Used NORDSON / YESTECH YTV-BX #9300162 for sale

URL successfully copied!

Tap to zoom

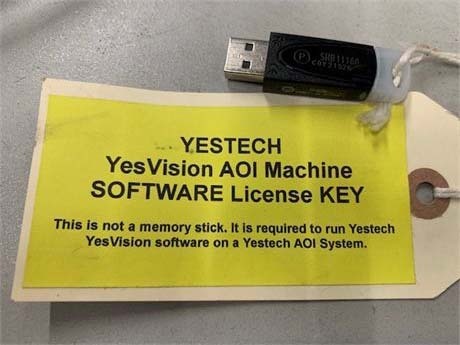

NORDSON / YESTECH YTV-BX is a comprehensively integrated surface mount technology (SMT) manufacturing equipment that provides complete turnkey solutions for printed circuit board assembly (PCBA) processes. It meets the needs of mid to large scale manufacturers by delivering reliable, high-performance results with consistent efficiency and quality throughout the production line. The system sells with an intuitive, flexible, and versatile software control unit, allowing users to make customizations to meet the specific needs of their operation. It is designed to minimize downtime and maximize throughput while providing consistent quality and precision results. The machine can handle a wide variety of material and part types, including chip and pin components, 0805 and 1206 components, axial and radial leaded components, as well as a variety of processor packages such as QFN, BGA and SIP. NORDSON YTV-BX features a high-precision transport tool that ensures quick processing for a variety of material during the board assembly process. With a unique pivot and z-axis transport, each package is precisely placed with high repeatability. The asset also includes closed-loop laser registration, which ensures accurate placement of components and eliminates the need for manual alignment. YESTECH YTV-BX includes dual-lane PCB routing and routing-transport capabilities to ensure maximum throughput. It is also capable of parallel processing for multiple PCBs, so two different product types can simultaneously be wafer-processed in one pass. The model also offers a wide array of quality control capabilities, enabling users to detect a range of defects such as shorts, opens, and solder bridges. YTV-BX utilizes an automated calibration equipment that ensures steady and efficient performance across the entire production line. This ensures that the registration and placement of components remain consistent. Additionally, the system includes vision-based defect detection and repair, so each individual part can be carefully inspected and monitored. NORDSON / YESTECH YTV-BX is designed to provide reliable and quality results throughout the entire production process. With its comprehensive set of features, NORDSON YTV-BX provides users with a cost-effective, scalable, and customization turnkey solution for their PCBA production. The unit is well-suited for mid-to-large scale manufacturers and has proven to be an essential tool for achieving consistent results and efficiency.

There are no reviews yet