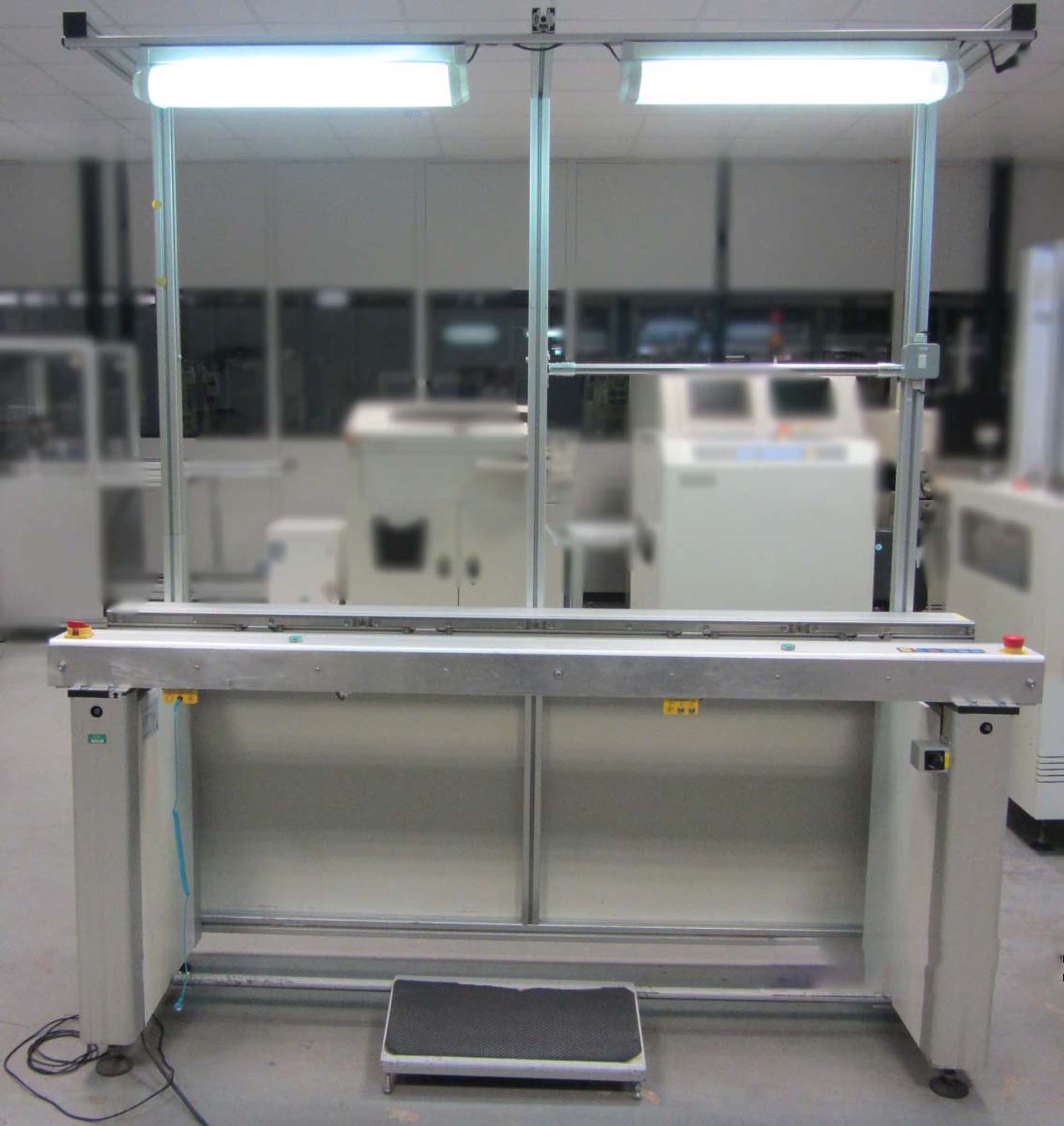

Used NUTEK NTM 530WSM-2000-4 #9267640 for sale

URL successfully copied!

Tap to zoom

NUTEK NTM 530WSM-2000-4 is a complete PC board assembly and manufacturing equipment for medium- to high-volume production. The system comprises a base unit, a productivity suite, a traceability and monitoring unit, and an optional vision machine. The base unit is a production-ready tool with up to twelve feeders that allow the simultaneous placement of components across the full line-up of the embedded circuit boards. It includes an integrated vision asset, placement accuracy up to 0.02 mm, and high-speed, double-track pick-and-place operation. The model is capable of up to 120,000 parts per hour and up to 2,000 component placements per minute. The productivity suite includes a library of pre-programmed components to streamline the set-up process, as well as an intuitive graphical user interface that facilitates easy programming of the equipment. The optional vision system is designed to inspect parts and verify correct placements, as well as measure component dimensions. The traceability and monitoring unit is designed to identify, trace, and monitor all components. It helps to ensure the reliability of the parts used and compliance with regulatory standards. In addition to the benefits provided by the core components of NTM 530WSM-2000-4, the machine can also integrate with other production lines as well as external customers, suppliers, and other stakeholders. Additionally, built-in security features enable data protection and ensure that production data remains secure. The combination of the core components of NUTEK NTM 530WSM-2000-4 and the many optional features results in an efficient, highly reliable, and cost-effective tool that helps companies meet their production demand efficiently and accurately. The asset is tailored to specific customer requirements, making it an ideal solution for medium- to high-volume production needs.

There are no reviews yet