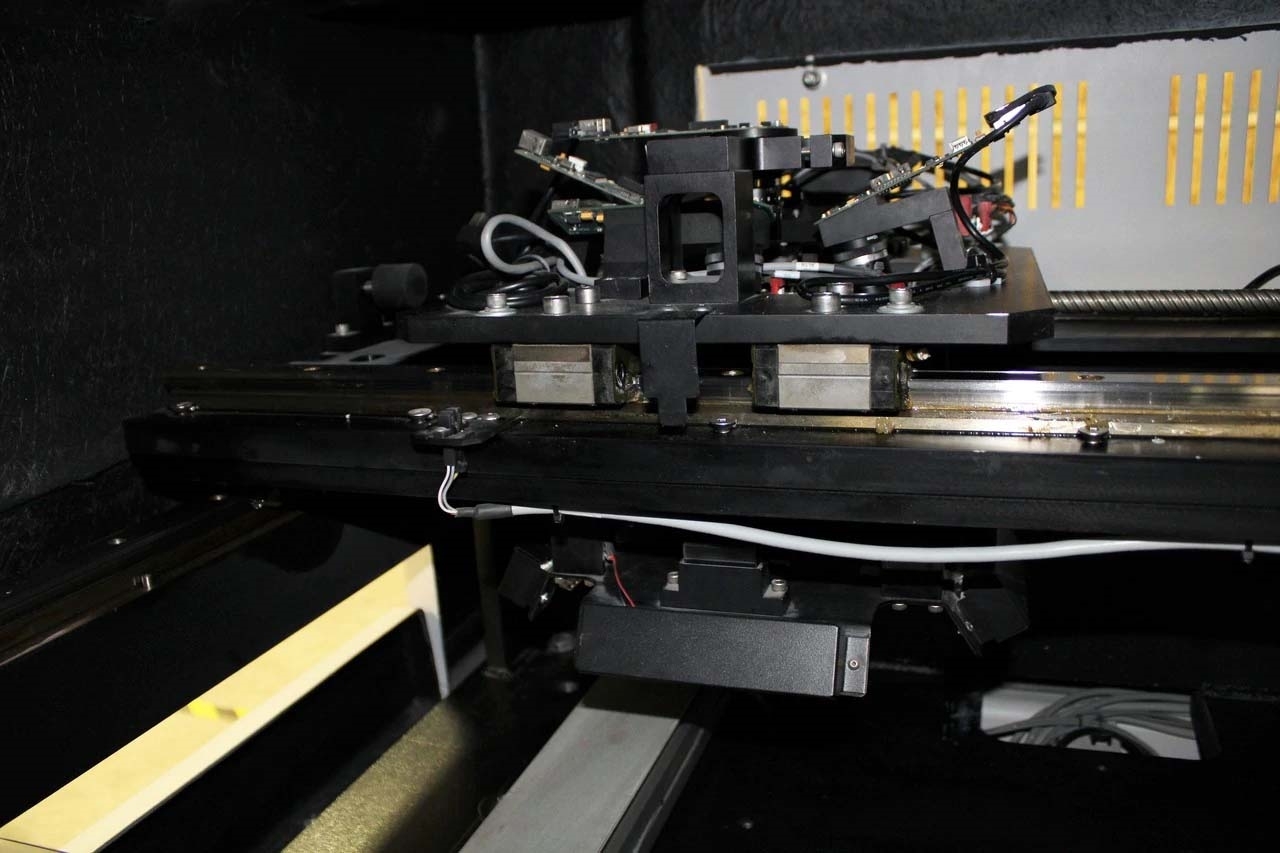

Imager:

Multiple thin camera™ mega-pixel color cameras

Resolution: 1280 x 1024

Size: 25 Micron pixel

Angle: Top, left, right and front

High magnification camera: 12 Micron

Board clamps

Operating system: Windows XP professional

Power supply:

Air input: 30 PSI min, 1/4 air hose

110 VAC, 50/60 Hz, 15 Amps.

NORDSON / YESTECH F1 PC Board Assembly and Manufacturing equipment is a high-performance, all-in-one solution that provides precise assembly and process control with data logging from start to finish. By combining automatic component placement, selective soldering, and other automated processes, NORDSON F1 is designed to reduce production time and costs. YESTECH F1 system features multitasking capabilities, delivering simultaneous operations and handling complex assembly jobs. F1 unit is equipped with a powerful, multi-tasking controller and closed-loop control of motion and processing. Automatic part fetching and component placement are performed precisely and quickly. NORDSON / YESTECH F1 comes with a variety of features to ensure quality control and to increase production efficiency, including accuracy and repeatability of components. An integrated process control monitor verifies operation time and accuracy by comparing values of selected parameters against set limits. NORDSON F1 also has integrated data logging capabilities that assist in streamlining production operations. Through the integrated data logging, errors can be quickly identified and addressed, and any problems in the production process are clearly visible. YESTECH F1 includes a user-friendly graphical user interface (GUI) to allow operators to easily monitor and control the operation of the machine while also providing quality documentation for each PC board produced. The GUI also helps to reduce operator setup time as it guides the process and provides access to maintenance procedures. Additionally, the self-testing feature, program checker, and the optional equipment package ensure that the tool operates reliably and efficiently for a variety of applications. Its quick start and commissioning time, simple programing, and automation make it particularly attractive for customers in both production and development environments. Overall, F1 PC Board Assembly and Manufacturing asset is an efficient one-stop solution for complete, error-free manufacturing. Easy to use and cost-effective, it delivers the best of both worlds: precision assembly and process control with data logging from start to finish.

There are no reviews yet