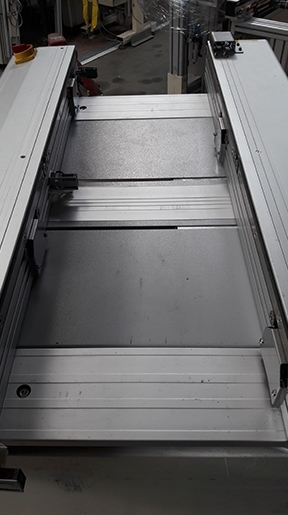

Used NUTEK NTM 410L-1000-2-FW #9262715 for sale

URL successfully copied!

Tap to zoom

ID: 9262715

Vintage: 2015

Conveyor

Specifications:

Length: 1000 mm

Width: 730 mm

Useful passage width: 70 - 407 mm

(2) Segments

Length: 500 mm

Fixed speed

Flat belts

Automatic width adjustment via upstream equipment

Conveying direction: Left to right

Conveying height: 950 mm +/- 25 mm

Disconnector

Light button

Stop light button

Stop / Send button for inspection

Emergency stop

SMEMA 2 Communication

SMEMA Cord

Color: RAL9002

Power supply: 230 Volts (1P + N + T)

2015 vintage.

NUTEK NTM 410L-1000-2-FW is a pc board assembly and manufacturing equipment designed for fast and efficient production of high quality printed circuit boards. This system consists of two piece pick and place machines with 4 heads each that can place more than 1,200 components per minute, enabling a total production of 2000 boards per hour. In addition, the unit features integrated component feeding, component verification, machine vision and circuit board testing capabilities. NTM 410L-1000-2-FW features an automated component feeder to ensure that the appropriate components are available when needed. The component feeder has internal storage to hold a wide variety of parts and can be programmed to feed components in the correct quantity and configuration as needed. This machine also has automated optical inspection of components to ensure their accuracy and proper assembly. The vision tool examines every component prior to placement to ensure that it meets the standards of the board manufacturer. The vision asset also inspects every component and board after they are placed for accurate placement and proper soldering. The model also features an integrated circuit board testing feature that can quickly test assembled boards for errors and ensure that they are functioning correctly. The testing software can also be programmed to detect certain common errors in the code to quickly identify and remedy issues. NUTEK NTM 410L-1000-2-FW also includes a self-moving trolley that moves along the production line and is capable of carrying as many as five hundred boards at one time. This allows for faster, more efficient board transfer and production. In conclusion, NTM 410L-1000-2-FW is a state of the art pc board assembly and manufacturing equipment that is designed to provide high quality and efficient production of printed circuit boards. With automated components feeding, component verification, machine vision and circuit board testing, this system ensures efficient and accurate production of printed circuit boards.

There are no reviews yet