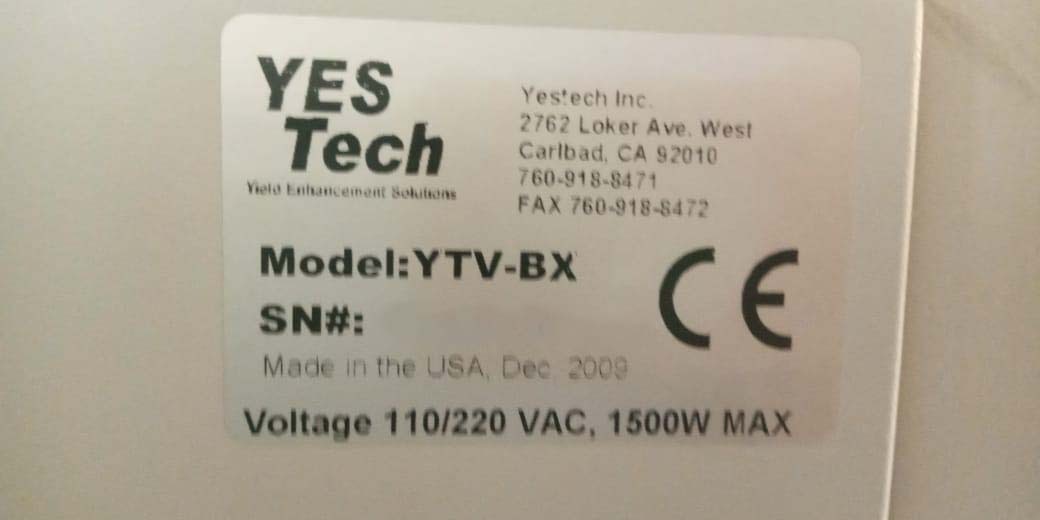

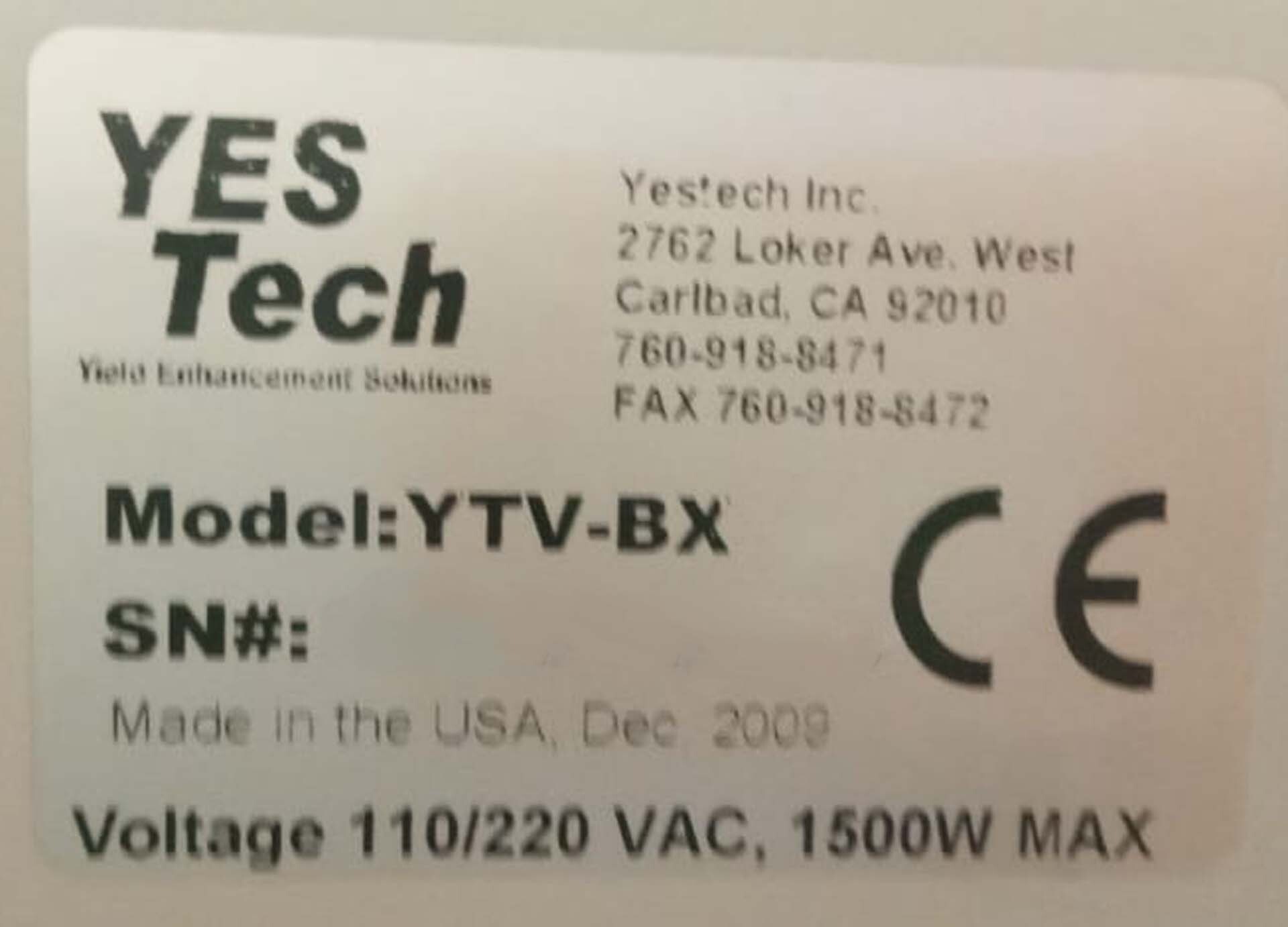

Used NORDSON / YESTECH YTV-BX #9313057 for sale

URL successfully copied!

Tap to zoom

ID: 9313057

Vintage: 2009

Inline Automated Optical Inspection (AOI) System

Power supply: 220 V

2009 vintage.

NORDSON / YESTECH YTV-BX is a highly advanced PC board assembly and manufacturing equipment built with the modern production needs in mind. This system is designed to enable advanced process chain control, inspection evaluation, and optimization of PC board assembly in an efficient and cost-effective manner. The unit consists of various modules that can be programmed to complete a wide range of assembly and manufacturing tasks. It includes a Multiline Matrix, a Built-in CCD Camera, an Indexing Conveyor Line, a Modular, Multi-zone Layer-by-Layer Array (MMLA) and a Print Box, an On-Board Servo-Controlled Vision Inspection Machine, a Hand-Held Scanner, and a Proprietary Software Suite. The Multiline Matrix module consists of individual movable pick-and-place heads or robots. It is used to assemble PC boards by moving components from one PC board to another. The CCD camera enables the tool to read the components that are being used for assembly, to detect any defects, and to provide real-time feedback for assembly quality. The Indexing Conveyor Line operates as a work table to support PC boards during assembly. The Modular, Multi-zone Layer-by-Layer Array (MMLA) module is an automated production cell that allows the user to configure the assembly process according to the specific requirements of the product. This module also includes an automated quality assurance and inspection process so that any defects or errors are detected and rectified immediately. Moreover, it includes an On-Board Servo-Controlled Vision Inspection Asset that uses visual recognition techniques to inspect components and to give real-time feedback to help in the debugging process. The Print Box is capable of applying adhesive and solder to PC boards and components, ensuring that the boards and components secure into place. The Hand-Held Scanner is an optional feature that allows the operator to manually scan components prior to assembly, thus ensuring accuracy. Finally, the Proprietary Software Suite allows the user to create and manage PC board assembly projects, track progress, and view detailed reports on the production run. Overall, NORDSON YTV-BX model enables for precise and efficient PC board assembly. With its modular features and innovative vision inspection process, it is a perfect solution for increasing the efficiency and quality of PC board assembly in any production cycle.

There are no reviews yet